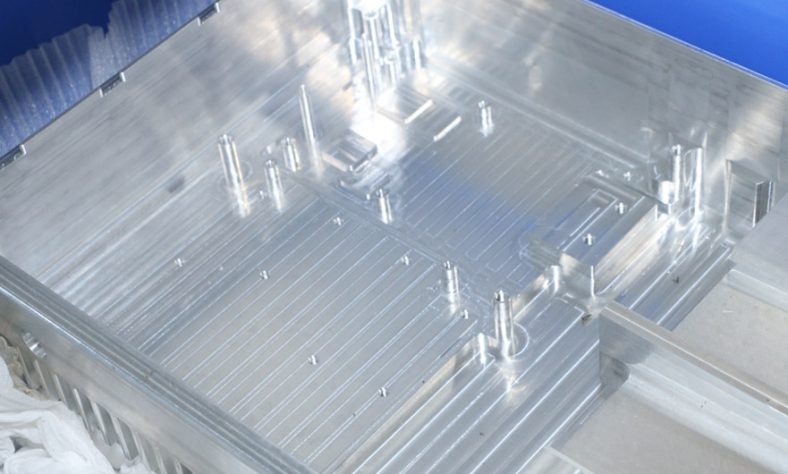

How does CNC machining factory use high-gloss tools for milling machining?

In the process of CNC milling machining, the surface finish of many parts is affected by factors such as material hardness, cutting tools, machine tool feed, and cutting fluid. Below, we conduct research on tools to help our customers improve the surface quality of parts. Not all materials can be milled with high-gloss …