With the advent of the era of intelligence, mobile phones have become an indispensable thing in our work and life. With the advent of the network from 4G to 5G, smart phones have brought a lot of convenience to our work and life. The production of mobile phones varies with functions. The different productions are also different.

The original shell is made of plastic and die-casting processing technology. Until now, many purchases use CNC precision machining technology to produce the aluminum middle frame of the mobile phone. The aluminum middle frame is combined with the glass panel. Briefly introduce the exploration of CNC machining technology for CNC precision machining of aluminum alloy mobile phone middle frame.

1. Based on the combination of the glass panel and the aluminum mobile phone frame, how thick is the wall thickness of the frame suitable for CNC precision machining?

The thickness of the wall thickness of the aluminum mobile phone frame is the key to the yield rate of CNC precision machining. Generally, the thickness is above 2.5mm, because the deformation will cause defects during processing, and the surface knives are unavoidable.

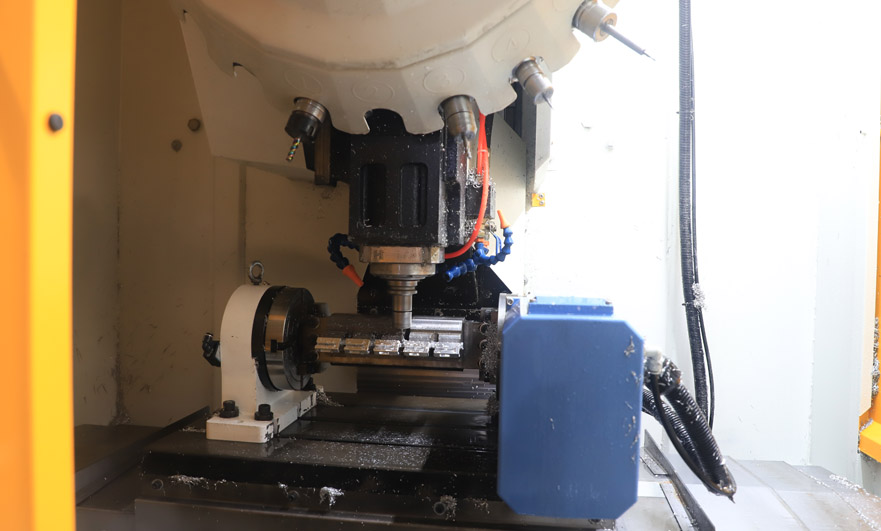

2. Fixtures in CNC precision machining

A well-designed fixture is one of the key points in the production of aluminum mobile phone middle frames. Unstable clamping will lead to unstable dimensions and slow production efficiency. CNCMF generally uses pneumatic fixtures and adopts 4-axis CNC precision machining. For production, try to process 3 sides at one time.

3. Requirements for cutting coolant

A surface without sand holes and knife marks, and a surface with a surface finish of RA 0.6 or higher, also has a great influence on the cutting coolant. First, check regularly whether the pH of the cutting fluid is too alkaline. If the content is too high, it will cause Sand holes appear on the surface of corrosion. And the cutting fluid should be changed regularly, generally every 3 months, so as not to affect the appearance, texture and quality of the aluminum mobile phone frame and CNC machined parts.

4. CNC precision rough machining

The CNC precision machining machine uses aluminum plate raw materials for rough processing. Pay attention to the reference size of the finishing process, and keep the size as small as possible to ensure the stability of the size of all aluminum mobile phone frame parts during the second finishing process. Consider the injection runner when nano-injection.

5. Nano injection molding

The aluminum mobile phone middle frame that has been precision-machined by CNC is generally made of PBT, PPS and PPA materials, and is formed by injection molds. This is a process method that combines metal and plastic through nanotechnology. After the metal surface of the aluminum mobile phone frame is nano-processed, the plastic is directly injected into the metal surface, so that the metal and the plastic can be integrally formed. The advantage is that the product is lighter, thinner, and smaller. And compared with CNC precision machining, the cost is lower.

6. Finishing

Generally, imported CNC precision machining machines are used, because the knives that are precision machined by imported CNC can be covered with 320# sand, and an apple-like aluminum mobile phone frame surface is produced.

7. CNC precision machining aluminum mobile phone frame surface polishing and grinding

For the surface processing method, we often use grinding to polish. Only when the surface of the aluminum mobile phone frame after grinding is sandblasted and oxidized can the yield rate be improved.

Summarize

Based on the above CNC precision machining process of aluminum mobile phone frame, we will strictly follow the above process when we produce CNC precision machining parts similar to Apple’s appearance grade standard. Welcome everyone to participate in the discussion to make CNC machining more efficient!