Aluminum CNC machining parts have the advantages of high efficiency and high precision. According to the structural characteristics and use characteristics of various CNC machine tools, according to the characteristics and requirements of aluminum CNC machining parts, a reasonable processing process roadmap is formulated.

The realization of high efficiency and high precision of aluminum CNC machining parts is the result of the complementary and comprehensive effects of various process conditions. In addition to hardware factors such as machine tools, tools, fixtures, attachments and even cutting fluids, these process conditions also include software factors such as the selection of cutting parameters, process arrangement, structural features of parts, programming system functions, and CNC machining costs.

In the process of aluminum CNC machining parts, different methods should be used for processing according to the different structural characteristics of the parts, such as blank acquisition, process design, clamping method, programming method, etc.

CNCMF is here today to share with you the main points of different types of aluminum CNC machining parts, hoping to help you.

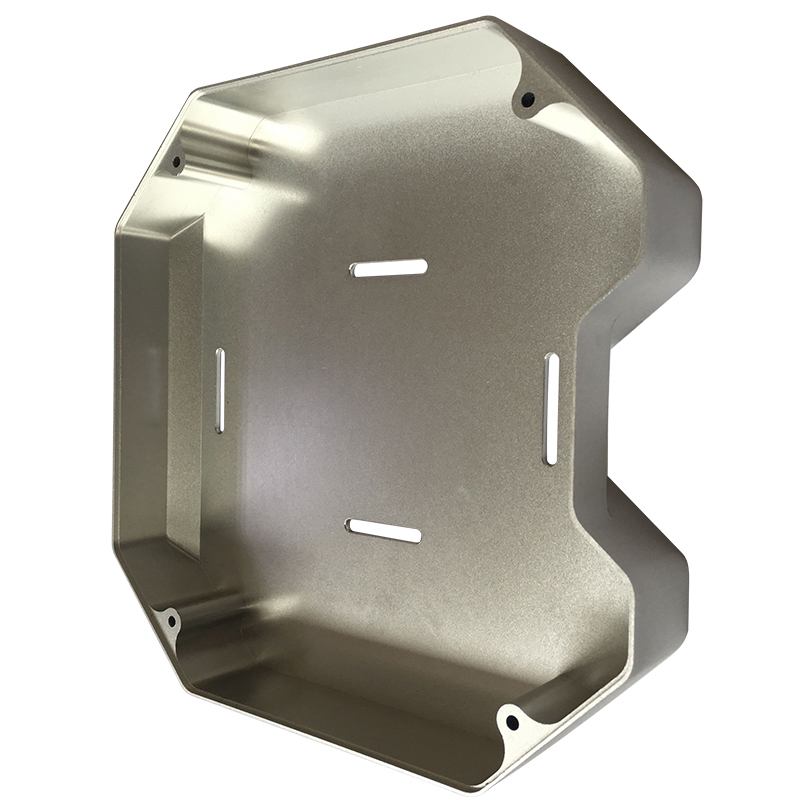

Panel and Cover Parts

In the aluminum CNC machining parts of panel and cover parts, panel and cover structural parts are often encountered, and the thickness is generally between 3 and 20mm. For such parts, the following methods can be used for processing. In the method of clamping, the method of pressing the edge of the platen is adopted.

The blank of the part leaves a margin of 5~8mm for the edge of the platen, the cutting allowance of the milling cutter, and the gap of 1~2mm between the tool and the platen. , In order to protect the worktable, a backing plate can be added to the bottom of the CNC machining parts, and the number of pressing plates can be increased on the long side of the CNC machining parts to ensure that the blank sheet does not vibrate during the processing.

Using this method for clamping, because the CNC machining parts are firmly pressed by the pressing plate, not only the relative position of the parts will remain unchanged during the machining process, but also the rough machining process of the blank shape can be omitted, so that the aluminum CNC machining process can be achieved. The internal shape and shape of the parts are processed in one clamping, which ensures the dimensional accuracy and positional accuracy of the parts, especially for plate parts with rounded corners, chamfers, bevels and other shapes.

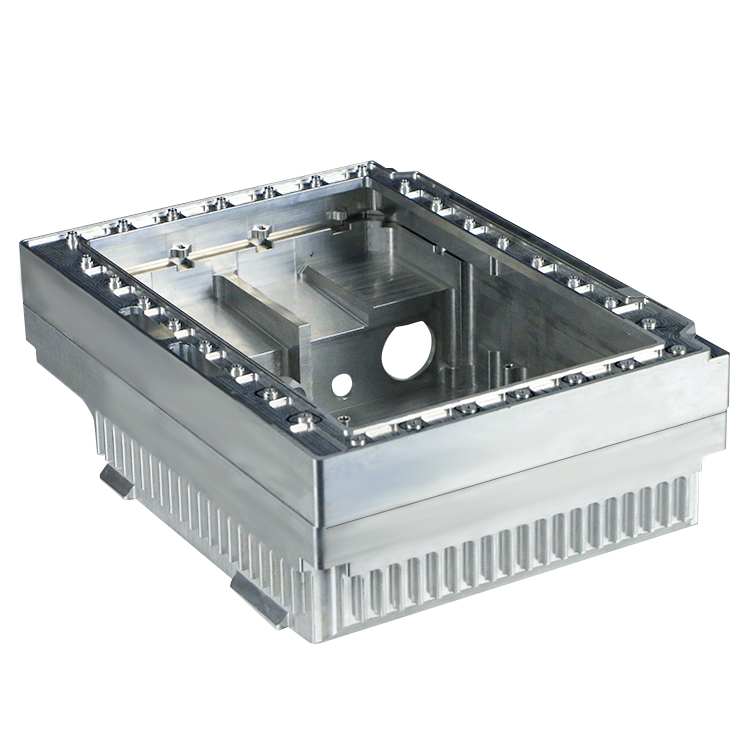

CNC Machining of Internal Cavity Parts

The CNC machining of internal cavity parts refers to CNC machining that does not need to process the external shape, but only needs to process the internal cavity. The upper and lower surfaces generally have a regular rectangular or circular shape, and the shape can be obtained by ordinary machine tools.

In the process of processing such aluminum CNC machining parts, only the internal cavity is processed on the CNC machine tool, and the shape is processed into a square or circular blank by an ordinary machine tool, so that the process resources can be used more reasonably and effectively. The shape of the blank can be directly loaded by parallel clamps or discs.

Because the processing material is in the inner cavity of the blank, in order to reduce the CNC machining process and save the turnaround time, it is best to use the over-center cutting edge tool for CNC machining, so that the oblique or helical feeding method can be directly used without pre-drilling process. hole.

CNC Machining of External and Internal Cavity Parts

The CNC machining of the shape and internal cavity parts refers to the CNC machining of the shape and internal cavity of the part that needs to be carried out at the same time under the condition of one clamping. The parts processed by the internal cavity are more complex. Generally, it is required to process the complex cavity and shape at the same time through one clamping on the CNC machine tool, which can ensure the relative accuracy between the shape and the internal cavity of the aluminum CNC machined part. Reduce the number of card installations and improve the efficiency of CNC machining.

The installation of parts should be installed in different positions according to the specific structural characteristics. Generally, there are the following two situations.

In one case, the structural characteristics of aluminum CNC machined parts provide a shape position that can be used for clamping. For example, the part has a stepped shape, or only part of the shape needs to be CNC machined, but there are still available shapes for clamping. Under the circumstance, CNC machining is realized by the way of installing the shape of the card, and the shape of the blank can be obtained by ordinary machine tools.

Another situation is that the structural characteristics of aluminum CNC machining parts do not provide a shape position that can be used for clamping. In this case, it is necessary to leave a clamping allowance through the blank, and remove the clamping after the CNC machining of the shape and cavity. margin.

There is no need for rough surface machining. For the CNC machining of some curved surfaces, if the ball cutter can directly cut into the curved surface from the outside of the blank, then the roughing process of layer cutting with a flat bottom cutter can be omitted, and the side edge of the ball cutter can be used to cut along the part shape.

Move the tool in the direction, and gradually cut into the surface. Each cutting step is adjusted according to the surface finish requirements. Generally, a step distance of 0.1~0.2mm can be selected, and the feed rate can be selected at about 5000m/min. The blank amount of the tool radius, in order to avoid a large cutting amount, can be adjusted through the structure of the digital model or the programming software to ensure that the cutting amount of the side edge meets the tool strength requirements during the initial cutting.

Using this method to process a curved surface requires that the height difference of the curved surface be smaller than the effective cutting side edge height of the ball cutter.

In summary, for aluminum CNC machining parts, to achieve the purpose of efficient and high-precision machining, the support of a variety of basic process conditions is required. In the actual processing practice, it is necessary to combine the different structures of different types of parts, according to the various basic technological conditions of the enterprise, rationally arrange the processing procedures, rationally use the process resources such as machine tools, tools, fixtures, accessories, etc., to fully utilize The role of CNC machine tools, so as to achieve efficient and high-precision machining.

CNCMF CNC machining manufacturer has a development history of 12 years, and has accumulated rich experience in the production of CNC machining parts for aluminum alloy casings. In particular, the company has strong design capabilities, which can assist customers in product structure design and cooperate with customers in new product development. .