What does the acceptance of precision CNC machining parts include? Specifically, including acceptance requirements and acceptance procedures, etc., today we will introduce the content of the two parts of acceptance requirements and acceptance procedures, as follows.

Acceptance requirements for precision CNC machining parts

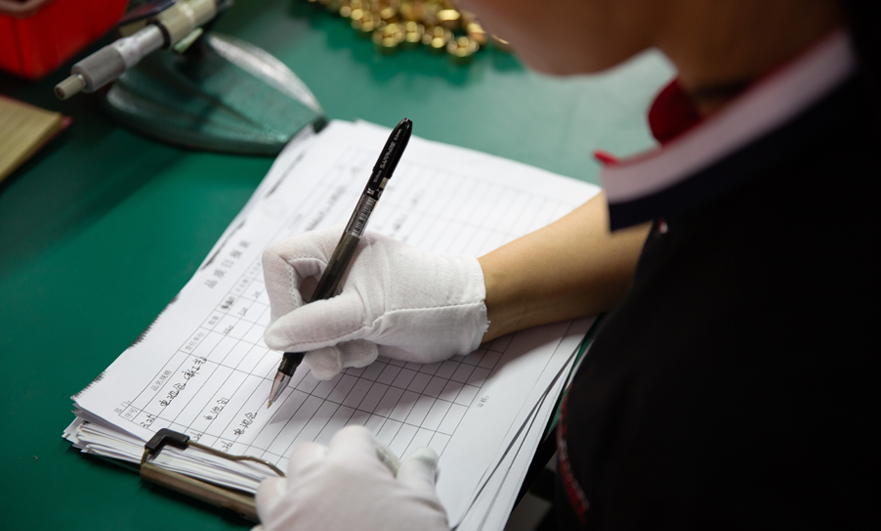

1. Visual inspection

(1) Check whether the finish of CNC machined parts meets the requirements of the drawings.

(2) Check whether the surface of the CNC machined parts is damaged, rusted, bruised and whether the thread shape and angle are correct.

(3) If the above problems are found, detailed records should be made for future reference.

2. Acceptance of the quantity of precision CNC machining parts

(1) Based on the supply contract and the CNC machining voucher, strictly check the material, specification and quantity of the CNC machining parts against the drawings, and check and check them one by one.

(2) Do a good job of quantity acceptance records, indicating the acceptance location, time, participants, types, product names, expected and actual arrival quantities.

3. Quality acceptance of precision CNC machining parts

(1) Assemble in strict accordance with the regulations and procedures required by the final assembly drawings.

(2) Records should be carefully made during quality acceptance. If there is a quality problem in the CNC machining parts, the outsourced CNC machining unit shall be notified in writing of the details. Whether to return or replace it depends on the situation.

(3) If there are special requirements, you can find the CNC machining unit for joint acceptance and assembly, and the acceptance document can be signed only after the installation is qualified.

Acceptance procedures for precision CNC machining parts

1. After the precision CNC machined parts are received, a full-time acceptance person will be dispatched to check the material, specification, model and quantity of the CNC machined parts according to the requirements of the contract and the drawings.

2. The acceptance period is generally 1-2 days. In special cases, it depends on the effect of use. If there is a quality problem, you can return the goods to the CNC machining unit, make a claim, and bear the economic loss to the CNC machining unit.

3. The CNC machining contract signed by the general non-production department will be directly checked and accepted by the using department, and the acceptance report will be filled out.

4. For CNC machined parts that are not qualified, the acceptance personnel must go through the inspection and return procedures within the specified acceptance period.

5. For the acceptance of special precision CNC machining parts, the full-time acceptance personnel will organize relevant personnel to jointly accept and accept, and fill in the acceptance report in detail. For the CNC machined parts that are not qualified for acceptance, the inspection application form should be filled in in detail, as a condition for improving the precision of CNC machining and to determine the direction of selection of CNC parts outsourcing CNC machining factories in the future.

The above is just the opinion of the CNCMF CNC machining factory, if you have a better one, you can contact us: [email protected] to discuss with us.