What Aluminum Material Grade?

Aluminum alloys are identified by a combination of numbers and letters that make up their alloy designation or grade. This system helps to categorize and describe the specific alloy composition and properties. Here’s a breakdown of the typical aluminum alloy designation format:

Series Number: The first digit(s) indicate the alloy series. For example:

Series 1: Pure aluminum

Series 2: Aluminum-copper alloys

Series 3: Aluminum-manganese alloys

Series 5: Aluminum-magnesium alloys

Series 6: Aluminum-magnesium-silicon alloys

Series 7: Aluminum-zinc alloys

Series 8: Other alloys

Subseries Number (if applicable): Some alloys within a series have additional digits to further specify the alloy composition.

Alloying Elements: Letters or symbols following the series and subseries (if present) indicate specific alloying elements. For example, “T6” indicates that the alloy has undergone heat treatment for increased strength.

Here are a few examples of aluminum alloy designations:

6061-T6: This designation refers to a heat-treatable aluminum-magnesium-silicon alloy with additional elements for strength. It is known for its versatility and is commonly used in structural applications.

5052-H32: This designation denotes a non-heat-treatable aluminum-magnesium alloy. It has good corrosion resistance and is often used in marine and automotive applications.

1100-O: This indicates pure aluminum in the 1000 series. The “O” stands for annealed, indicating it has not undergone heat treatment and is in its softest state.

These designations help engineers and manufacturers select the right aluminum alloy for specific applications based on factors like strength, corrosion resistance, formability, and other properties.

What are the Aluminum Alloy Series Materials?

Aluminum alloys come in various series, each with its own unique properties and applications. Here are some common aluminum alloy series:

1000 Series: These are essentially pure aluminum and are used for their excellent corrosion resistance. They are often used for chemical equipment and food processing.

2000 Series: Known for their high strength and excellent machining characteristics, these alloys are often used in aerospace applications.

3000 Series: These alloys have good formability and corrosion resistance. They are often used for cooking utensils, heat exchangers, and more.

5000 Series: These alloys are known for their excellent corrosion resistance and are often used in marine and automotive applications.

6000 Series: Known for their versatility, these alloys are used in a wide range of applications, including structural components and extrusions.

7000 Series: These alloys are known for their high strength and are often used in aerospace and sporting equipment.

8000 Series: These alloys are less common but offer unique properties, including good formability and weldability.

Each series encompasses a range of specific alloy compositions with varying characteristics to suit different industrial and commercial needs. The choice of alloy depends on the requirements of the specific application, such as strength, corrosion resistance, and formability.

Aluminum Alloy Materail Forms

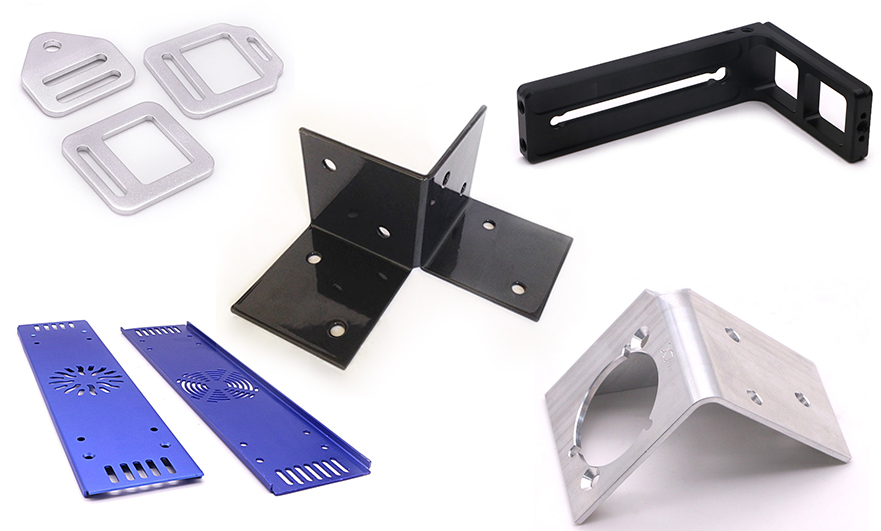

The combination of aluminum alloy forms and metal forming processes allows for the creation of a wide range of aluminum components with various shapes and characteristics. Here’s an overview of some common aluminum alloy forms and the metal forming processes used with them:

Aluminum Alloy Forms:

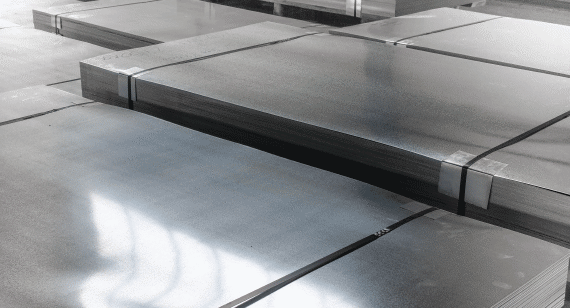

Sheet: Thin, flat pieces of aluminum. Commonly used for panels, covers, and lightweight structures.

Plate: Thicker than sheets, plates are used for heavier-duty applications that require strength and stability.

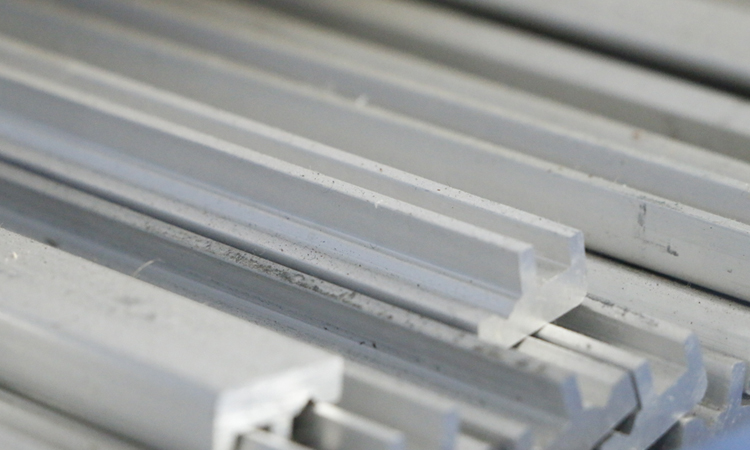

Bar: Solid bars of aluminum with various cross-sectional shapes, like round, square, or hexagonal. Used for machining, fasteners, and structural components.

Rod: Cylindrical bars, often used for applications where corrosion resistance is important.

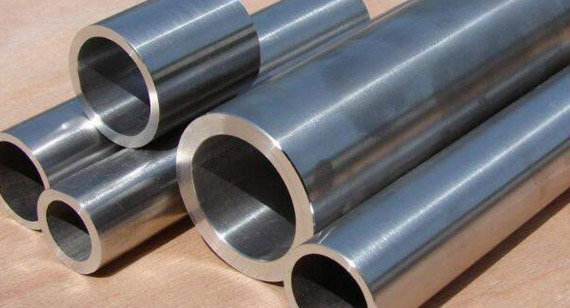

Tube: Hollow cylindrical shapes, available in various diameters and wall thicknesses. Used in tubing systems, structural components, and heat exchangers.

Extrusion: Aluminum is pushed through a die to create complex cross-sectional shapes. Extrusions are commonly used for frames, profiles, and architectural components.

Aluminum Alloy Metal Forming process

Aluminum alloy metal forming processes are often chosen based on the specific characteristics of the alloy series and the desired final product. Here’s a general overview of which aluminum alloy series is commonly used for different metal forming processes:

1. Extrusion:

Extrusion: As mentioned earlier, extrusion is used to create aluminum profiles and structural shapes with uniform cross-sections.

Alloy Series: 6000 Series (Aluminum-Magnesium-Silicon Alloys) is frequently used for extrusion due to its excellent formability, machinability, and weldability. These alloys can be easily extruded into complex shapes, making them ideal for applications like frames and structural components.

2. Sheet Metal Forming:

Alloy Series: For sheet metal forming processes like bending, stretching, and stamping, the 1000 Series (Pure Aluminum) and 5000 Series (Aluminum-Magnesium Alloys) are commonly used. They offer good formability and corrosion resistance, making them suitable for automotive body panels, kitchen utensils, and other formed sheet metal products.

3. Casting:

Casting: Molten aluminum is poured into molds to create parts with intricate shapes. Common casting methods include die casting and sand casting.

Alloy Series: Casting processes, such as sand casting and die casting, often use various aluminum alloy series depending on the desired properties. The 3000 Series (Aluminum-Manganese Alloys) and 4000 Series (Aluminum-Silicon Alloys) are common choices for casting applications due to their good castability and corrosion resistance.

4. Forging:

Forging: Aluminum is heated and shaped by applying compressive force. Forging is used to create strong and durable components like automotive parts and aircraft components.

Alloy Series: Forging requires alloys with good mechanical properties and heat-treatability. The 2000 Series (Aluminum-Copper Alloys) and 7000 Series (Aluminum-Zinc Alloys) are suitable for forging applications, as they offer high strength and are heat-treatable for further improvement.

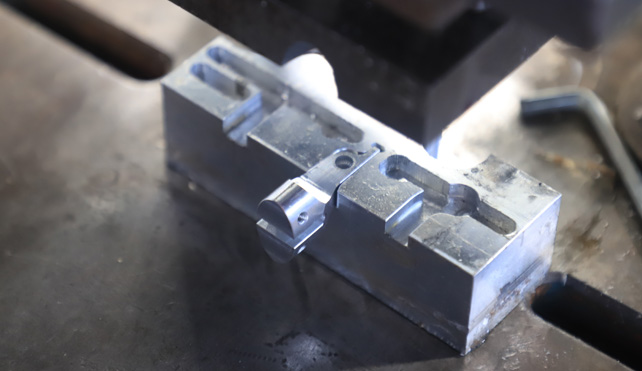

5. CNC Machining:

CNC Machining: Precision machining processes like milling, turning, and drilling are used to shape aluminum components with high accuracy. Suitable for complex geometries.

Alloy Series: When machining aluminum, the 6000 Series and 7000 Series alloys are often preferred. They provide good machinability and can be easily shaped into various components using milling, turning, and drilling processes.

6. Welding:

Welding: Joining aluminum components by melting the material and fusing it together. Various welding techniques like TIG, MIG, and spot welding are used.

Alloy Series: The choice of aluminum alloy for welding depends on the welding method. Generally, the 6000 Series and 7000 Series are suitable for welding processes like TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) due to their good weldability.

7. Stamping: Metal sheets are cut and shaped using dies and punches. Often used for mass-producing parts with consistent shapes.

8. Drawing: Thin-walled aluminum tubes or rods are pulled through a die to reduce their diameter and increase their length.

9. Rolling: Aluminum sheets and plates can be reduced in thickness through rolling processes. This is often used for creating foil or thinner sheets.

The choice of alloy form and metal forming process depends on the specific requirements of the component, including its intended use, desired properties, and manufacturing volume. Each combination offers distinct advantages and limitations in terms of cost, efficiency, and performance.

It’s important to note that the specific alloy within each series can also affect its suitability for different metal forming processes. The selection should consider factors such as the required strength, corrosion resistance, and the intended application of the final product. Additionally, each alloy series can be further customized with specific alloying elements to meet precise performance requirements.

Aluminum Alloy Series Materials Advantages Comparison

Certainly, here’s a comparison of some common aluminum alloy series based on their characteristics:

1. 1000 Series (Pure Aluminum):

Formability: Excellent formability for bending and shaping.

Machinability: Good machining properties.

Weldability: Can be welded using most common methods.

Corrosion Resistance: High corrosion resistance.

Heat Treatment: Not heat-treatable.

Weight: Lightweight.

Applications: Used in chemical equipment, food processing, and general applications where corrosion resistance is essential.

2. 2000 Series (Aluminum-Copper Alloys):

Formability: Good formability.

Machinability: Moderate machinability.

Weldability: Fair weldability.

Corrosion Resistance: Moderate corrosion resistance.

Heat Treatment: Heat-treatable for improved strength.

Weight: Moderate weight.

Applications: Commonly used in aerospace applications due to their high strength-to-weight ratio.

3. 3000 Series (Aluminum-Manganese Alloys):

Formability: Good formability.

Machinability: Good machining properties.

Weldability: Excellent weldability.

Corrosion Resistance: Excellent corrosion resistance.

Heat Treatment: Not heat-treatable.

Weight: Lightweight.

Applications: Used for cooking utensils, heat exchangers, and general applications requiring corrosion resistance.

4. 5000 Series (Aluminum-Magnesium Alloys):

Formability: Good formability.

Machinability: Moderate machinability.

Weldability: Excellent weldability.

Corrosion Resistance: Excellent corrosion resistance.

Heat Treatment: Not heat-treatable.

Weight: Moderate weight.

Applications: Widely used in marine, automotive, and architectural applications due to their corrosion resistance.

5. 6000 Series (Aluminum-Magnesium-Silicon Alloys):

Formability: Good formability.

Machinability: Good machining properties.

Weldability: Good weldability.

Corrosion Resistance: Moderate corrosion resistance.

Heat Treatment: Heat-treatable for improved strength.

Weight: Moderate weight.

Applications: Versatile series used in structural components, extrusions, and a wide range of general applications.

6. 7000 Series (Aluminum-Zinc Alloys):

Formability: Good formability.

Machinability: Moderate machinability.

Weldability: Fair weldability.

Corrosion Resistance: Moderate corrosion resistance.

Heat Treatment: Heat-treatable for high strength.

Weight: Moderate weight.

Applications: Commonly used in aerospace, sporting equipment, and high-strength applications.

The choice of aluminum alloy series depends on the specific requirements of the application, including strength, corrosion resistance, formability, and weight considerations. Each series offers unique properties suited to different industrial and commercial needs.

Aluminum Alloy Series Materials Application

Aluminum alloy series materials find diverse applications across various industries due to their unique properties. Here’s an overview of the applications of different aluminum alloy series:

1. 1000 Series (Pure Aluminum):

Applications: Pure aluminum, with excellent corrosion resistance, is used in applications requiring high electrical conductivity, such as electrical wiring and power transmission lines.

2. 2000 Series (Aluminum-Copper Alloys):

Applications: These alloys are known for their high strength and are used in aerospace applications, including aircraft and aerospace structural components.

3. 3000 Series (Aluminum-Manganese Alloys):

Applications: Aluminum-manganese alloys are often used in cookware, kitchen utensils, and architectural structures due to their good corrosion resistance and formability.

4. 4000 Series (Aluminum-Silicon Alloys):

Applications: These alloys are primarily used in welding applications, such as filler materials for welding aluminum parts.

5. 5000 Series (Aluminum-Magnesium Alloys):

Applications: Widely used in marine and automotive applications due to their combination of strength, corrosion resistance, and formability. They are used for vehicle body panels, boat hulls, and other structures.

6. 6000 Series (Aluminum-Magnesium-Silicon Alloys):

Applications: Versatile alloys suitable for a wide range of applications, including architectural structures, window frames, automotive components, and bicycle frames.

7. 7000 Series (Aluminum-Zinc Alloys):

Applications: Known for their high strength, 7000 Series alloys are used in aerospace applications, bicycle frames, and sporting goods where lightweight, durable materials are essential.

8. 8000 Series (Other Aluminum Alloys):

Applications: This series encompasses a variety of specialty alloys with unique properties. For example, 8000 Series alloys may be used in applications requiring specific characteristics like high strength or electrical conductivity.

9. Cast Aluminum Alloys:

Applications: Cast aluminum alloys find use in a wide range of products, including automotive engine components, cookware, and decorative items. The specific alloy choice depends on the casting method and desired properties.

10. Wrought Aluminum Alloys:

– Applications: Wrought aluminum alloys are used in many structural and decorative applications, such as aircraft parts, architectural elements, and automotive components.

The choice of aluminum alloy series depends on the specific requirements of the application, including factors like strength, corrosion resistance, formability, and weight. Engineers and manufacturers select the most suitable alloy series and alloy within that series to meet the desired performance criteria for their products.

Quick Reference Chart – Choosing an Aluminum Grade

| Formability or Workability | Weldability | CNC Machining | Corrosion Resistance | Heat Treating | Strength | Typical Applications | ||||||||

| Aluminum Alloy 1100 | Excellent | Excellent | Good | Excellent | No | Low | Metal Spinning | |||||||

| Aluminum Alloy 2011 | Good | Poor | Excellent | Poor | Yes | High | General Machining | |||||||

| Aluminum Alloy 2024 | Good | Poor | Fair | Poor | Yes | High | Aerospace Application | |||||||

| Aluminum Alloy 3003 | Excellent | Excellent | Good | Good | No | Medium | Chemical Equipment | |||||||

| Aluminum Alloy 5052 | Good | Good | Fair | Excellent | No | Medium | Marine Applications | |||||||

| Aluminum Alloy 6061 | Good | Good | Good | Excellent | Yes | Medium | Structural Applications | |||||||

| Aluminum Alloy 6063 | Good | Good | Fair | Good | Yes | Medium | Aerospace Applications | |||||||

| Aluminum Alloy 7075 | Poor | Poor | Fair | Average | Yes | High | Aerospace Applications |