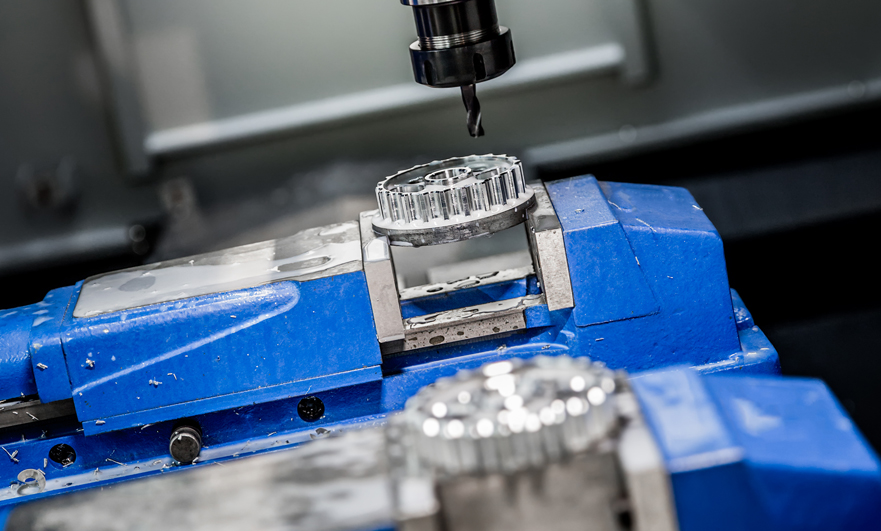

It is generally believed that the cutting speed and feed speed are 5~10 times higher than the traditional processing method called CNC milling machine high-speed cutting (processing). It is a metal processing method for CNC machine tools. At present, the spindle speed of CNC milling machines suitable for high-speed cutting exceeds 1000 r/min, and some are as high as 100,000 r/min. The tool speed and feed rate are much faster than the traditional cutting speed, so that the cutting thickness becomes smaller, so the chip is much thinner than the traditional cutting.

According to the Solomon curve, if the cutting speed is as high as a certain level (for example, 10 times the traditional cutting speed), the cutting temperature will be lower than that of traditional cutting. Mold processing generally uses small-diameter ball-end milling cutters for high-speed milling. The machine speed is required to reach 20000~40000 r/min, the feed speed is low, the machine rigidity is good, high-speed cutting can process hardened steel, the hardness is greater than 60 HRC, and the roughness is 0.8 um, the processing efficiency is twice that of EDM.

High speed cutting advantage

1. The feed rate of high-speed cutting is 5-10 times that of traditional cutting, which can save about 30% of the processing time.

2. It can process thin-walled workpieces, such as aluminum with a wall thickness of 0.5mm, which requires less cutting force.

3. The shortcomings of traditional rough machining and finishing are eliminated, and the accuracy of the machined surface is improved.

4. The cutting speed is faster than the heat transfer speed. It can also avoid warping of the workpiece due to heating. Most of the heat remains on the chip and cannot be transferred to the workpiece.

5. Hard materials can also be used for high-speed cutting, even materials with a hardness of 60 HRC (such as alloy steel parts after heat treatment). In this way, no additional hardening process is required after processing, and the risk of hardening process is also eliminated.

Disadvantages of high-speed cutting

1. The ultra-high speed of high-speed cutting requires equipment to improve its safety protection in the workplace. High-speed small chips have a fairly high flight speed, which may even be faster than the movement of gun bullets. The tool is easier to use, but it will also greatly reduce the life of the tool. However, the time required for material processing has to be greatly shortened.

2. High-speed cutting also has high requirements on the balance of the tool. If it is not balanced, it will produce a lot of force to damage the tool and have a strong impact on the position of the spindle. Due to the extremely high speed and load of high-speed cutting, the consumption rate of parts is very high. Therefore, machine maintenance and spindle and tool replacement are often required, which greatly increases the cost.

In order to give full play to the performance of high-speed milling, all aspects of processing must be closely coordinated. If one of the links does not match, the performance of high-speed milling will be poor or successful.

1. High-speed tool rack and tools

Since the actual cutting action is determined by the tool rather than the machine, the choice of tool is very important.

2. High-speed spindle

Bearing: high torque

Bearingless (air drive): low torque.

3. Highly dynamic XYZ axis

Traditional hard rails can be adjusted on the machine to obtain better accuracy, but they cannot achieve the high-speed machining that linear slide rails can achieve. High-power and high-speed XYZ axis can reduce the waste of time for each axis. It can make the cutting surface better and reduce tool wear.

4. High-speed cnc controller

With sensitivity and rapid response ability.

5. High-speed programming strategy

Analyze materials, surfaces and processing paths to determine the most effective process.