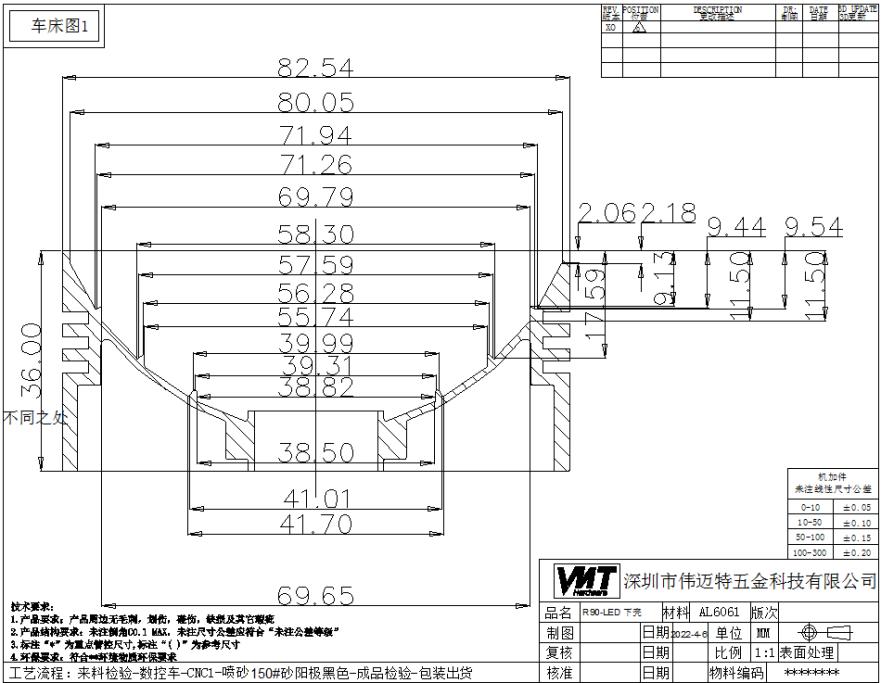

Tolerance is the acceptable range for the designer to determine the size based on the form, fit and function of the CNC part. Understanding how CNC machining tolerances affect cost, choice of manufacturing process, inspection options and materials can help you better determine CNC machining product designs.

1. Tighter tolerances mean higher costs

It is important to remember that tighter tolerances are more costly due to increased scrap, additional fixtures, special measuring tools and/or longer cycle times, as machines may need to be slowed down to maintain tighter tolerances. Depending on the tolerance callout and the geometry associated with it, the cost can be more than double that of maintaining standard tolerances.

Global geometric tolerances can also be applied to CNC part drawings. Depending on the geometric tolerance and the type of tolerance applied, additional costs may be incurred due to increased inspection time.

The best way to apply tolerances, when design criteria need to be met to minimize cost, is to apply tight or geometric tolerances only to critical areas.

2. Tighter tolerances may mean changes in the manufacturing process

Specifying tighter tolerances than standard tolerances can actually change the optimum manufacturing process for a CNC part. For example, a hole that can be made on an end mill within one tolerance may need to be drilled or even ground on a lathe within tighter tolerances, adding to setup costs and lead times.

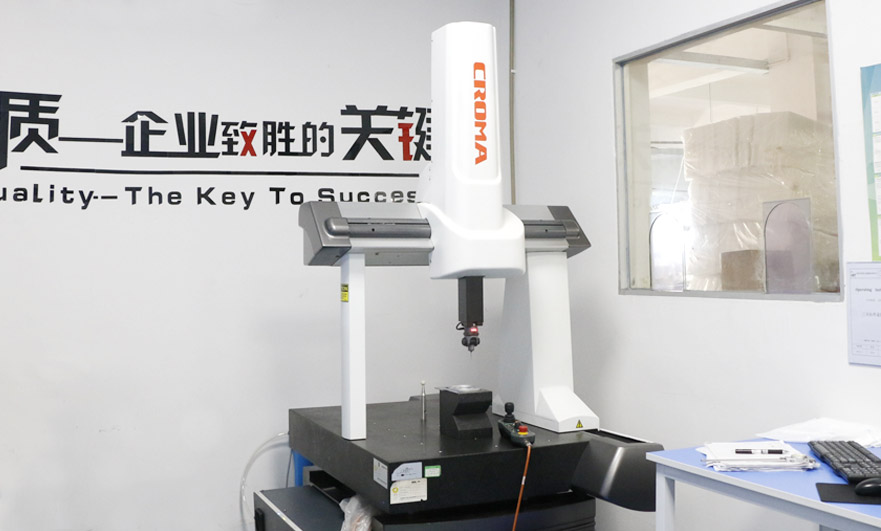

3. Tighter tolerances can change inspection requirements

Remember, when adding a tolerance to a part, you should consider how the feature will be inspected. If a feature is difficult to machine, it is likely also difficult to measure. Certain functions require specialized inspection equipment, which can increase CNC part cost.

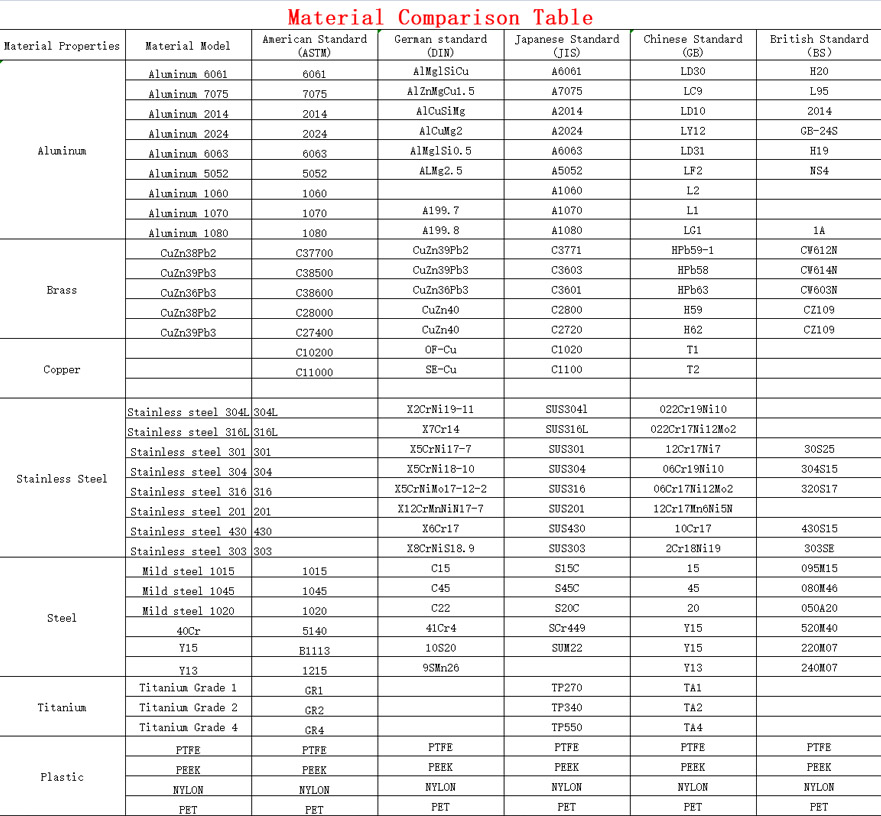

4. Tolerance depends on material

The difficulty of CNC machining a part to specific tolerances can be very material dependent. In general, the softer the material, the more difficult it is to maintain the specified tolerances due to the material bending as it is cut. Plastics such as nylon, HDPE, and PEEK may not hold the tight tolerances of steel or aluminum without special tooling considerations.

The above is the knowledge about the tolerance of CNC parts, I hope it will be helpful to you.

Source:About CNC Part Tolerance