During this time, we received an inquiry from a Japanese customer for aluminum precision CNC machining parts on Google. The product is an aluminum part with a diameter of 170MM; the surface needs to be like an apple shell with an accuracy of 0.02mm to ensure the parallelism of the finished product. At 0.03mm, the same roundness is 0.01mm. For CNC machining of aluminum parts, this precision is high within the industry standard, and more than 95% of factories cannot do it!

CNCMF has 12 years of experience in professional aluminum alloy precision CNC machining parts, turning and milling CNC machining, 5-axis CNC machining parts, rich engineering experience, complete equipment, and strict quality control process. If you encounter problems with precision CNC machining parts, please contact us.

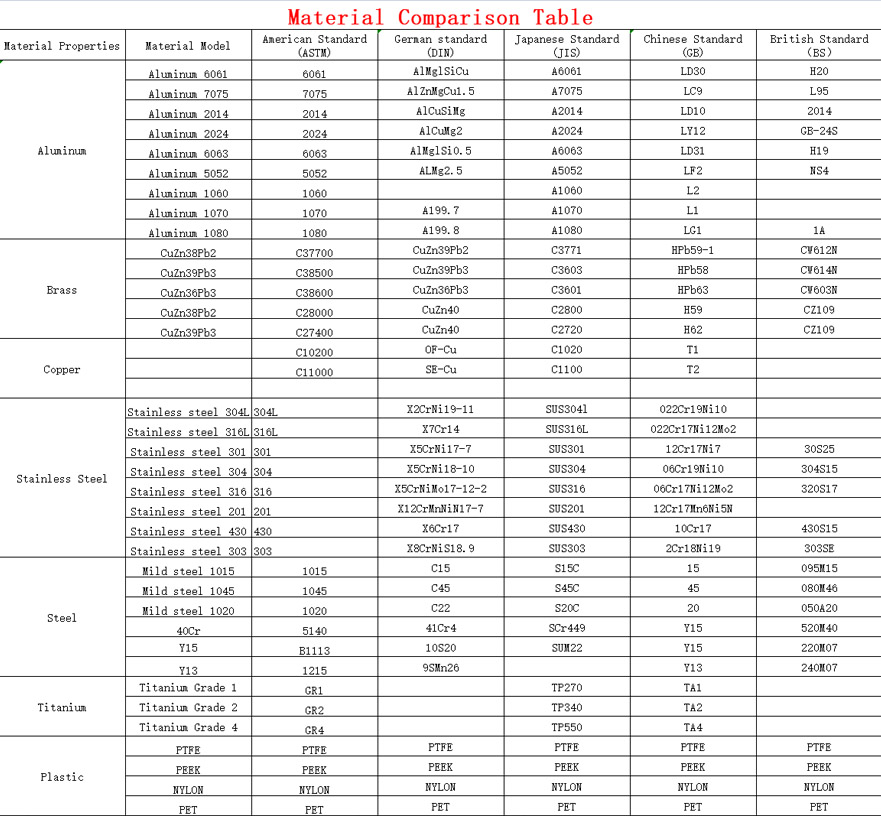

Because of the structural characteristics of the CNC machined parts of the customer, in order to reduce the cost, we used the national standard 6061 aluminum tube for processing. During the first turning and milling CNC machining process, the product has not been able to meet the drawing requirements. After many adjustments and replacement of materials, it was finally found that the pipe had a stress deformation during the CNC machining process.

In order to ensure the customer’s delivery time, when the national standard 6061 aluminum alloy pipe material could not meet the requirements of the drawings, it was replaced with solid material at the first time. After the first experience of 6061 aluminum alloy pipe material, when we measured the first piece with the three-dimensional inspection instrument, the size was still out of tolerance by 0.002mm;

At this time, we realized that the material stress still exists. The normal process to relieve stress is to leave the product in its natural state for a period of time; this will affect our delivery time. The size of CNC machined parts cannot meet the requirements of the drawings.

Solving the dimensional problem of precision CNC machining parts is another difficulty that we have encountered. How does CNC machining solve the cumulative dimensional tolerance and clamping dimensional tolerance? During the SPC analysis of CNC machining, it was found that the size of the product was unstable. We successively ruled out the unstable factors caused by the production process and fixture, and finally found that the dimensional tolerance of the positioning reference was too large, resulting in the clamping of each precision CNC machining part. Tolerance is too large. After improving the fixture to replace the positioning point, the abnormality of the instability of precision CNC machining parts has been solved.