As we all know, medical accessories have different requirements on the material and precision of products. Large medical equipment companies will also consider how to choose high-quality CNC machining suppliers, online collection, and many manufacturers seem to be similar. However, CNC machining companies with integrity and comprehensive strength are stretched thin.

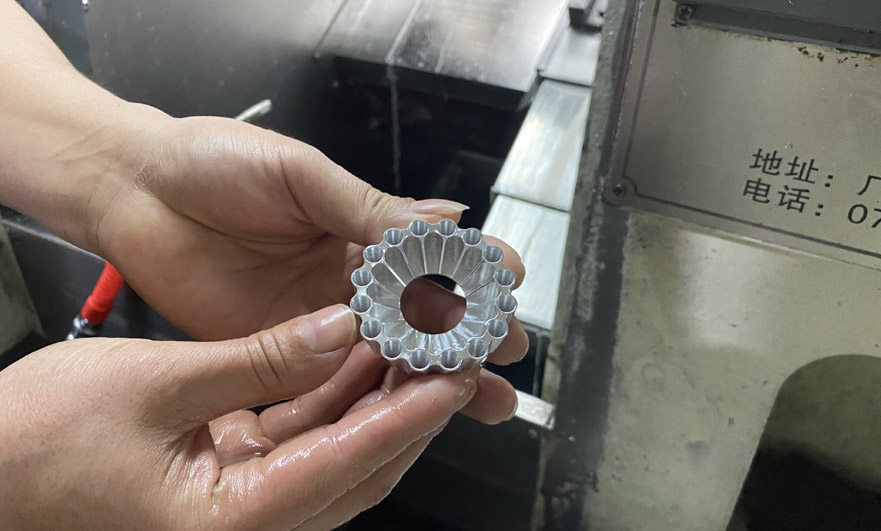

The healthcare industry is an industry known for its rare chance of going wrong. The same rules apply to the production of medical CNC machined parts. This is because human lives are involved in this industry and few mistakes can lead to fatal health problems or even death. Therefore, in the production of medical CNC machined parts, the machining process must be able to accommodate tight tolerances and high-precision measurements.

Manufacture qualification of medical CNC machining parts

Machining medical parts for the medical industry is different from CNC machining parts for other industries. Most common metal CNC machined parts must meet ISO 9001 quality management requirements, while medical components must meet further standards.

According to the International Standards Organization, companies involved in the design, development, production, storage, distribution, installation or repair of medical components must “have the ability to provide medical equipment and related services that consistently meet customer and applicable regulatory requirements.”

For your medical CNC machined parts to be licensed, they must pass the following eligibility criteria:

ISO 13485: This is a qualification standard specific to the medical industry. It extends the more detailed details of the ISO 9001 standard related to the medical industry, emphasizing the specification of the production process. It regulates production stages such as process validation, risk management and quality control. Adhering to this standard makes it easier for any company to bring its products to the international market.

In addition, other additional eligibility criteria for assessing the quality of medical precision CNC machined parts include:

ISO 9001: This is a general standard for quality control manufacturing management. However, it is not specific to any industry. This means that the ISO 9001 standard controls virtually every production process. It helps minimize CNC machining costs and promotes company growth while establishing adherence to established standards.

ISO 5001: This quality standard is based solely on energy management. It provides a basis for medical CNC machining parts manufacturers to improve energy efficiency. In this way, the production cost can be further reduced.

ISO 14001: This is a similar but broader quality standard than ISO 5001. It also highlights energy sustainability in partnership with ISO 5001; medical CNC machined components manufacturers can reduce energy consumption and waste production. Any company with this quality standard will surely incorporate 50001 ISO into its business.

Suppliers are part of the open system of the supply chain, and the choice of suppliers is also affected by various economic, political and other factors.

Quality factor

Quality is the survival of the supply chain. The value of a product depends on the quality of the product. It determines the quality of the final consumer product and affects the market competitiveness and market share of the product. Therefore, quality is an important factor in choosing a CNC machining supplier.

Price factor

The low price means that the company can reduce production and operation costs, which has a significant effect on improving the company’s competitiveness and increasing profits. This is an important factor in choosing a CNC machining supplier. However, a CNC machining manufacturer with a low price is not necessarily the most suitable CNC machining supplier, but factors such as product quality, delivery time and transportation costs are also considered.

The machining precision of medical equipment is high, so CNC machining is suitable for machining high-precision CNC machining parts. However, if the right people aren’t handling the job, the process used doesn’t matter.