Fixtures are indispensable parts of CNC machining equipment. Each CNC machining equipment uses jigs. According to the different CNC metal machining parts to be processed, the clamps used are also different, and the requirements for the clamps are also different. However, CNC machining equipment also has similar requirements for fixtures.

According to the traditional single-piece processing method, the processing time of the main process is much shorter than the auxiliary time such as CNC metal machining parts clamping time and tool change time, resulting in low production efficiency and high labor intensity. A well-designed fixture can realize multi-piece or small batch production, which not only reduces the labor intensity of workers, but also greatly shortens the auxiliary time, which improves CNC metal machining parts efficiency while ensuring product quality.

What is CNC metal machining parts fixture?

CNC metal machining parts fixtures are mainly used for workpiece clamping equipment. The key is to properly fix the workpiece, support point or install it on the CNC lathe. It has the function of stable and precise positioning.

Design principles of multi-piece clamping tooling

Whether the tooling design is reasonable or not directly affects the quality, production efficiency and cost of the CNC metal machining parts.

In actual production, the design of fixtures is mainly based on the processing technology plan and the experience of the operators. Minimize the number of clamping and tool changes, complete multiple procedures at one time, save auxiliary time and improve CNC metal machining parts production efficiency.

When designing the fixture, while ensuring the CNC metal machining parts accuracy, it should follow the principles of reasonable structure, low cost, and convenient installation and disassembly.

Fixture classification

1. Flat nose pliers

Features: Easy clamping, fast and reliable, accurate positioning, suitable for various square parts, but not suitable for clamping thin plate parts.

Flat nose pliers have greater versatility and economy, and are suitable for clamping small square CNC metal machining parts; V-shaped grooves or V-shaped blocks on the clamping jaws can also clamp cylindrical surfaces.

Mechanical screws, pneumatic or hydraulic clamping methods are often used.

(a) Spiral clamping universal flat nose pliers

(b) Hydraulic sine gauge flat nose pliers

(c) Pneumatic precision flat nose pliers

(d) Hydraulic precision flat nose pliers

2. Magnetic suction cup

Features: The clamping is convenient and reliable, and the scope of application is wide, but the material of the CNC metal machining parts must be a magnetic material.

3. Press plate and bolt

Features: Clamping and alignment require more time. CNC metal machining parts programming should consider the position and height of the pressure plate to avoid knife collision. The method of bolt passing through the process hole takes up less space and is easy to give way, but the hole position should be exactly the same as the T-slot position of the machine tool, otherwise it needs to be specially made. The back plate requires bolts, which is more troublesome. They are most suitable for special-shaped CNC metal machining parts, large-size parts and parts that cannot be clamped with flat-nose pliers.

For CNC metal machining parts with large size or irregular surroundings, when flat-nose pliers or other fixtures cannot be used to clamp, the splint can be used directly, or the CNC metal machining parts can be pressed directly through the process hole with bolts.

(a) Spiral clamping universal flat nose pliers

(b) Hydraulic sine gauge flat nose pliers

(c) Pneumatic precision flat nose pliers

(d) Hydraulic precision flat nose pliers

4. Chuck

Features: Easy and reliable clamping, automatic centering, suitable for cylindrical CNC metal machining parts.

According to the number of jaws, it can be divided into two-jaw chuck, three-jaw self-centering chuck, four-jaw chuck, and six-jaw chuck. Three-jaw self-centering single-action chuck and four-jaw chuck are widely used in CNC milling machines and CNC metal machining parts centers.

Especially the three-jaw self-centering chuck, due to the self-centering function, is convenient for clamping. Therefore, three-jaw self-centering single-action chuck is often used for clamping when machining small and medium-sized cylindrical CNC metal machining parts on CNC milling machines or machining centers. The clamping of the chuck has various forms such as mechanical screw type, pneumatic type or hydraulic type.

5. Vacuum fixture

It is used to locate CNC metal machining parts with larger flat surfaces or larger sealable areas. Some CNC milling machines (such as wall milling machines) have their own general vacuum platform. When installing the CNC metal machining parts, use a special rubber strip (hollow or solid circular cross-section with a certain size) to put the rectangular blank with a regular shape into the sealing groove of the fixture, and turn on the vacuum pump to clamp the blank.

Rubber strips are not suitable for CNC metal machining parts blanks with irregular shapes, so putty (commonly used plasticine) must be coated around them for sealing. This is not only cumbersome, but also time-consuming and inefficient. To overcome this difficulty, a special transition vacuum platform can be used and superimposed on the general vacuum platform.

6. 3R fixture system

Features: convenient and reliable clamping, high repeat positioning accuracy, especially suitable for CNC metal machining parts mold electrode production.

7. Special fixtures, modular fixtures and group fixtures

When the machining center is processing small and medium batches of CNC metal machining parts, the combined fixture can be used for clamping. When processing large quantities of CNC metal machining parts, most of them use special fixtures or group fixtures for clamping, but because the machining center is more suitable for single-piece and small-batch CNC metal machining parts. Therefore, such fixtures are not used much on CNC machine tools.

8. Indexing head

When many mechanical CNC metal machining parts, such as splines, clutches, gears and other parts are processed on a machining center, the indexing method is often used to divide each tooth slot into equal parts to produce qualified CNC metal machining parts.

Application of multi-piece clamping tools

Screw tooling design

The screw CNC machining technology is simple, the main CNC metal machining parts are concentrated at the two ends (the middle outer surface is not processed, and the anti-corrosion paint is sprayed). When milling both sides of the traditional processing technology, the three-jaw self-centering chuck can only be clamped one piece at a time, which has a long auxiliary time for clamping and low production efficiency. But the screw production volume is large, the construction period is short, and the single-piece CNC machining may delay the construction period.

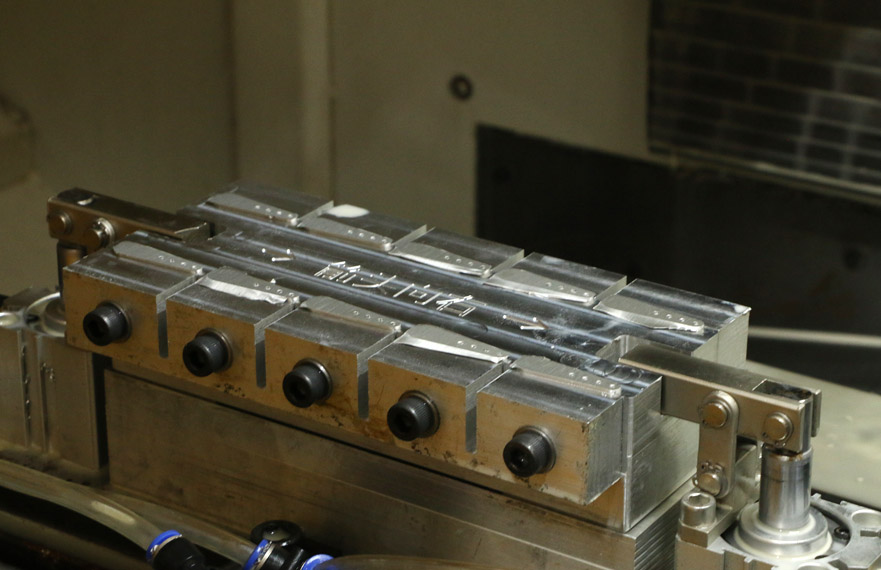

After special tooling design, 8 pieces CNC metal machining parts can be clamped at a time. The tooling adopts 8 φ15mm counterbore positioning. A 2mm wide through slot is opened in the center of every two holes to form a half-opening hole. The tooling adopts 7A04 super-duralumin, which has high strength.

Due to the low roughness of the outer surface of the middle of the screw, after the CNC metal machining parts is installed, the clamping force of the precision vise is used to cause a small amount of elastic deformation of the tooling, and the workpiece is clamped to realize multiple CNC metal machining parts. After using multi-piece clamping, 4 sides can be milled at a time, the tool stroke is greatly reduced, and the production efficiency is increased by nearly 3 times.

Due to the limited jaw height of the precision vise, if the screw length is greater than 80mm, the above tooling will not be able to use the clamping force of the precision vise to fix the CNC metal machining parts. Therefore, a special tooling fixture for long screws was designed according to the annual output. The tooling also uses 8 locating holes with the same diameter as the screw for positioning, and milling chip flutes under the 8 locating holes to facilitate the cleaning of the tooling fixture.

The tooling can clamp 8 pieces at a time, and every two pieces are clamped by a special pressing plate to realize multiple pieces of CNC metal machining parts. After using the fixture, 8 faces can be milled at a time, the tool movement stroke is short, the auxiliary clamping time and tool change time are significantly shortened, and the production efficiency is significantly improved.

Tooling design of pin shaft CNC metal machining parts

In the past, similar workpieces were machined with modular fixture V-blocks. Usually, two pieces are processed at a time. Long auxiliary time and frequent tool change affect CNC metal machining parts efficiency. After the fixture design is completed, the 8 V-shaped grooves are used as the positioning reference, and the overall positioning surface is the length direction positioning reference. 8 pieces are clamped each time, and every two pieces are pressed by the pressing plate to realize multiple CNC metal machining parts.

This clamping method provides auxiliary support for the pin shaft, which can effectively reduce internal stress and deformation. The tooling has universality in the processing of pin shaft CNC metal machining parts. It can be used for pin positioning of φ18~φ25mm, and the operation is simple. Compared with before the improvement, the clamping efficiency has increased by nearly 75%. The total production efficiency is increased by about 35% every year. Nearly 20,000 pieces of such CNC metal machining parts are processed, and the economic benefits are considerable.

Valve stem tooling design

The traditional processing method of the valve stem is to clamp one at a time with a combined fixture on a four-axis vertical machining center, and mill the grooves and planes at both ends. After the tooling design is completed, multiple pieces CNC metal machining parts are processed on the chuck of the four-axis vertical machining center, 4 pieces are clamped each time, and the milling and leveling processes are completed.

The tooling uses four V-shaped grooves as the workpiece positioning reference, and every two pieces are clamped by a special pressing plate to realize multi-piece CNC metal machining parts, reduce the frequency of tool change, and improve production efficiency. One side of the tooling is designed in a hexagonal shape, and the three-jaw self-centering chuck is convenient for centering and reliable for positioning when clamping and positioning. After adopting multi-piece clamping, the production efficiency is increased by 50%.

In summary

CNC fixture is an important tool. This article explains the characteristics and applications of the tool. Different shape CNC metal machining parts use different fixtures to improve part quality and CNC machining time.

In the process of drilling, milling, tapping and chamfering of screw, valve stem and pin shaft parts, the tool change frequency is high, the machine movement stroke is long, the auxiliary time for frequent CNC metal machining parts loading and unloading increases, and the production efficiency is low.

The development of multi-piece clamping tools has shifted from single-piece processing to multi-piece CNC metal machining parts. Under the premise of ensuring quality, it not only reduces labor intensity, but also improves production efficiency. Multi-piece clamping is widely used in production and has significant economic benefits.

Understanding the application of fixtures can make your time cost in the CNC machining process not a big problem, and deliver you faster. If you need CNC metal machining parts, please contact us. We have professional CNC machining engineers to solve the CNC metal machining parts time cost and give you the best solution. Welcome to consult our customer service. We look forward to you starting CNC metal machining parts project.