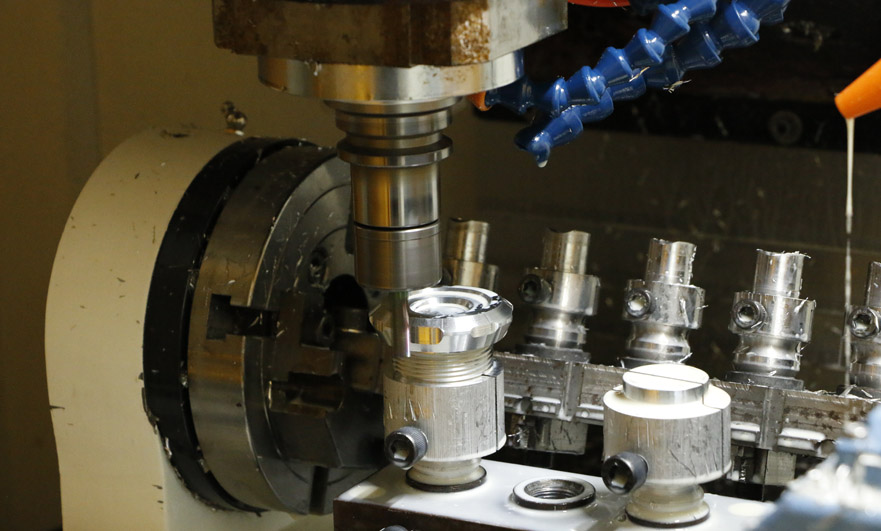

During the machining process of CNC machining center, it is inevitable that the shape of the tool will affect the custom CNC machining parts. The tool and tool holder should be correctly selected according to the machining capacity of the machine tool, the performance of the workpiece material, the machining process, the amount of cutting and other related factors. Therefore, it is very important to observe and judge the working state of the tool. The precision and finish of the custom CNC machined parts will be well reflected when the tool is in the best condition. So where is the main observation, let’s talk to you with the CNCMF CNC machining manufacturer!

1. During the machining process of the new tool of the CNC machining center, the phenomenon of turning back occurs, and the machining is very laborious. What parameters need to be adjusted at this time?

The reason why CNC machining is very laborious is that the power and torque of the spindle cannot withstand the current cutting amount. The reasonable approach is to re-make the path and reduce the depth of the knife, the depth of the slot, and the amount of trimming. If the overall CNC machining time is less than 30 minutes, the cutting state can also be improved by adjusting the cutting speed.

2. What is the Function of Cutting Fluid in CNC Machining Center?

Pay attention to adding cooling oil in metal CNC machining. The function of the cooling system is to take away the cutting heat and flying chips and lubricate the machining. Coolant removes the cutting heat, reducing heat transfer to the tool and motor, increasing their service life. Take the flying chips away to avoid the phenomenon of secondary cutting. Lubrication can reduce cutting forces and make machining more stable. In copper processing, the selection of oily cutting fluid can improve the surface quality of custom CNC machined parts.

3. What are the stages of tool wear in CNC machining centers?

The wear of the tool is divided into three stages: initial wear, normal wear, and sharp wear. In the initial wear stage, the main cause of tool wear is that the temperature of the tool is low and does not reach the optimum cutting temperature. At this time, the wear of the tool is mainly abrasive wear, which has a great impact on the tool and can easily lead to tool breakage. Knife. This stage is a very dangerous stage, and if not handled properly, it may directly lead to tool breakage and failure.

When the tool passes the initial wear period, the cutting temperature of the tool reaches a certain value, which is the main wear is diffusion wear, and its role is mainly to cause local spalling. Therefore, the wear is relatively small and relatively slow. When the wear reaches a certain level, the tool fails and enters a period of rapid wear.

4. Why do CNC Machining Center Tools Need to be Run-in and How to Run-in?

We mentioned above that the tool is easy to break in the initial wear stage. In order to avoid the phenomenon of chipping, we must run the tool. The cutting temperature of the tool is gradually increased to a reasonable temperature. Validated experimentally, comparisons made using the same machining parameters. It can be seen that after running in, the tool life has increased by more than 2 times.

The method of running-in is to reduce the feed rate by half while maintaining a reasonable spindle speed, and the CNC machining time is about 5 to 10 minutes. Take a small value when CNC machining soft materials, and take a large value when machining hard metals.

5. How to Judge the Serious Grinding of CNC Machining Center Tools?

The method for judging severe tool wear is:

1) Listening to the sound of CNC machining, there is a harsh cry;

2) Listening to the sound of the main shaft, the main shaft has obvious stagnation phenomenon;

3) I feel that the vibration increases during CNC machining, and the machine tool spindle has obvious vibration;

4) Looking at the processing effect, the knife pattern on the bottom surface processed by CNC is sometimes good or bad (if it is like this at the beginning, it means that the depth of the knife is too deep).

6. When Should the Knife be Changed?

We should change the tool around 2/3 of the tool life limit. For example, the tool is severely worn in 60 minutes. In the next CNC machining, the tool should be changed at 40 minutes, and the habit of changing the tool should be developed regularly.

7. Can the Severely Worn CNC Machining Center Tool Continue to be Processed?

After severe tool wear, the cutting force can be increased to 3 times normal. The cutting force has a great influence on the service life of the spindle electrode. The service life of the spindle motor and the force are inversely proportional to the third power. For example, when the cutting force is increased by 3 times, machining for 10 minutes is equivalent to using the spindle for 10*33=270 minutes under normal conditions.

8. How to Determine the Protruding Length of the CNC Machining Center Tool During Roughing?

The shorter the extension of the tool, the better. However, in the actual CNC machining, if it is too short, the length of the tool should be adjusted frequently, which will affect the machining efficiency too much. So how to control the protruding length of the tool in actual processing? The principle is this: a 3-diameter shank can be processed normally with a 5mm extension. The φ4 diameter shank extends 7mm and can be processed normally. The φ6 diameter shank extends 10mm and can be processed normally. Try to get below these values when you apply the knife. If the length of the upper knife is greater than the above value, try to control the depth of processing when the tool is worn. This is a bit difficult to grasp and requires more exercise.

9. How to Deal with the Sudden Broken Tool During CNC Machining?

1) Stop processing and check the current serial number of processing.

2) Check the broken tool to see if there is a broken tool body, and if so, take it out.

3) Analyze the reasons for the broken tool, this is the most important, why is the tool broken? If we want to analyze, we need to analyze the various factors that affect the processing mentioned above. But the reason for the broken knife is that the force on the knife suddenly increased. Either the path is wrong, or the tool shakes too much, or the material has a hard block, or the spindle motor rotates incorrectly.

4) After analysis, replace the tool for processing. If the path is not replaced, the original serial number should be processed by a serial number in advance. At this time, it is necessary to pay attention to reducing the feed speed. One is that the broken tool is hardened seriously, and the other is that the tool must be run-in.

The above is the summary of the CNCMF CNC machining manufacturers on the problems encountered when using CNC machining tools. If you have any questions, you can contact us at any time.