First of all, let’s understand what is a 2D drawing of a custom CNC machining part? What is a 3D drawing of a custom CNC machined part?

“D” in 2D and 3D is dimension

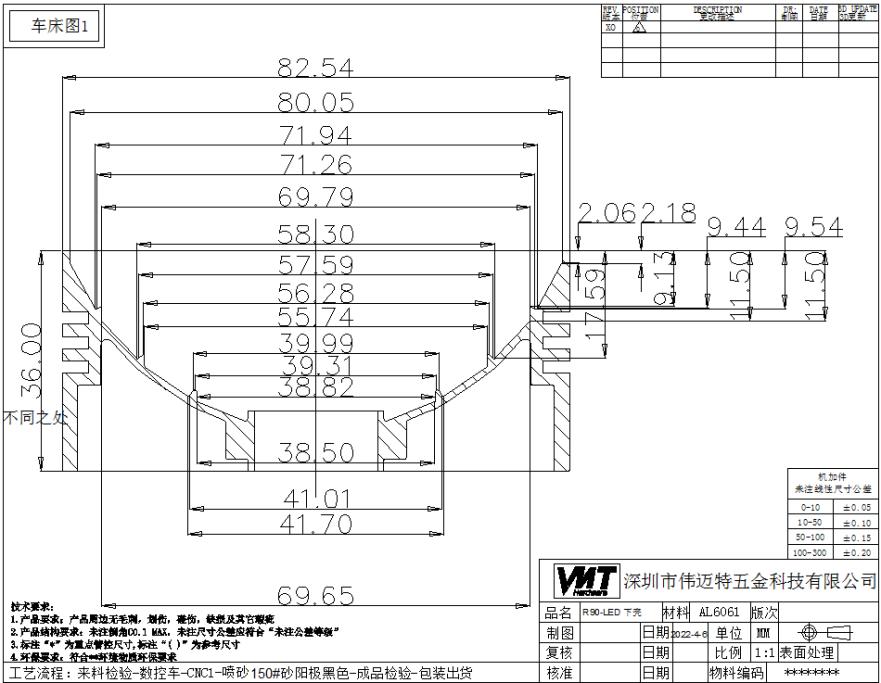

\n2D drawing: 2-dimensional drawing, that is, plane drawing, all drawings are in the X Y plane, including those generally used for industrial custom CNC machining and manufacturing, which is what we call engineering drawings;

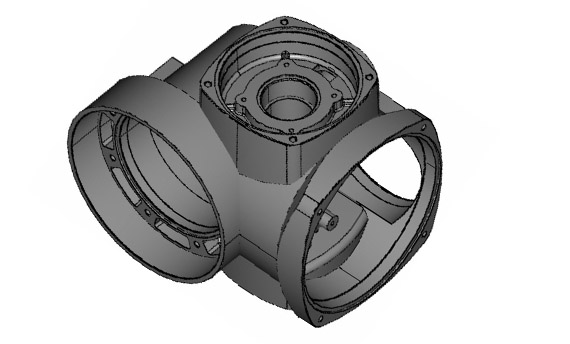

3D graphics: 3D graphics, namely spatial three-dimensional graphics, all graphics are used in modern CNC machining and manufacturing in X Y Z three-dimensional space, and three-dimensional animation also includes three-dimensional graphics.

The 2D drawing format generally includes pictures, PDF, CAD, etc. There are generally technical requirements on the 2D drawing, what material, tolerance level, roughness requirements, what surface treatment and special requirements for CNC machining parts products, whether the hole is a smooth hole or a tooth hole Waiting, knowing these, can clearly quote the accurate quotation of CNC machining parts products. If there is no 2D drawing, a lot of information needs to be confirmed with the customer one by one, which will waste a lot of time to confirm the requirements.

The formats of 3D drawings include STP, XT, IGS, etc. Some 2D dimensions will not be marked completely. If you have 3D drawings, you can open them for measurement and analysis. If you have 3D, you can analyze the weight of CNC machined parts according to 3D. According to the 3D analysis, you can basically know how to customize CNC machining, so that you can report the price more accurately and clearly. 3D drawings can also make DFM analysis and customer communication better.

3D and 2D complement each other. In terms of quotations, almost both 3D and 2D are required. 3D is easier to understand and understand than 2D. Even people who don’t understand drawings can see it. It needs to be understood by the person who sees it in combination with each view. Of course, that’s not to say that 2D isn’t important.

In general, complete 2D and 3D drawing files are provided when quoting. Generally, 3D drawings are provided in STP or XT format, and 2D drawings are provided in CAD or PDF. Special requirements related to products need to be specially explained, so as to be faster, better and more accurate. Quote price.

CNCMF has 12 years of custom CNC machining experience, professional CNC machining of aluminum precision parts, aluminum alloy shell, aluminum alloy cavity and other aluminum parts machining, high-quality surface treatment one-stop service manufacturer, according to the needs of customers for non-standard precision parts machining, combined with cold Hot forging, die casting, extrusion, CNC turning and milling and various difficult surface treatment processes, etc., provide you with high-quality integrated solutions.

If the CNC machining parts you develop have certain requirements for accuracy, and you hope to find a CNC machining manufacturer with good quality and good cooperation, please contact us quickly!