Simply put, the main difference between iron and non-ferrous metals is the presence of iron. Ferrous metals contain iron, while non-ferrous metals do not contain iron. In a narrow sense, non-ferrous metals are also called non-ferrous metals, which are collectively called all metals except iron, manganese, and chromium. Non-ferrous metals in a broad sense also include non-ferrous alloys.

Black CNC metal parts machining

The machining of ferrous CNC metal parts contains iron, which is valued for its strength and durability. Ferrous metals mainly refer to iron and its alloys, such as steel, pig iron, ferroalloys, and cast iron. Black CNC metal parts are processed with higher carbon content and most of them are magnetic, which makes them useful in motor and electrical applications. Most ferrous alloys contain large amounts of carbon. This makes them prone to rust when exposed to moisture. The only two rust-resistant black CNC metal machining materials include wrought iron (which resists rust due to the low carbon level) and stainless steel (which does not rust due to the presence of chromium).

Common black CNC metal parts machining materials include:

Steel: widely used in construction and industrial metal manufacturing.

Carbon steel: higher carbon content added to iron; unusually hard metal

Cast iron: iron, carbon, silicon; abrasion-resistant heavy and hard metal.

Stainless steel: an alloy steel made with chromium added to prevent rust.

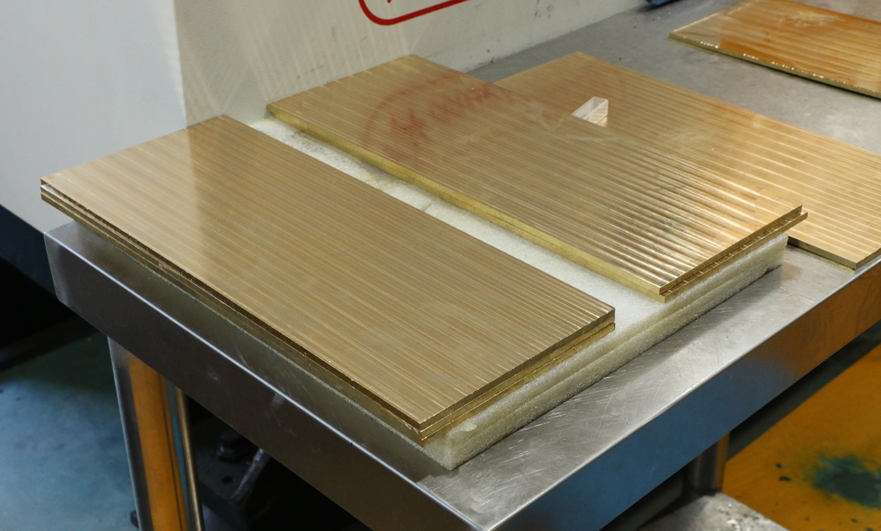

Non-ferrous CNC metal parts mahcining includes:

Non-ferrous CNC metal parts do not contain iron. Such CNC metal parts materials include common metals such as aluminum, and precious metals such as gold and silver. Non-ferrous metals have been used since the copper era in 5,000 BC. Since non-ferrous metals do not contain iron, they are generally more resistant to corrosion than ferrous metals. They are often used in industrial applications such as gutters, roofs, plumbing and electrical. Non-ferrous CNC metal parts have high ductility and can be used to make jewelry and different manufacturing purposes. These types of metals are non-magnetic, which is important for many electronic and wiring functions. Below is a list of non-ferrous metals used in CNC metal machining and manufacturing.

Lead: heavy, soft, malleable; low melting point, low strength.

Tin: A soft, malleable metal with low tensile strength. It is often used to coat steel to prevent corrosion.

Zinc: A medium-strength metal with a low melting point. It is widely used in galvanizing to prevent steel from rusting.

Copper: has high plasticity and high conductivity.

Aluminum: light weight, low strength, easy to shape.