Difference Between Transverse Turning and Longitudinal Turning

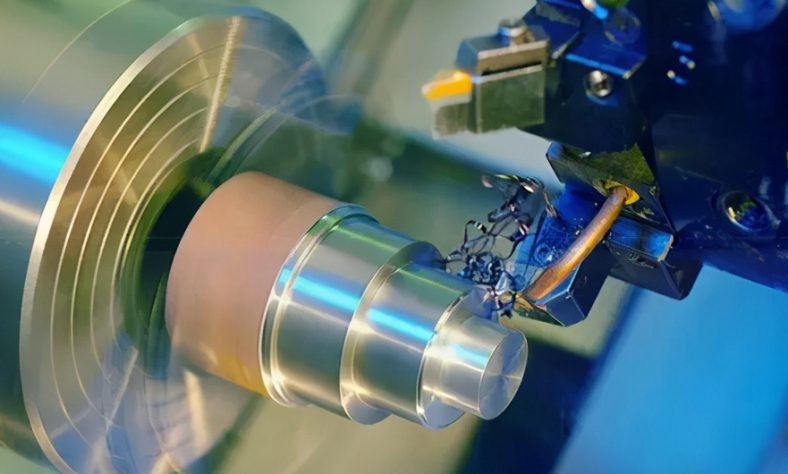

CNC lathe is one of the most widely used CNC machine tools. It is mainly used for machining symmetrical rotary parts, such as shaft parts, inner and outer cylindrical surfaces of disk parts, inner and outer conical surfaces with arbitrary cone angles, complex inner and outer …