Zinc alloys are alloys composed of other elements based on zinc. Commonly added alloying elements are aluminum, copper, magnesium, cadmium, lead, titanium and other low-temperature zinc alloys. Zinc alloy has low melting point, good fluidity, easy fusion welding, brazing and plastic machining, corrosion resistance in the atmosphere, and easy recycling and remelting of residual waste; however, the creep strength is low, and it is prone to dimensional changes caused by natural aging. Prepared by melting, die casting or pressure processing. According to the manufacturing process, it can be divided into cast zinc alloy and deformed zinc alloy.

Zinc CNC machining parts have corrosion resistance and strong plasticity. They are mainly used for: lock cylinders, furniture accessories, auto parts, household appliance accessories, ships, light industry, mechanical workpieces, batteries, decorations, metal toys, balance weights, Eccentric wheel and other industries.

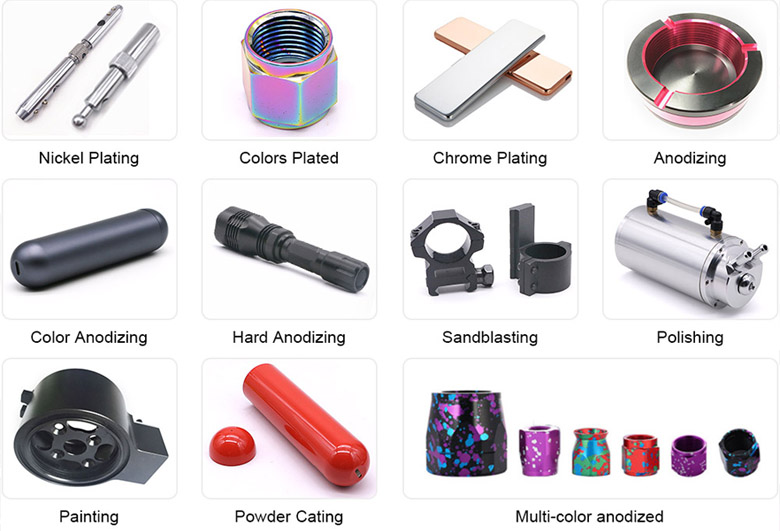

What are the common surface treatments of zinc CNC machining parts?

Zinc alloy die castings are usually used in the periphery of electronics and electrical appliances. The excellent appearance and corrosion resistance of zinc CNC machined parts are important and necessary characteristics. Zinc alloy surface treatment generally has the following forms: electroplating, painting, chemical film forming, electrostatic spraying, sandblasting, polishing, electrophoresis, etc.

Which industries are zinc CNC custom parts suitable for?

Zinc CNC machining parts are widely used because of their excellent characteristics. Zinc alloy die-casting parts are: smart home, sports equipment, electronic casings, digital products, Bluetooth audio, medical machinery, headphones, smart watches, etc. These products are all products that everyone cannot live without. They were made of plastic before, but now they are almost replaced by zinc alloy die-casting CNC machining parts. In the past two years, more and more high-end products have entered everyone’s attention, and many products are in direct contact with the skin. Therefore, the requirements are also high. Now all zinc alloy die-casting products are environmentally friendly and must pass environmental protection certification.

How to deal with the blackening of the surface of Zinc CNC machining parts so as not to corrode the raw materials?

First, use zinc alloy degreasing and degreasing powder OY-126 to deoil and clean zinc alloy die castings. After the degreasing cleaning is completed, wash it with water, and then use the aluminum degreasing and whitening agent aluminum whitening agent OY-122B to activate the zinc alloy die castings. After the activation treatment is completed, wash it with water, and then use the zinc blackening agent normal temperature zinc alloy blackening agent OY-115A to blacken the zinc alloy die-casting parts. After the blackening is completed, wash it with water, immerse it in OY-104A, a small part sealing oil of fine chemicals, and carry out oil sealing treatment.

The oxidation of Zinc CNC machining parts involves many factors such as the inside and outside of the workpiece, technology, storage and so on. Therefore, we must do a good job of anti-oxidation in the process of storage, cleaning, transportation, and die-casting inspection.

From the perspective of cleaning agent, antioxidant, process, storage environment, storage method, etc., cleaning technology can be used to solve the moldy problem of zinc alloy die castings.

The surface of zinc alloy die-casting parts is black, especially after machining, it will be more obvious, showing black spots and black spots. This situation may be due to insufficient pressure during die casting and insufficient density of the workpiece, so capillary pores are formed, and this problem occurs after these capillary pores absorb water and are oxidized. Therefore, it is still necessary to start with the die-casting process to solve the problem.

In addition, impurities, mold release agents, etc. will also cause blackening of the surface of the zinc CNC machined parts. It is recommended to use natural color anodizing for surface treatment to eliminate the problem of surface blackening.