This article explores the key factors that affect the smoothness of threads in CNC precision machining parts, including the sharpness of the tool, the selection of cutting parameters, the use of coolant, and equipment accuracy and adjustment. At the same time, this article also proposes optimization methods to improve the smoothness of threads in CNC precision parts, including selecting high-quality tools, adjusting appropriate cutting parameters, rational use of coolant, regular inspection and adjustment of equipment, and improving the skill level of operators. Through these methods and measures, the smoothness of the threads of CNC precision parts can be effectively improved, thereby improving product quality and user experience.

The smoothness of the thread of CNC precision parts is affected by many factors, including the following aspects:

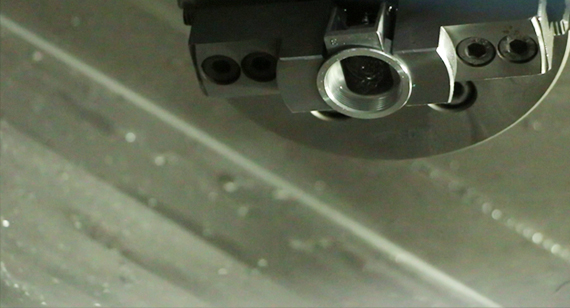

The sharpness of the tool: The sharpness of the tool directly affects the cutting force and cutting heat during the cutting process, thereby affecting the surface roughness and smoothness of the thread.

Selection of cutting parameters: Unreasonable selection of cutting parameters, such as too fast cutting speed, too large feed, etc., will cause the cutting force to increase and the cutting temperature to rise, thus affecting the surface roughness and smoothness of the thread.

Use of coolant: The use of coolant can effectively reduce the cutting temperature and reduce material deformation, thereby improving the accuracy and smoothness of the thread.

Equipment Accuracy and Adjustment: The accuracy and adjustment of CNC machine tools can also have an impact on thread feel. For example, the accuracy of the spindle, the parallelism of the guide rail, the flatness of the workbench, etc. will all affect the processing accuracy and smoothness of the thread.

To improve the smoothness of the threads of CNC precision parts, the following aspects can be considered and optimized:

Choose high-quality tools: Using high-quality, sharp tools can reduce cutting forces and cutting heat, and improve the surface roughness and silky feel of the thread.

Adjust appropriate cutting parameters: According to the characteristics of the material and tool, adjust appropriate cutting parameters, such as cutting speed, feed speed, cutting depth, etc., to obtain the best cutting effect.

Reasonable use of coolant: Reasonable use of coolant can effectively lower the cutting temperature and reduce material deformation, thereby improving the accuracy and smoothness of the thread.

Regularly check and adjust equipment: Regularly check and adjust key components such as the spindle, guide rails, and worktables of CNC machine tools to ensure their accuracy and stability, thereby improving the CNC machining accuracy and smoothness of threads.

Improve the skill level of operators: Through training and skill improvement, the skill level of operators can be improved, thereby reducing operational errors and adverse effects, and improving the processing quality and smoothness of threads.

To sum up, in order to improve the smoothness of the threads of CNC precision machining parts, it is necessary to comprehensively consider and optimize many aspects such as tool selection, cutting parameter adjustment, coolant use, equipment inspection and adjustment, and operator skill improvement.