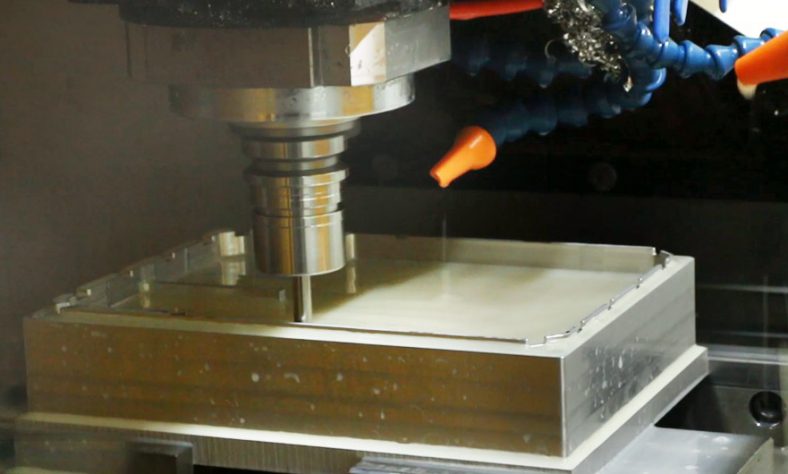

What Machining Methods Can be Used for CNC Smart Watch Case?

In the fast-paced world of smartwatches, a case is more than just a case, it’s an expression of style and innovation. From gleaming metal finishes to sleek ceramic designs, each smartwatch case is the result of meticulous manufacturing techniques. In this article, we take you on a journey into the fascinating world of smartwatch casing …