Fixtures are always used in CNC machining now. Fixtures are mainly used as auxiliary tools for controlling position or movement (or both) to help us better CNC machining parts, so what should we pay attention to when using fixtures for CNC machining? The following CNCMF summarizes 7 points for attention.

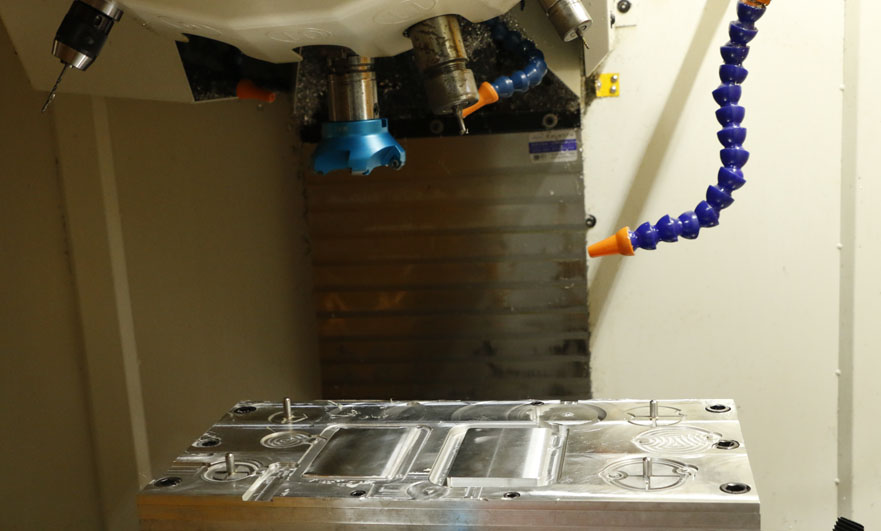

1. Inspection Before CNC Machining:

Before CNC machining, it is necessary to check whether the clamping direction of the workpiece is correct, whether the position in the mold is the same as required, whether the fixture hinders the processing, whether the tools used are complete, the determination of the workpiece coordinate positioning datum, etc.

2. Grab the Knife, Play the Knife, and Drop the Knife:

If you encounter the phenomenon of large amount of feed, too long tool clamping length, and small tool diameter, it is easy to have inaccurate dimensions when processing the same position as the corner radius and tool radius. The knife is layered to clear the corners, and then replaced with a larger knife to solve the problem on the side.

3. Mold and Product Matching Tolerance:

1). The matching positioning of the upper and lower shells is guaranteed by the seam, and the tolerance of the concave seam and the convex seam is generally 0.1 on one side;

2). Usually, the shape of accessories on the large body of the shell (such as a transparent mirror) is 0.1-0.2 smaller than that of the large body; the shape of movable accessories (such as buttons) on the body is 0.1-0.5 smaller than that of the large body;

3). If the surface shape of the accessories is consistent with the surface shape of the main body, it can be trimmed from the corresponding position on the main body surface.

4.CNC Machining Overcut Inspection:

CNCMF reminds that overcutting is a frequent problem, and special attention should be paid to it. The solution is to simulate the tool path once, and check it repeatedly in various directions. The tool path that has not been checked is not allowed to be machined. When the shape is CNC milled, if the cutting point is not selected properly, overcutting will occur, which can be avoided by changing the cutting point.

5. Selection of Cutting Point:

When writing the tool path, the knife can be cut at any height and position specified. When the first cut is just started to process, the amount of cutting is often relatively large, which is likely to cause the knife to break or bounce. At this time, the lower knife position can be opened rough or The knife on the first layer is empty, and the knife should be cut outside the material as much as possible. This problem must be paid attention to.

6. Contents of CNC Machining Work Order:

In order to facilitate communication with the operator, the processing sheet (program paper) should include: CNC program name, tool type, tool diameter, tool clamping length, CNC machining allowance, tool path type (rough or light tool), original graphic file name (such as cnc1c:mc9acb01s.mc9), if there are special CNC processing requirements, please attach a schematic diagram.

7. Die bad clamping direction:

One of the four guide bolt holes (guide post holes) on the mold base is distributed asymmetrically. The direction of the mold base before and after clamping must be clear so that the directions of the front and rear molds match. There is a reference on each template. After the CNC machining is completed, when the front and rear molds are combined, the reference should be aligned with the reference, and the original mold base should be sampled.

The above is the detailed explanation of the seven precautions for CNC fixture machining, and I hope it will be helpful to everyone.