We usually say that it is better to choose a good pipe, especially for a CNC machining factory that processes parts according to drawings, how do we choose a suitable CNC machining supplier, and what should we pay attention to when choosing a CNC machining supplier?

First recommend a CNC machining supplier attractive model:

Another formula is recommended: CNC machining supplier performance = willingness x ability

Based on the experience of all purchasing managers, we have summarized the following points:

1. Look at the needs

Looking at the requirements of CNC parts machining, CNC parts have low precision requirements and a large number of CNC parts, mainly looking for suppliers with good coordination, low prices, and large production capacity, and those with high CNC parts requirements, depending on the CNC machining supplier’s equipment and CNC machining capabilities , process capability, testing capability and related experience, etc.

2. Look at will

If it is CNC machining of small batches and multiple varieties, the key point is to look at the willingness of CNC machining suppliers to cooperate and the development direction of the supplier boss, that is, the industry matching degree. Products with multiple varieties and small batches are not suitable for suppliers with running volume. In addition, it depends on the positioning of the suppliers, that is, their target customers, so that they are the right match.

3. Ability to see

The capabilities include design capabilities, proofing capabilities, mass production capabilities, assembly capabilities, and testing capabilities. You must select a CNC processor with corresponding capabilities based on your needs for CNC machining suppliers.

4. Watch delivery

To study their value stream, the output rate and utilization rate of key equipment, the flexibility of production capacity, etc., you can look at the timely delivery rate data of their other customers, and judge whether the production capacity is based on his current order situation, the number of customers, etc. Saturation, whether there is excess capacity to guarantee the delivery of your order. In addition, order management and order tracking capabilities will also affect delivery, depending on whether the CNC machining supplier has a dedicated person or a production management system.

5. Look at the cost

It depends on the equipment value, average output, efficiency, procurement cost, per capita output, management cost, etc. of CNC machining suppliers. For the cost composition of CNC machining and sheet metal parts, it is mainly the labor cost of equipment, CNC machining time, Material fee, table fee, management fee, profit, etc. On the one hand, it is necessary to understand the CNC machining process, and on the other hand, it is necessary to collect market rates and material costs, and have the ability to do cost analysis. Specifically how to do cost analysis, we will have a special cost analysis discussion, please continue to pay attention.

6. Look at the package

For CNC machining suppliers, pay attention to the supplier’s supporting capabilities, such as surface treatment, heat treatment, spraying, and outsourcing capabilities for a single process, especially for many types of materials, surface treatment and heat treatment. important.

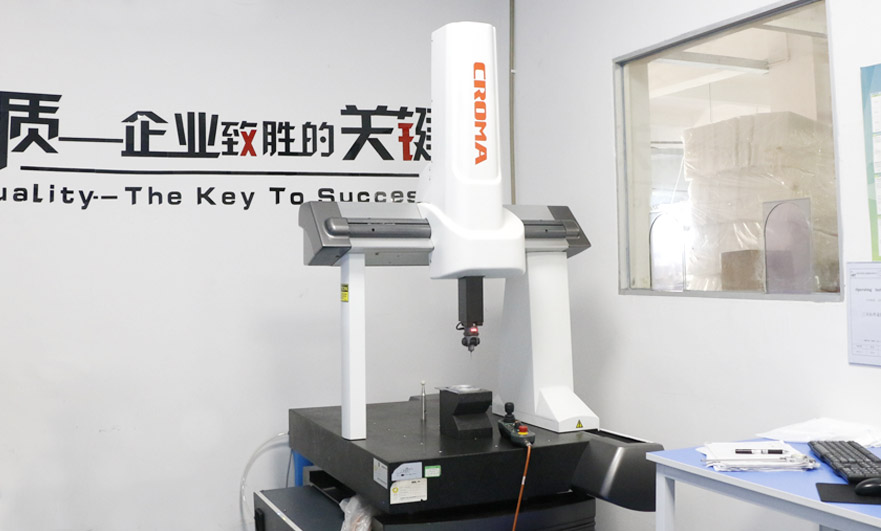

7. Look at the quality

Look at the quality awareness of CNC machining suppliers, whether there are full-time quality personnel, whether on-site process inspection, sampling inspection, final inspection and other processes are implemented, whether there is a clear quality control process, whether there is suitable inspection equipment and inspection capabilities, and unqualified how to handle the product.

8. Watch management

Looking at the management level of the CNC machining company, people are the foundation of everything else, and look at the industry experience, promotion and mobility of these people.

9. Look at the environment

In the CNC machining and sheet metal industries, it depends on the handling of hazardous chemicals, whether the EIA and RoHS certificates are properly managed, so as to avoid unnecessary risks.

The above is just a summary of the CNCMF CNC machining factory. If you want to know more about CNC machining, you can contact us: [email protected] to negotiate with us.