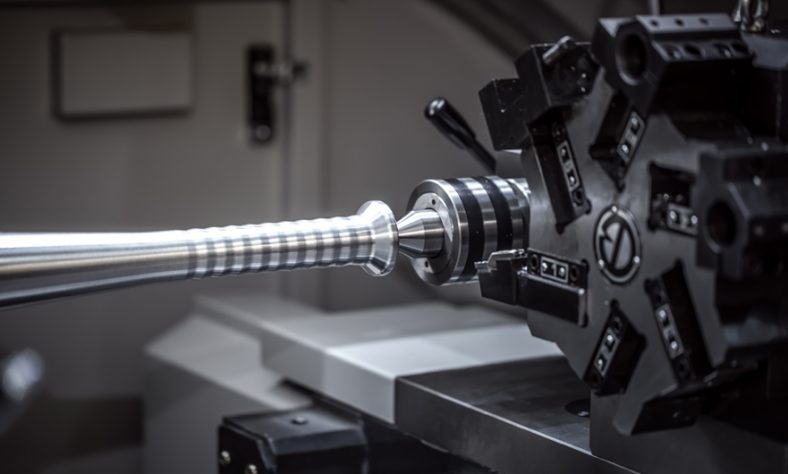

Why is it So Difficult for a Small CNC Machining Factory to Process 40 Precision Machined Parts in a Set of Finished Products?

Scale and Challenge: Why 40 Precision Machined Parts Challenge Small CNC Machining Shops In the manufacturing industry, CNC machining has become a key technology for precision parts manufacturing. However, for small CNC machining factories, when a set of products contains 40 precision machined parts, they will face a series of technical and resource …