The electronics industry emerged in the 20th century. In this day and age, it is one of the largest industries in the world. This industry produces a wide variety of electrical appliances and equipment such as radios, computers, televisions, stereos, semiconductors, transistors, integrated circuits, and more.

Many electronic devices and their components are manufactured using CNC machining. As the electronics industry needs a technology that offers cost-effective mass production, high precision, durability and excellent machining accuracy. Some electronic components or devices are critical to errors and they require ultra-precision. All these demanding properties can be achieved using CNC machining technology.

CNC machining machines can process a wide variety of materials, whether conductive or non-conductive metals or plastics. Another advantage of using CNC machining is that it can produce the smallest semiconductors with extremely high precision. Any small or large CNC machined part of any geometric complexity can also be CNC machined.

The superior reliability offered by CNC processes makes it the first choice for electronics manufacturers. It is used to create small and large assembly production and prototyping of multiple components. Sometimes tight tolerances are required to manufacture parts. CNC machining also provides products with high tolerances.

Another advantage of using CNC machining is that it enables mass production in a short period of time as there is no tooling stage prior to production. Using other technologies such as 3D printing or die casting does not serve the purpose as effectively as CNC technology. Because the CNC machining process does not have quality restrictions. In the case of design modifications, then only the CAD design needs to be modified, making minor changes or changing the entire design.

In this article, we will detail how CNC machining is commonly used in the electronics industry. What are the benefits of using this technology? Some important CNC machining components will also be discussed using it to manufacture.

The Benefits of CNC Machining in the Electronics Industry

The electronics industry benefits greatly from CNC machining. Some of them are discussed below

Manufacturing of Ultra High Precision CNC Machining Parts

Electronic CNC machined parts require high precision. Otherwise, inaccuracies in production can be critical. This is the main factor that makes CNC machining technology superior to other manufacturing technologies. Since all processes are automated, there is little human intervention. This brings precision to the process.

Faster Batch CNC Machining Production

In CNC machining, creating a part only takes a few steps. CAD designs are first created and then converted into digital instructions in the form of CAM code. The next machine is set up, and finally, the machinist will be ready to perform the machining action. Once all these steps are done, creating any number of parts is just a matter of the necessary time spent operating the machine. In this way, we can easily perform batch CNC machining production at a faster rate.

Cost-Effective CNC Machined Part Manufacturing

One of the main advantages of CNC machining electronic parts is that it offers prototyping and batch CNC machining production at very reasonable prices. If a prototype needs to be built to test a new design, it can be done easily and at a lower price. In addition to this, the technology reduces labor costs and the possibility of errors that can lead to schedule delays and material scrap.

Superior CNC Machining Accuracy and Efficiency

Since the entire CNC machining process is controlled by digital instructions of computer commands and requires little human assistance. This automation capability is why CNC machining provides excellent machining accuracy and efficiency. This is extremely important in the electronics industry.

Manufacture of Electronic Parts Using CNC Machining

For many of the obvious reasons mentioned above, CNC technology is widely used by the electronics industry. Parts made by electronics manufacturers, some of the important ones are discussed below:

Semiconductor

The birth of the semiconductor brought a revolution to the electronics industry. The MOSFET (Metal Oxide Semiconductor Field Effect Transistor) or MOS transistor is considered the most widely manufactured device in human history. Semiconductor materials such as silicon and aluminum nitride have huge uses in semiconductor manufacturing. They are machined with precision CNC technology.

These tiny semiconductor devices require tight tolerances and durability, which can be easily achieved with CNC machining. Semiconductor components manufactured using CNC machining processes include land stencils, flexible circuit stiffeners, wafer chucks, and more.

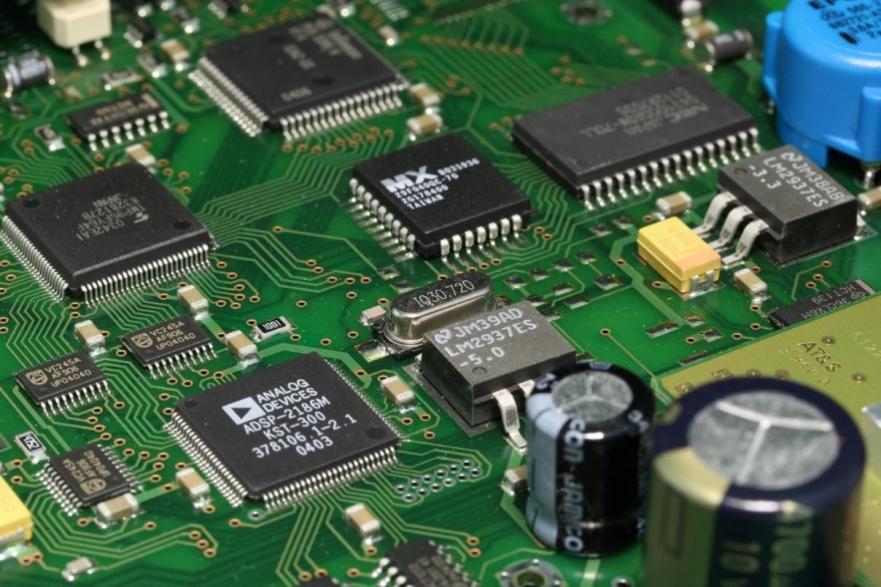

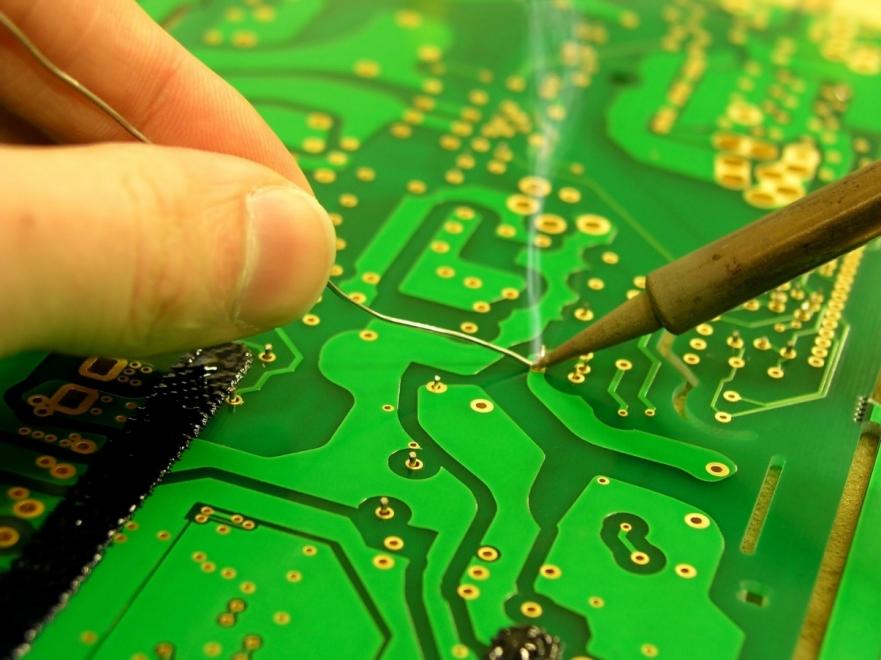

Printed Circuit Board (PCB)

A PCB is a printed circuit board that mechanically supports and electrically connects different electronic components. It uses many conductive tracks, pads and other features. These are etched onto a non-conductive substrate. Etching plays an important role in PCB creation.

Most PCBs are manufactured through etching processes that involve hazardous chemicals. This may not be suitable for many entities such as offices, homes, and can be extremely detrimental to disruptive events.

But manufacturing printed circuit boards with CNC machining does not involve the use of hazardous chemicals. This makes the CNC process a more viable and safer option. It makes it easy to develop functional PCBs that are safer to use in vulnerable entities.

CNC machined PCBs have many benefits, such as elimination of harmful chemicals, cheaper, shorter manufacturing times, and greater durability.

Heat Sink

Heat sinks are passive heat exchangers used to prevent overheating of electronic equipment. These are installed in many devices to dissipate heat so that the device can function properly. It absorbs the heat generated in electronic CNC machined parts and dissipates it.

CNC machined heat sinks are very precise and efficient in their cooling mechanism. The atypical fin pattern created provides an upper edge that prevents overheating. Commonly used materials for radiators are stainless steel, aluminum or copper alloys.

Precision machined heat sinks offer several advantages, such as manufacturing with fin patterns, multiple material options, faster batch CNC machining production, and more.

Connectors and Receptacles

CNC machining can also be used to manufacture different connectors and sockets for different purposes. For example, connect two electronic devices, such as electronic musical instruments, to an amplifier to amplify the sound. So to connect these two devices, we need connectors and sockets made of metal to establish the electrical connection between them.

Because these connectors and sockets require tight tolerances and high precision to effectively connect two devices. When establishing a connection, the tiniest mistake can lead to a breakup. Therefore, CNC machining is the first choice. The material commonly used to manufacture such devices is copper alloy. This heading includes electronic components such as contacts, bushings, pins, etc.

The advantages of precision CNC machined connectors and sockets are tight tolerances, high precision, durability, and variety of materials.

Electronics Casings and Enclosures

CNC machining technology enables the manufacture of semiconductors and printed circuit boards. But on the other hand, it can also be used to manufacture housings and enclosures for different electronic devices that are used as housings or enclosures.

Using precision CNC machining techniques to manufacture these electronic housings and enclosures has many advantages over using other techniques such as die casting, 3D printing, etc. Because of their extreme precision and good surface finish. Many electronic devices, such as computers, cameras, CROs (cathode ray oscilloscopes), require rugged housings. Keep the internal hardware safe.

The advantages of CNC machined castings and housings are robustness, wide choice of materials, excellent surface finish, durability, and more.

In Conclusion

Electronic devices are used in almost all electronic devices. Inaccuracies in any device can be critical and can have catastrophic consequences. Therefore, most electronic devices are manufactured using CNC machining technology. This ensures the production of ultra-precise CNC machined parts.

There are many other CNC machining manufacturing techniques, but none are preferred over precision CNC machining. Because CNC machined electronic parts are extremely precise and durable. This is important in the electronics industry.

If you are looking for a trusted CNC machining manufacturer, you are in the right place. We are one of the most advanced CNC machining workshops in China. We have earned the trust of more than 500 valuable clients around the world, with business editors in 62 countries around the world. If you need custom CNC machined parts, prototype CNC machining services or have questions about your CNC machined designs. You just need to contact us. Our team will provide you with one-stop service for CNC machining.

CNCMF has a team of designers, engineers and technicians with more than 10 years of experience. They are always ready to provide you with high precision and durable CNC machining services with outstanding efficiency and CNC machining accuracy.