CNC index-controlled machine tools are programmed and operated by CNC machining language, generally G code. The CNC machining G code language informs the CNC machine tool which Cartesian coordinates to use for the machining CNC blade, and controls the CNC blade’s cutting speed and spindle bearing speed ratio, as well as its special tool changer, coolant and other functions. What is the development status of the manufacturing industry in CNC machining? With the development of science and technology and the advancement of productive forces, great changes have taken place in manufacturing technology, and the product structure has become more and more complex, streamlined and rational. The precision and efficiency of its processing requirements continue to improve, and the technology of the CNC machining industry also continues to improve.

Manufacturing development status of CNC machining center:

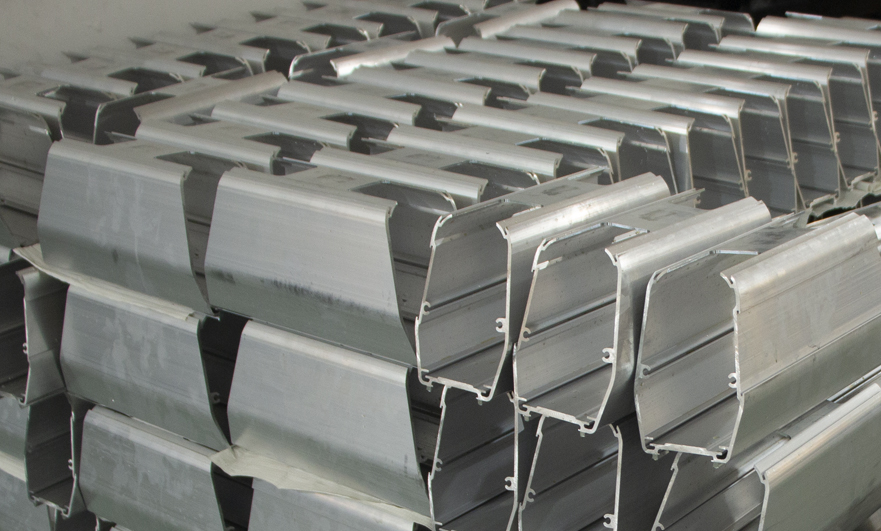

In the past, in the CNC machining and manufacturing products, precision CNC machining parts and small batch CNC machining parts accounted for the majority. Due to the variety of such products and high precision requirements, ordinary machine tools were generally selected for processing, but it was difficult to ensure product quality. In order to solve the production efficiency and high precision requirements of mass production, high-precision and high-automation CNC machining machines are generally used. CNC machining machine is composed of input and output structure, computer numerical control structure, servo system and controlled system. CNC machining machine tools can be divided into: ordinary CNC machining machine tools and CNC machining centers. Ordinary CNC machining machine tools cannot achieve full automation, and tool replacement and CNC machining parts clamping still need to be done manually.

The CNC machining center is a CNC machining machine with its own tool library and automatic tool change. After one clamping, it can realize continuous processing of multiple processes. CNC multi-axis machining center improves the accuracy of CNC machining parts and CNC machining efficiency by reducing errors.

CNC machining machine tools can solve single-piece small batch CNC machining production and automatic machining of complex CNC machining parts. CNC machining is an advanced processing technology in the manufacturing industry. It has brought long-term changes to the product structure and production methods of the manufacturing industry, enabling the manufacturing industry to realize automation and integrated production. So how to choose a small batch CNC machining factory?

Small batch CNC machining is a part of machining. There are two main processing forms: one is to fix the turning tool to process the unformed workpiece during rotation; the other is to fix the workpiece, and through the high-speed rotation of the workpiece, the turning The lateral and longitudinal movement of the tool (tool holder) performs precision machining. What are the criteria for choosing a high-quality small-batch CNC machining factory?

1. Small batch CNC machining should have high-precision CNC machining equipment, and among CNC machining equipment, three-axis CNC machining is suitable for processing simple products, four-axis five-axis can process multi-curved products, but four-axis five-axis CNC machining The cost is higher than the triaxial.

2. It is not enough to have CNC machining equipment alone. Small batch CNC machining also needs to be equipped with complete testing equipment. The testing dimensions include: calipers, micrometers, altimeters, two-dimensional, three-coordinate testing, etc.; Tester; spectrometer for detecting material composition; needle gauge and plug gauge for detecting aperture and thread, as well as ISO9001, IATF16949 certificates, etc.

3. With good CNC machining factory management and service concept, the development of new products will inevitably involve design modifications and small detail modifications, all of which require the CNC machining factory to cooperate closely with you in order to process good products and allow customers to spend the same money. different quality.

In addition, the choice of manufacturers for small batch CNC machining should be considered for the price. There are not many CNC machining products in small batches, but every time you need a little bit, then the price will be taken into account when choosing a CNC machining manufacturer, because everyone knows that if you only CNC process one part, the CNC machining manufacturer’s The price will be much higher relative to small batches, so small batches of CNC machined parts can make money for manufacturers and allow production to run normally.

The above are the status of CNC machining in the manufacturing industry and the three criteria for selecting small batch CNC machining factory. I believe that after reading it, you should know how to choose high-quality CNC machining manufacturers to provide the pass rate of CNC machining parts and enjoy high-quality CNC machining services.

CNCMF 13 years custom precision CNC machining parts, metal, plastic prototype machining factory. Its business covers 62 countries around the world, covering military, medical, semiconductor, automotive and other fields. 40+ materials and 15+ surface finish options with free service design, project reviews and DFM analysis. To ensure the quality of parts, we passed the ISO9001 quality system and SGS on-site factory audit in 2015. No matter how complex your part structure is, or your product encounters technical problems, we can provide you with professional service! Save you 15% time cost and communication cost!