There are various raw materials for CNC machining goods, among which CNC machining aluminum parts is one of the most processed. When applying CNC machining of aluminum parts, if you want to make the CNC machining model specifications more stable, you must pay attention to such areas.

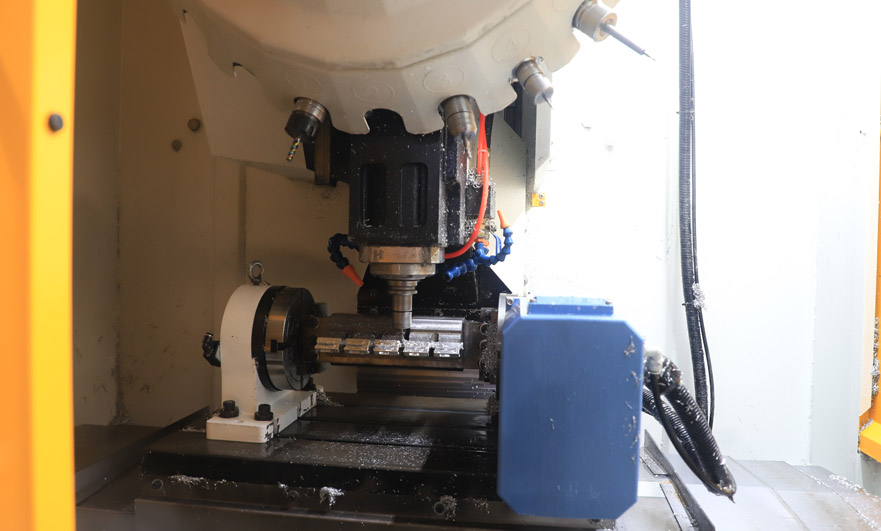

Machine tool situation

Whether the CNC machining is stable or not depends on the condition of the machine tool itself. Before processing, everyone should check the machine tool itself and start the industrial equipment after everything is normal.

Raw material refrigeration problems. Aluminum die castings may deform after cooling. This kind of thing is generally unavoidable, and then try to pay attention to the application of diesel engine refrigerant. When carrying out accurate and precise measurements, it is also necessary to take into account the deformation of the raw material.

CNC machining process

The unscientific CNC machining process can easily lead to the deviation of the model specifications of aluminum die castings. In ensuring the basic CNC machining process (such as “coarse first, then fine, face first, then hole, first a lot and then spicy noodles” in CNC machining, or “reduce the frequency of clamping and use as much as possible to form tooling fixtures” in the application of welding fixtures, etc. Most of the important links of basic CNC machining process), it is necessary to try to avoid CNC machining deviation caused by iron pins to CNC machined aluminum parts.

Basic parameters

Cutting factors such as cutting rate, cutting speed, cutting aspects and tool compensation all damage the efficiency of CNC machining, so special attention should be paid to it.

Tool selection

When CNC machining aluminum parts, special tools should be used as much as possible, and such tools are generally more purposeful. For example, the rake angle and helix angle of the special type of turning tool for milling aluminum will be larger, and the cutting edge will be sharper, which is more conducive to CNC machining of aluminum parts (such as anti-chip edge), and the performance indicators of CNC machining will be stronger.

Stress field level

The raw material of CNC machined aluminum parts is too soft, so try to pay extra attention to the clamping range. In addition, in CNC machining, the CNC machined aluminum parts are roughed and intact for a period of time before the next production process is carried out to remove the stress field.

In addition, in CNC machining of aluminum parts, attention should be paid to the milling surface and the demand for cutting fluid. There are many factors that damage the efficiency of CNC machining of aluminum parts, so it should be handled flexibly during CNC machining, and the actual problems should be analyzed in depth. Stable machine tools, effective CNC machining processes and tools, and the technical prowess of their operators are all factors that compromise product quality.

Tool selection

When CNC machining aluminum parts, try to use special tools, which are generally more targeted. For example, the rake angle and helix angle of the lathe special for milling aluminum will be larger, and the cutting edge will be sharper, which is more beneficial to CNC machining of aluminum parts (such as anti-built-up edge), and the performance of CNC machining will be stronger.

In addition, in CNC machining of aluminum parts, special attention is paid to the difficulties such as milling surface and the requirement of cutting fluid. There are many factors that damage the reliability of CNC machining aluminum parts, so it should be handled flexibly during CNC machining, and the specific difficulties should be analyzed in detail. Stable machine tools, reasonable CNC machining technology and tools, and the technical level of operators are all factors that hurt product quality.

CNC machining process

The unreasonable CNC machining process can easily cause the specification and model error of the cast iron. In ensuring the basic CNC machining process (such as “coarse first, then fine, first face and then hole, first a lot and then spicy noodles” in CNC machining of CNC machine tools, or “reduce the number of clamping and use as much as possible to form tooling fixtures” in the use of fixture tooling, etc. Most of the key links of the basic CNC machining process), it is necessary to minimize the CNC machining errors caused by iron pins to aluminum parts.

There are many reasons for the deformation of CNC machining aluminum parts, which are often related to raw materials, part shape, and production CNC machining specifications. There are several important aspects: deformation caused by blank welding stress, deformation caused by cutting force and cutting heat, and deformation caused by clamping force.

CNCMF has been focusing on and precipitating a perfect supply chain system for 11 years, with more than 100 Top10 international first-line brand CNC machining centers and perfect testing equipment to meet customer requirements for precision CNC machining of aluminum parts; a team of engineers with 20 years of experience per capita, with Strong R&D, design, production, assembly capabilities, providing one-stop industrial supporting services for customers in different fields such as medical, semiconductor, automation, automotive, optics, etc. Welcome to map customization!