When programming for CNC machining, the programmer must determine the amount of cut in each process.

When choosing cutting parameters, we must fully consider the various factors that affect cutting, choose the correct cutting conditions, and reasonably determine the cutting parameters in order to effectively improve the quality and production capacity of CNC machined parts.

Factors affecting cutting conditions are: the rigidity of machine tools, fixtures, tools and workpieces; cutting speed, depth of cut, cutting feed rate; workpiece accuracy and surface roughness; tool life and maximum productivity; types of cutting fluids and cooling methods; CNC The hardness and heat treatment state of the material of the processed parts; the number of workpieces; the service life of the CNC machining machine tool.

Among the above factors, cutting speed, depth of cut and cutting feed rate are the main influencing factors.

1. Pay attention to the degree of matching between the tool material and the material of the CNC machined parts.

(1) Tool material.

Different CNC machining tool materials have different maximum cutting speeds. The high-temperature cutting speed of high-speed steel tools is less than 50m/min, the high-temperature cutting speed of cemented carbide tools can reach more than 100m/min, and the high-temperature cutting speed of ceramic tools can be as high as 1000 m/min.

(2) Materials for CNC machining parts.

The hardness of the material of the CNC machined parts will affect the cutting speed of the tool. When the same tool is processing hard materials, the cutting speed should be reduced, and when processing softer materials, the cutting speed can be increased.

⑶ Tool life for CNC machining.

If the tool life (life) is long, a lower cutting speed should be used. Conversely, higher cutting speeds can be used.

2. Cutting depth and feed

The cutting depth and cutting amount are large, the cutting resistance is also large, and the cutting heat will increase, so the cutting speed should be reduced

3. The shape of the CNC machining tool

The shape of the tool, the size of the angle, and the sharpness of the cutting edge will affect the choice of cutting speed.

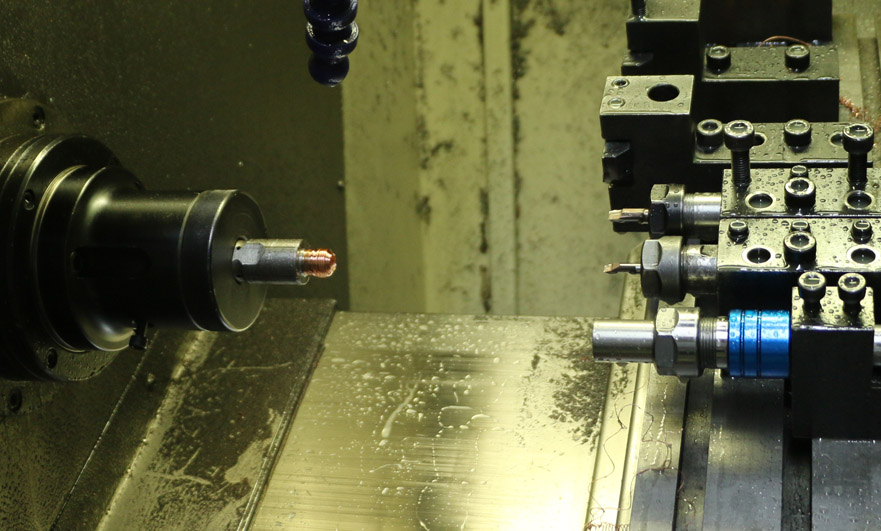

4. Selection of cutting fluid

The two major functions of cutting fluid for CNC machining centers are lubrication and cooling.

Note: Use coolant. A machine with good rigidity and high precision can increase the cutting speed; otherwise, the cutting speed needs to be reduced. Among the above-mentioned factors affecting cutting speed, the influence of CNC machining tool materials is the most important.

The depth of cut is mainly limited by the rigidity of the machine tool. The cutting depth can be increased if the rigidity of the CNC machine tool allows. If it is not limited by the machining accuracy, the cutting depth can be made equal to the CNC machining allowance of the part.

All in all, the cutting volume of the process is a factor that must be considered when programming the CNC machining center. When selecting the cutting amount, various factors that affect the cutting must be fully considered. Reasonable cutting conditions and cutting volume can effectively improve the quality and production quantity of CNC machined parts. Then there are many factors that affect the cutting conditions.

Take the CNC machining center as an example. The configuration of equipment, the selected tools, the material, hardness, and rigidity of the workpiece; cutting type, cooling method; cutting speed, depth and feed rate; factors such as precise determination of the cutting amount and feed rate cannot be ignored.