The rapid development of mechanical CNC machining and manufacturing has higher requirements for the accuracy of equipment parts, and the demand for high-precision custom CNC machining parts requires CNC machining parts manufacturers to improve the processing technology.

CNC machining process is the process of machining parts according to drawings. There is more than one machining process. For complex custom CNC machining parts, a variety of CNC machining processes will be used to obtain the final shape of CNC machining parts. This requires CNC machining manufacturers and processing personnel to analyze the advantages and disadvantages of each CNC machining process, and comprehensively select a suitable CNC machining process. Make the precision of custom CNC machined parts meet customer requirements, increase the service life of parts, and improve the yield of CNC machined parts.

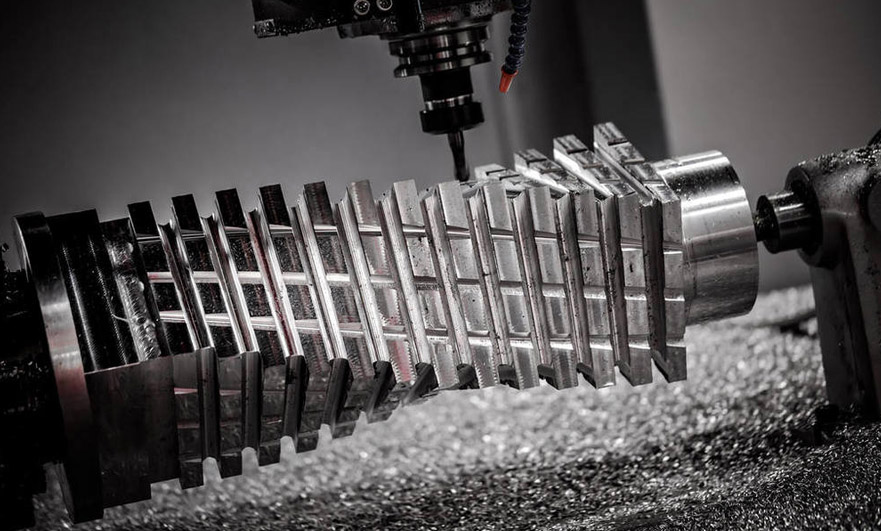

Lathe tools for custom CNC machined parts

Reasons Affecting the Accuracy of Custom CNC Machining Parts

1. In the actual CNC machining work, high-precision CNC machining parts also have high requirements for the installation of tools and fixture devices.

2. Customized CNC machining parts must be inseparable from CNC machining machine equipment. The processing of raw materials is controlled by CNC machining machine tools. Continuous use for a long time will always affect the performance of CNC machining machine tools, which in turn affects the accuracy of CNC machining parts and affects customization. One of the reasons for the accuracy of CNC machined parts must be the error of CNC machine tool guide rails. This requires the CNC machining factory to maintain the parts of various parts of the CNC machining machine in a timely manner, especially the parts that are frequently used and easy to wear.

Custom CNC Machining Parts Lathe Maintenance

3. Geometric parameter error. Before customizing CNC machining parts, it is necessary to measure the CNC machining machine. The systematic error, environmental error or human error of the measuring tool will generate geometric errors and affect the accuracy of CNC machining parts. Part of the reason is because of CNC machining The use of the machine tool for too long has led to the aging of the machine tool. Although there is timely maintenance, parts need to be replaced when necessary.

4. Force deformation, in the process of customizing CNC machining parts, when the tool of the equipment cuts the raw material, due to the action of external force, the original force balance state of the parts is broken, resulting in uneven force on the CNC machining parts and mechanical deformation. As a result, the precision of CNC machined parts is reduced.

Solutions to Accuracy Problems for Custom CNC Machined Parts

1. DFM analyzes the factors that may reduce the accuracy of CNC machined parts in the process of CNC machining, comprehensively uses professional skills, establishes a complete set of CNC machining process rules and countermeasures, and forms an internal CNC machining system.

2. The CNC machining process is the main part of custom CNC machining parts. The staff needs to strictly control the operation status of the equipment, and at the same time, carefully and responsibly verify the eligibility of the dimensions of the CNC machining parts. When encountering factors that affect the accuracy of the parts, It is necessary to analyze the cause of the error, and then adjust the equipment parameters in real time according to the CNC machining process rules set in the first item and the coping methods indicated above, so as to ensure the product quality and pass rate while improving the production efficiency of CNC machining.