From rough machining to CNC machining of the finished product, the total thickness of the metal layer removed on the CNC machining surface is called the total CNC machining allowance of the CNC machining surface. The thickness of the metal layer removed from each process is called the CNC machining allowance. For the outer surface of the circumference and the hole, the CNC machining allowance is considered from the diameter, which is called the symmetry allowance (ie, bilateral allowance), that is, the diameter that actually cuts off the metal layer thickness by half of the allowance.

The plane CNC machining allowance is the one-side allowance, which is equal to the thickness of the actual cut metal layer. The purpose of leaving the CNC machining allowance on the CNC machining parts is to eliminate the CNC machining errors and surface defects left in the previous CNC machining process, such as cooling layer, pores, sand layer on the surface of castings, oxide layer on the surface of forgings, and delamination. Carbon layer, surface cracks, etc. The internal stress layer and surface roughness after cutting. Thereby improving the accuracy and surface roughness of CNC machined parts.

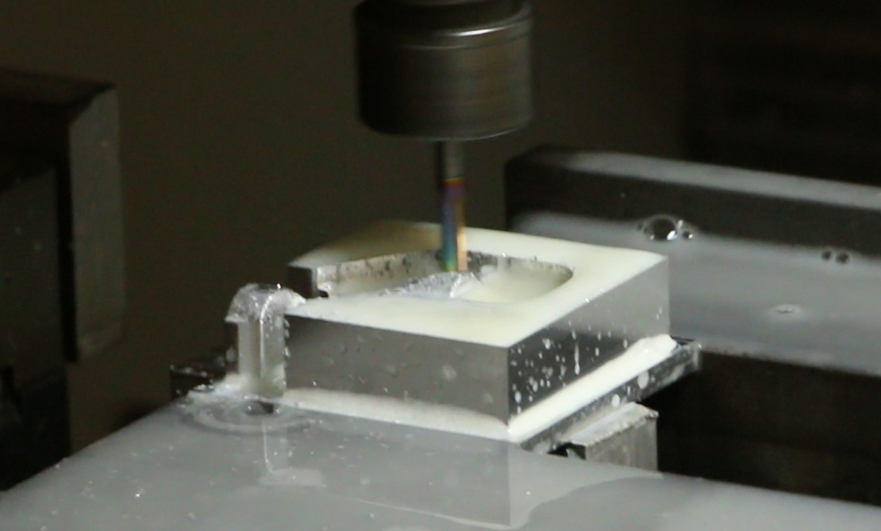

CNC machining technology is based on the CNC machining process, changing the shape, size, relative position and nature of the production object to make it a waste or semi-finished product. Detailed description of each method and each process, such as the above rough machining is possible, including blank manufacturing, grinding, etc. CNC machining can be divided into turning, fitter, milling machine, etc., each method must have detailed data such as Roughness and tolerance.

The size of the CNC machining allowance has a greater impact on the CNC machining quality and production efficiency. Excessive CNC machining allowance not only increases the labor of CNC machining, reduces productivity, but also increases materials, tools and power consumption, and increases the cost of CNC machining. If the CNC machining allowance is too small, it will not be able to eliminate various defects and errors in the CNC machining process, nor can it compensate for the clamping errors in the CNC machining process, resulting in waste products. The principle of selection is to minimize subsidies under the premise of ensuring quality. Generally speaking, the more processing, the smaller the work margin.

In order to produce qualified CNC machining parts, the thickness of the metal layer that must be cut off is called CNC machining allowance. CNC machining allowance can also be divided into work allowance and total allowance. The thickness of the metal that needs to be removed in the CNC machining process is called the CNC machining allowance. The total margin that needs to be removed from the blank to the finished product is called the total margin, which is equal to the sum of the margins of each process on the corresponding surface.