CNC metal parts grinding is used quite frequently in our production and life process, although in the eyes of most ordinary people, CNC metal parts grinding is very unfamiliar, and some people do not know CNC metal parts grinding at all The concept and use of CNC metal parts, even the original meaning of CNC metal parts grinding can not be understood. Such a good thing that has been serving our life, a good helper, should let more people know about CNC metal parts grinding, then let us understand what is CNC grinding, and learn about the classification of grinding and features!

What is grinding?

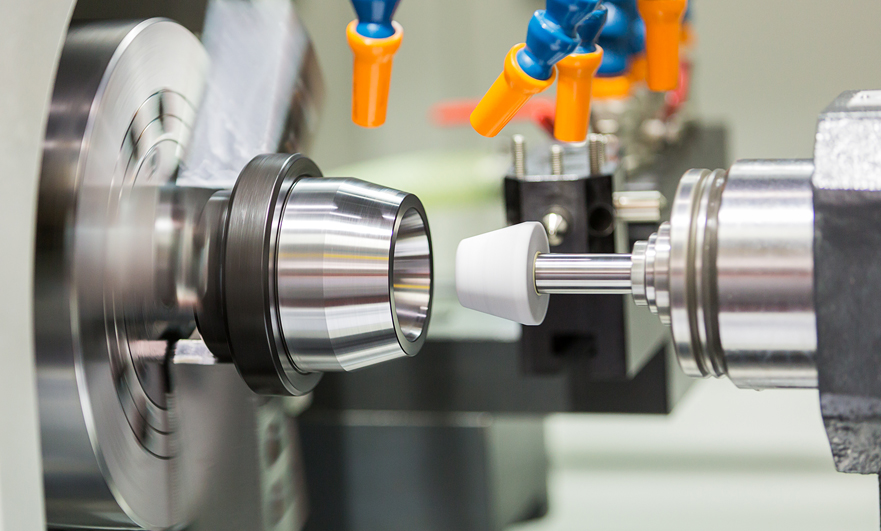

Grinding refers to the processing method of removing excess material on CNC metal parts with abrasives and abrasive tools. According to different process purposes and requirements, grinding processing methods have various forms. In order to meet the needs of development, grinding technology is moving towards precision, low Roughness, high efficiency, high speed and automatic grinding direction.

Classification of CNC metal parts grinding

There are many forms of grinding processing methods. In production, grinding mainly refers to grinding with grinding wheels. In order to facilitate use and management, grinding processing methods are usually divided into four methods according to the grinding processing form and processing objects of grinding machine products:

1. According to the grinding accuracy, it is divided into rough grinding, semi-finishing, fine grinding, mirror grinding and super-finishing.

2. According to the feed form, it is divided into plunge grinding, longitudinal grinding, slow feed grinding, no-feed grinding, constant pressure grinding, and quantitative grinding.

3. According to the grinding form, it can be divided into belt grinding, centerless grinding, face grinding, peripheral grinding, wide grinding wheel grinding, forming grinding, profiling grinding, oscillation grinding, high-speed grinding, strong grinding, Constant pressure grinding, manual grinding, dry grinding, wet grinding, grinding, honing, etc.

4. According to the surface of CNC metal parts, it can be divided into cylindrical grinding, internal grinding, surface grinding and sharpening (gear grinding and thread grinding)

In addition, there are many ways to distinguish, for example, according to the type of grinding tools used in grinding: the grinding method of fixed abrasive abrasives and the grinding method of free abrasives. The grinding methods of abrasive abrasive tools mainly include grinding wheel grinding, honing, abrasive belt grinding, electrolytic grinding, etc.; the processing methods of free abrasive grinding mainly include grinding, polishing, jet machining, abrasive flow machining, vibration machining Etc. According to the level of grinding wheel linear speed Vs, it is divided into: ordinary grinding Vs<45m/s, high-speed grinding 45m/s<=Vs<150m/s and ultra-high-speed grinding>=150m/s. According to the new technology adopted The situation is divided into: magnetic grinding, electrochemical polishing, etc.