We look at CNC machine tools with a very high feeling. For CNC machining technology, ordinary CNC machining technology is its foundation and technical guarantee. CNC machining technology is a combination of traditional machining technology, computer numerical control technology, and computer-aided design technology. and computer manufacturing technology. Where is the difference between them? CNCMF’s 12 years of experience in CNC machining of precision parts tells you.

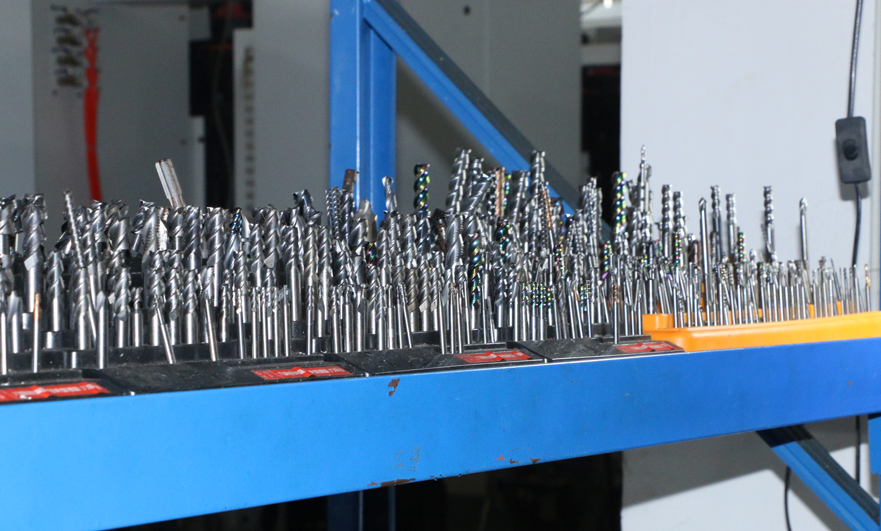

1. Differences in tool selection: The tools required by different CNC machining processes and methods are definitely different, especially in high-speed cutting, the CNC machining efficiency and quality of CNC machine tool precision parts have been greatly improved, as well as cutting deformation and CNC machining. cycles are greatly reduced. Compared with the traditional CNC machining process, precision CNC machining has significantly enhanced performance requirements for all aspects of the tool, and the installed tools have changed from a single tool to many tools.

2. Differences in CNC machining methods: The CNC machining methods that should be used carefully in the traditional mechanical CNC precision parts machining technology will become simple and feasible in CNC machining. During hole machining, the empty knife method and trimming method used in the traditional CNC machining process are replaced by the CNC trimming method in the CNC machining process.

3. The high-speed machining in the machining of precision CNC parts has the incomparable advantages of the traditional CNC machining process. The following takes mold machining as an example to explain in detail. In the traditional machining process, multiple CNC machining processes are usually required to complete the mold machining task, but only 1-2 processes are required for high-speed machining. The two processes of electrical machining and grinding.

4. Differences in thermal deformation: Thermal deformation is one of the inevitable problems during workpiece cutting. When the parts are processed by precision CNC, thermal deformation will have a direct impact on the machining accuracy.

The traditional machining method has many processes, and the connection of each process has a certain buffer time, which can reduce the temperature of the precision CNC machined parts before proceeding to the next process, effectively reducing the influence of thermal deformation.

CNC machining can process multiple surfaces continuously, and the cutting heat cannot be released in time. If it is prevented by controlling the time interval of each process, it will affect the efficiency of CNC machining of mechanical precision parts. Therefore, when CNC machining of high-precision mechanical CNC machining parts is adopted, it is also necessary to adopt the method of cooling first and then finishing to reduce the influence of thermal deformation. CNCMF provides you with CNC machining of precision parts, CNC machining of aluminum casings, CNC machining of non-standard plastic parts, etc.