When the parts are machined, there will always be burrs. Burr is a common problem in CNC machining. Burr will affect the quality of your parts and increase the surface roughness. Therefore, deburring is an indispensable process in mechanical processing. Due to different materials and thicknesses, the machining methods we choose are also different.

How to deburr correctly, we should start with “What is a glitch?” Then look for a suitable deburring method.

What is a glitch?

Burrs are small metal thorns (which may be needle-like or flake-like) produced on the edge of the machined surface after machining.

There are many deburring methods. Common deburring methods include manual deburring, high-pressure water spray deburring, grinding deburring, chemical deburring, electrochemical deburring, and so on. However, it is difficult to achieve the desired effect when the inner diameter pores are deburred in the processing positions of metal parts with complex shapes. It is not an easy task to complete the deburring of precision parts without affecting the material characteristics. Electrochemistry can not only remove burrs, but also achieve the precision and smoothness of the workpiece.

What is electrochemical deburring?

Electrochemical deburring mainly applies the principle of viscous liquid film, and uses the anodic dissolution process of metal in a certain electrolyte to achieve the process method of deburring.

Principles of Electrochemical Puncture

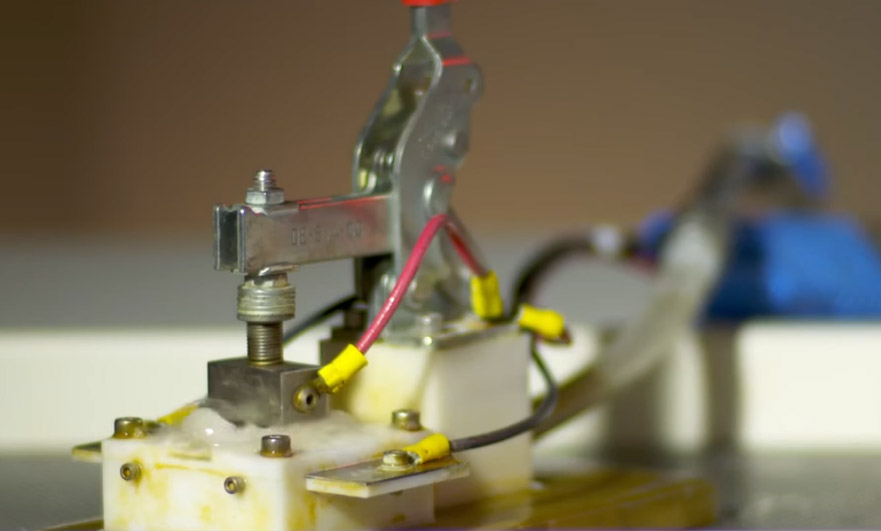

The part is the anode and the tool electrode is the cathode. When the electrolyte is passed between the burr of the part and the specially designed tool, when the electrode is crowded, the electrolysis voltage is passed for a short time. Make the part of the burr or edge on the part the most concentrated current and increase the current density. The burrs are removed quickly, and the edges and corners are also rounded.

Electrochemical Depuncture Method

Electrolytic chemistry is conductive and is not suitable for deburring non-metal parts. In the process of electrochemical deburring, the part and the tool electrode are relatively fixed, which belongs to the electrochemical machining method of the fixed tool cathode.

In order to prevent the metal contact between the anode (workpiece) and the cathode (electrode) from being short-circuited and causing damage to the electrodes and parts. Therefore, the size and direction of the burrs on the parts must be specified as follows:

1. The length of the burr parallel to the electrode is not more than 0.8mm;

2. The maximum burr thickness is 0.15mm;

3. For parts, the main and auxiliary cross holes must be manually hinged;

4. Make the direction of the burr parallel to the axis of the hole to avoid and reduce the short circuit phenomenon of the electrode and reduce the wear of the electrode insulator layer;

5. The material and position of the processed parts must be consistent with the electrodes used, and be “special-specific”, otherwise the parts and electrodes will be damaged, and the processing power supply will be damaged, so we must attach great importance to it;

6. The chips and dirt adsorbed on the parts will also cause short-circuit failures, processing defects and poor electrical contacts during processing. Therefore, the parts must be cleaned before they can be processed;

7. After the workpiece is deburred, the surface of the part has electrolyte adhered to it, and it must be cleaned and rust-proofed.

Application of Electrochemical Puncture

Electrochemical deburring is mainly suitable for parts that are small in size, difficult to remove burrs by manual or mechanical methods, and have more complex shapes. It is especially suitable for gears, worm gears, stamping parts with complex shapes, instrument parts, and bearing cages.

Electrochemical deburring is the best for parts that need surface treatment after machining, because the combined processing technology of deburring and surface treatment can be realized, which not only saves time and effort, but also helps improve the quality of surface treatment.

While deburring, the entire outer surface of the part will also be electrochemically polished. After surface treatment, the oxide part will be darker and brighter, the phosphating part will get a finer phosphate film, and the electroplating part will get smoother Plating.

Summarize

The electrochemical deburring method saves costs, but the electrolyte is also corrosive. After the CNC machining is completed, it needs to be cleaned and rust-proofed to avoid damage to the parts.