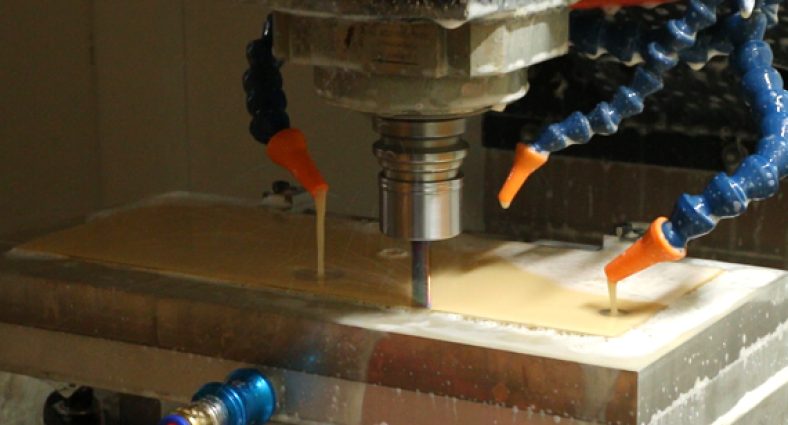

Can CNC Machining Manufacturers Provide Samples and Small Batch Production Services?

Yes, CNC machining manufacturers commonly offer both sample production and small batch manufacturing services to cater to a wide range of customer needs. Here’s an overview of these services: Sample Production: CNC machining manufacturers often provide sample production services, allowing customers to receive a small quantity of prototypes or test parts before …