With the development of internal thread CNC machining towards high performance, low cost and low energy consumption, the use of cold extrusion to form internal thread mesh has become an important part of anti-fatigue CNC machining. It has broad application prospects in aviation, aerospace, high-speed trains and other fields. The advantages and disadvantages of various CNC machining methods are compared from the point of view of CNC machining quality and fatigue life. In order to improve the anti-fatigue service life of the internal thread, the cold extrusion CNC machining technology of the internal thread was studied. The plastic deformation law and surface integrity of the metal layer during cold extrusion are summarized to improve its stability and economy.

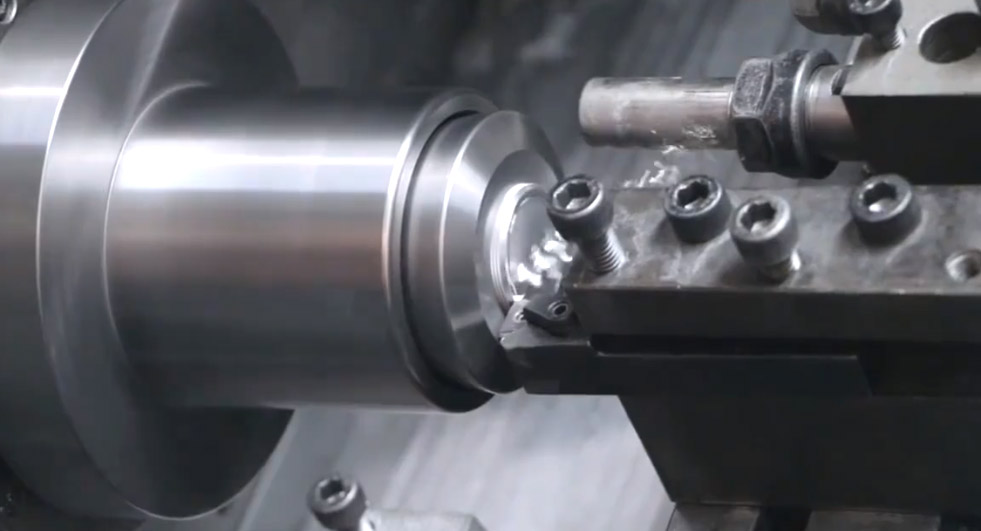

CNC metal parts CNC machining – analysis of the influencing factors of the failure of internal thread cold extrusion taps. Internal thread cold extrusion is a metal plastic CNC machining method that uses extrusion taps to process internal threads. It has the characteristics of high material utilization, high CNC machining accuracy, low surface roughness, high mechanical strength and strong fatigue resistance. Xu Jiuhua et al. conducted an experimental study on the extrusion strengthening of 300M high-strength steel internal threads. The results show that the fatigue performance of cold-extruded internal threads is significantly improved compared with cutting threads. Under the same conditions, the life of cold-extruded threads is the same as that of cutting threads. 4-30 times;

Although the internal thread cold extrusion technology can produce cold hardening on the thread surface and improve the fatigue life of the internal thread, there are still some deficiencies in the popularization and application.

(1)The demands placed on thread forming taps are high. During the cold extrusion process of the internal thread, the thread forming tap greatly improves its deformation resistance by bearing three-dimensional compressive stress. The stress of thread forming taps is much greater than that of other internal threading methods. This requires thread forming taps not only to have high strength, but also to have sufficient impact toughness and wear resistance. As a result, thread forming taps generally have a short service life.

(2)The manufacturing process of thread forming taps is complicated and the cost is high. It is usually only suitable for mass production internally threaded parts.

(3)It is not suitable for CNC machining of inclined groove threaded holes, incompletely threaded holes and thin-walled threaded holes.

(4)It is not suitable for CNC machining brittle materials and high-strength materials.

(5)The plasticity and impact toughness of the cold extrusion internal thread are poor. There is a large residual stress on the surface, which is easy to cause deformation of the internal thread.

(6)In addition to the relatively high dimensional accuracy, the cold extrusion of internal threads has higher requirements on the bottom hole of the workpiece; the surface lubrication of the workpiece is also required before cold extrusion.

The internal thread cold extrusion technology is a new type of internal thread CNC machining technology. The thread forming tap is used to make the metal pass through the edge teeth of the tap to generate plastic flow at the bottom of the prefabricated workpiece and form the internal thread at room temperature. For internal thread products manufactured by cold extrusion of internal threads, the surface quality, dimensional accuracy, material utilization and mechanical properties are better than those of traditional CNC machining methods. It is an important part of anti-fatigue CNC machining technology. Its advantages mainly include.

(1)Save raw materials. The required shape of the parts made by plastic deformation of the internal thread cold extrusion CNC machining metal. It is a non-cutting CNC machining technology. It can significantly improve the material utilization rate.

(2)Improve the CNC machining accuracy of internal threads. The shape and position error of the cold extrusion internal thread is very small. For general materials, it is easy to achieve the accuracy of 4H_5H.

(3)The workpiece can obtain the ideal surface roughness. During the extrusion process, the teeth on the thread forming tap press against the thread surface. The surface roughness of the cold-extruded internal thread can reach Ra0.4~0.8. Therefore, the cold-extruded internal thread is rarely subjected to secondary CNC machining, and only needs to be precisely ground at a particularly demanding position.

(4)Improve the mechanical strength of the internal thread. After the internal thread is cold extruded, the surface metal is cold hardened, the surface structure fiber is refined, and a reasonable streamline distribution is formed along the thread shape. There is a certain depth of residual stress field on the surface layer, which increases the tensile strength of the cold extrusion internal thread And the fatigue resistance is much higher than the tensile strength and fatigue resistance of cold extruded internal threads processed by other methods. Therefore, some internal threaded parts originally need heat treatment to strengthen, once the cold extrusion process is adopted, the heat treatment process can be omitted; some internal threaded parts originally need to be made of rolled steel with higher strength, once cold extrusion technology is used, it can be replaced with lower strength of rolled steel.

(5)Improve the CNC machining efficiency of internal threads. Using cold extrusion technology instead of other CNC machining technologies to produce internal thread parts will greatly improve production efficiency.

(6)It is suitable for the CNC machining of deep hole and blind hole threads. Since the internal thread cold extrusion process does not need to clean the chips, the possibility of tooth breakage or thread tap breakage caused by the difficulty of chip removal is reduced or avoided.

(7)reduce manufacturing cost. The internal thread cold extrusion CNC machining technology has the advantages of saving raw materials, improving production efficiency, and reducing the CNC machining volume of parts. It can replace high-quality materials with lower-level materials, thereby greatly reducing the cost of internal thread parts.

Application and performance of cold extrusion internal thread

The internal thread processed by chipless cold extrusion is superior to the internal thread processed by traditional CNC machining methods in terms of tensile strength, fatigue performance, surface hardness and other physical properties, as shown in the table. With the optimized design of the tap geometry and the improvement of continuous growth, this chipless CNC machining technology can be used in an increasingly wide range of workpiece materials.