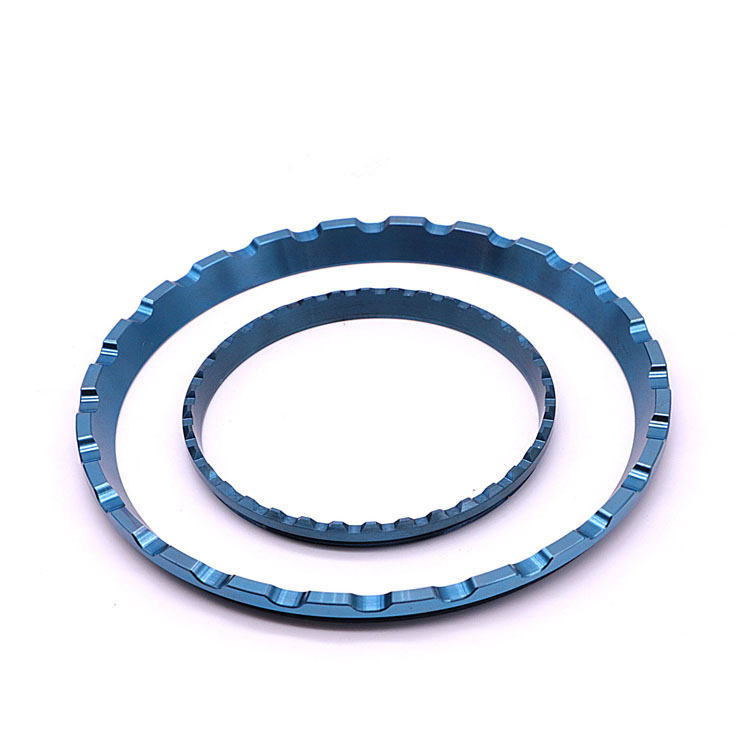

1. Anodizing of aluminum CNC machining parts

Anodic oxidation: mainly anodic oxidation of aluminum, which uses electrochemical principles to form a layer of aluminum oxide film on the surface of aluminum and aluminum alloys. This layer of oxide film has special characteristics such as protection, decoration, insulation, wear resistance, etc., and is generally suitable for aluminum CNC machining parts.

Process flow:

Single color, gradient color: polishing/sandblasting/drawing→degreasing→anodizing→neutralization→dyeing→sealing→drying

Two-color: ① Polishing/sandblasting/drawing → degreasing → masking → anodizing 1 → anodizing 2 → sealing → drying

②Polishing/sandblasting/drawing→oil removal→anodizing 1→radium engraving→anodizing 2→sealing→drying

Technical Features:

1. Increase strength;

2. Realize any color except white;

3. Realize nickel-free sealing and meet the nickel-free requirements of Europe, the United States and other countries.

Technical difficulties and key points for improvement:

The yield level of anodic oxidation is related to the cost of the final product. The key to improving the oxidation yield is the appropriate amount of oxidant, appropriate temperature and current density. This requires structural parts manufacturers to continuously explore and seek breakthroughs in the production process.

2. Electrophoresis

Electrophoresis: used for stainless steel, aluminum alloy, etc., which can make the product present various colors and maintain the metallic luster, while enhancing the surface performance and having good anti-corrosion performance.

Process flow:

pretreatment→electrophoresis→drying

Technical Features:

1. Rich colors;

2. No metal texture, suitable for sandblasting, polishing, wire drawing, etc.;

3. CNC machining in a liquid environment can realize surface treatment of complex structures;

4. The process is mature and can be mass-produced.

Disadvantages:

The ability to cover up defects is average, and the electrophoresis of die-casting parts requires high pre-treatment.

3. Micro arc oxidation (MAO)

Micro-arc oxidation: a process in which a high voltage is applied in an electrolyte solution (usually a weakly alkaline solution) to form a ceramic surface film layer. This process is the result of the synergistic effect of physical discharge and electrochemical oxidation.

Process flow:

pretreatment → hot water washing → MAO → drying

Technical Features:

1. Ceramic texture, dull appearance, no high-gloss products, delicate hand feeling, anti-fingerprint;

2. Wide range of substrates: Al, Ti, Zn, Zr, Mg, Nb, and their alloys;

3. The pre-treatment is simple, the product has excellent corrosion resistance, weather resistance, and good heat dissipation performance.

Shortcoming:

At present, the color is limited, only black and gray are relatively mature, and bright colors are currently difficult to achieve; the cost is mainly affected by high power consumption, which is one of the high costs in surface treatment.

4. PVD vacuum plating

Physical vapor deposition (Physical vapor deposition, PVD): It is an industrial manufacturing process that mainly uses physical processes to deposit thin films.

Process flow:

Cleaning before PVD → vacuuming in the furnace → target washing and ion cleaning → coating → coating is completed, cooling out of the furnace → post-processing (polishing, AFP)

Technical Features:

PVD (Physical Vapor Deposition, Physical Vapor Deposition) can coat metal surfaces with high-hardness and high-wear-resistance cermet decorative coatings

5. Electroplating

Electroplating: It is a technology that uses electrolysis to attach a layer of metal film to the surface of the metal to prevent corrosion, improve wear resistance, conductivity, reflectivity and enhance the appearance.

Process flow:

pretreatment → cyanide-free alkali copper → cyanide-free cupronickel tin → chrome plating

Technical Features:

1. The coating has high gloss and high-quality metal appearance;

2. The base material is SUS, Al, Zn, Mg, etc.; the cost is lower than PVD.

Disadvantages:

Poor environmental protection, high risk of environmental pollution.

6. Powder coating

Powder spraying: use powder spraying equipment (electrostatic spraying machine) to spray powder coating on the surface of the workpiece. Under the action of static electricity, the powder will be evenly adsorbed on the surface of the workpiece to form a powdery coating; Bake leveling and curing, and become the final coating with different effects (different types of powder coating effects).

Process flow:

Loading → electrostatic dust removal → spraying → low temperature leveling → baking

Technical Features:

1. Rich colors, high gloss and matte optional;

2. Low cost, suitable for architectural furniture products and shells of heat sinks, etc.;

3. High utilization rate, 100% utilization, environmental protection;

4. Strong ability to cover defects;

5. Can imitate wood grain effect.

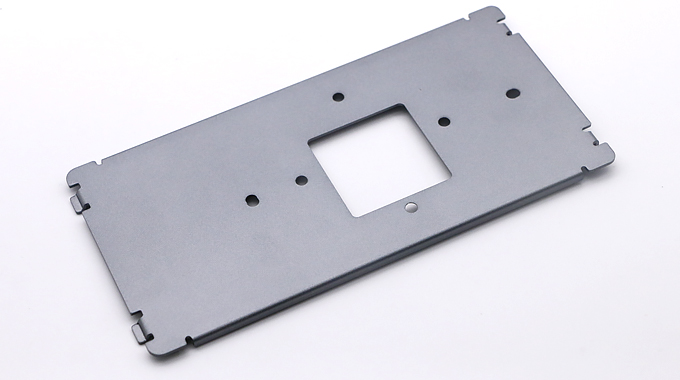

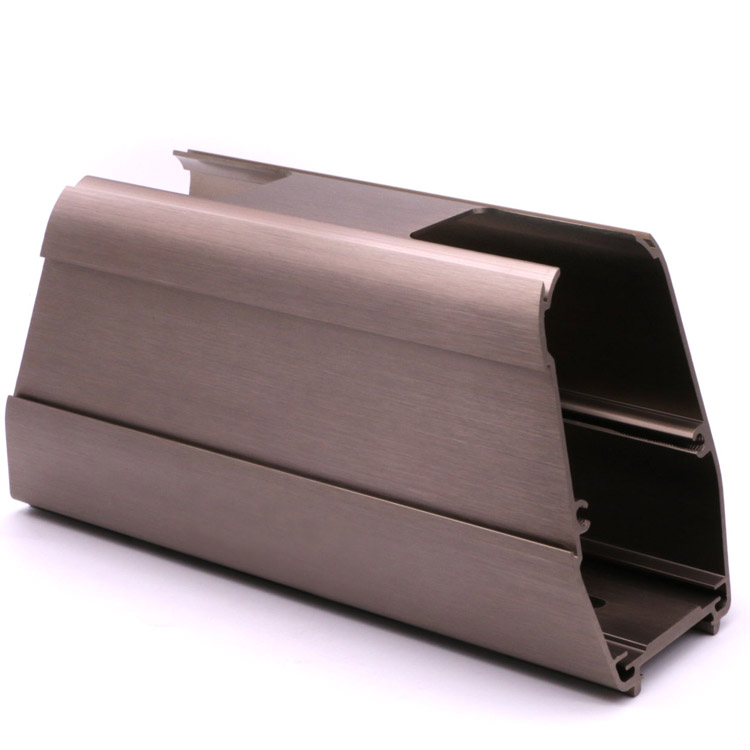

7. Metal wire drawing

Wire drawing: It is a surface treatment method that forms lines on the surface of CNC parts by grinding products to achieve a decorative effect. According to the different textures after wire drawing, it can be divided into: straight wire drawing, chaotic wire drawing, corrugated, and swirling.

Technical Features:

The brushed treatment can make the metal surface obtain a non-mirror-like metallic luster, and the brushed treatment can also eliminate the slight flaws on the metal surface.

8.Sandblasting

Sand blasting: It uses compressed air as the power to form a high-speed jet beam to spray the spray material onto the surface of the workpiece to be treated at high speed, so that the appearance or shape of the outer surface of the CNC part surface changes, and a certain degree of cleanliness and different roughness are obtained. a process.

Technical Features:

1. Realize different reflective or matte;

2. It can clean the tiny burrs on the surface of the workpiece and make the surface of the workpiece more smooth, eliminating the harm of burrs and improving the grade of the workpiece;

3. Clear the residual dirt left over from the pre-treatment, improve the finish of the CNC parts, and make the workpiece reveal the uniform metal color, making the appearance of the workpiece more beautiful and attractive.

9. Polishing

Polishing: the modification of the surface of CNC parts by using flexible polishing tools and abrasive particles or other polishing media.

Process flow:

For different polishing processes: rough polishing (basic polishing process), intermediate polishing (finishing process) and fine polishing (glazing process), selecting the appropriate polishing wheel can achieve the polishing effect and improve the polishing efficiency at the same time.

Technical Features:

Improve the dimensional accuracy or geometric shape accuracy of the workpiece, get a smooth surface or mirror gloss, and at the same time eliminate gloss.

10. Etching

Etching: Usually refers to etching, also known as photochemical etching, which refers to removing the protective film of the area to be etched after exposure to plate making and development, and contacting chemical solutions during etching to achieve the effect of dissolution and corrosion, forming concave-convex or hollow-out molding effects.

Process flow:

Exposure method: The project prepares the material size according to the graphics-material preparation-material cleaning-drying→film or coating→drying→exposure→development→drying-etching→release→OK

Screen printing method: cutting → cleaning plate (stainless steel and other metal materials) → screen printing → etching → stripping → OK

Technical Features:

1. Can carry out micro-processing of metal surface;

2. Give the metal surface a special effect;

Shortcoming:

Most of the corrosive liquids (acids, alkalis, etc.) used in etching are harmful to the environment.

The above are ten common surface treatment methods, I hope it will be helpful to you.