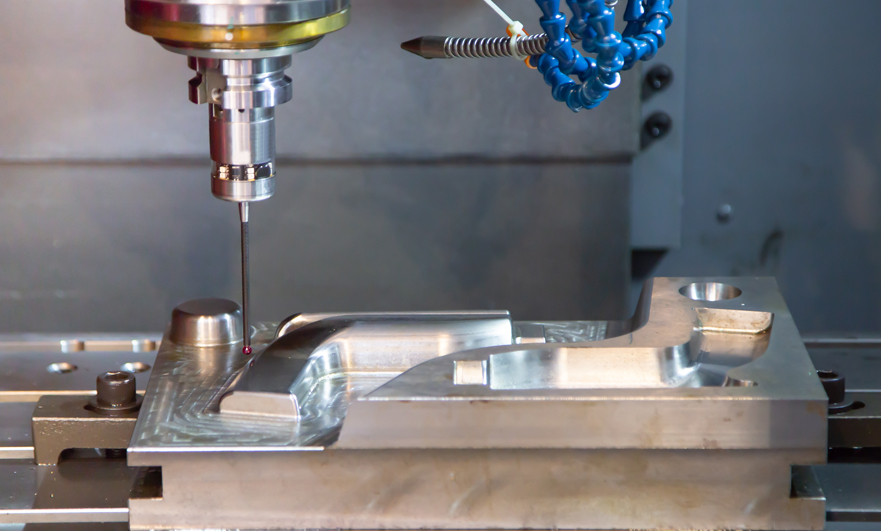

Hard cutting materials such as titanium alloys have been widely used in the aerospace industry due to their excellent high temperature performance. However, this kind of hard-cut material is difficult to be CNC machined. The cutting force and cutting temperature are high during the cutting process, and the tool wear is serious during the CNC machining process, resulting in low CNC machining efficiency. In order to improve the cutting performance and milling efficiency of titanium, a tool-workpiece meshing optimization method was proposed. The thermal-mechanical coupling effect of flat-end milling titanium alloys under different tool-workpiece effects was simulated and analyzed. According to the comparison results, it is suggested to optimize the cutting conditions to control the cutting force and cutting temperature and improve the CNC machining efficiency.

It is difficult to drill mechanically processed titanium alloys, and the phenomenon of knife burning and drill breaking often occurs in the CNC machining process. This is mainly due to several reasons such as poor sharpening of the drill bit, untimely chip removal, poor cooling and poor rigidity of the process system. Therefore, the following points must be paid attention to in the CNC machining of titanium alloy drilling: Tool material: high-speed steel M42, B201 or cemented carbide. Reasonable bit sharpening: increase the apex angle, reduce the rake angle of the outer edge, increase the rear angle of the outer edge, and increase the reverse taper to 2 to 3 times that of the standard drill bit. Retract the tool frequently and remove the chips in time, pay attention to the shape and color of the chips. If the chips appear feathery or change in color during the drilling process, it indicates that the drill bit is blunt and should be replaced in time for sharpening.

Rapid tool wear caused by high temperature cutting is the main problem in the cutting process of titanium alloys. The thermal conductivity of PCD diamond tools is several times that of cemented carbide. When CNC machining titanium alloys, more cutting heat can be transferred to the outside of the cutting area through the tool, and the durability of PCD tools can reach dozens of times that of cemented carbide tools. Polycrystalline cubic boron nitride (PCBN) tools are next, and TiC-based carbide tools and ceramic tools are considered unsuitable for titanium alloy cutting due to poor durability.

In terms of PCD tool angle, a smaller rake angle is generally used when cutting titanium alloys to increase the contact length between the chip and the rake face; at the same time, a larger clearance angle is selected to reduce the flank and the precision CNC machined. Friction between machined part surfaces.

Rapid tool wear caused by high temperature cutting is the main problem in the cutting process of titanium alloys. The thermal conductivity of PCD diamond tools is several times that of cemented carbide. When CNC machining titanium alloys, more cutting heat can be transferred to the outside of the cutting area through the tool, and the durability of PCD tools can reach dozens of times that of cemented carbide tools. Polycrystalline cubic boron nitride (PCBN) tools are next, and TiC-based carbide tools and ceramic tools are considered unsuitable for titanium alloy cutting due to poor durability.

Titanium Alloy Grinding

Vitrified CBN grinding wheels, electroplated CBN grinding wheels and vacuum brazed CBN grinding wheels are recommended for grinding titanium alloys.

1. Under ordinary grinding conditions, the grinding rate of SiC grinding wheel to titanium alloy is only about 1. If CBN grinding wheel is used, the grinding ratio will be increased by dozens or even hundreds of times.

2. Compared with ordinary abrasives, the thermal conductivity of super-hard abrasives is significantly improved, and the material removal rate is higher.

3. Using CBN grinding wheel to grind titanium alloy can avoid frequent grinding wheel dressing and further improve grinding efficiency.

4. The surface quality of CBN grinding wheel is better than that of SiC grinding wheel. The surface integrity of precision CNC machining parts is better, and the macro cracks and surface damage are relatively less. The roughness of CBN grinding wheel is better than that of SiC grinding wheel, and a comparison is made.