What is CNC Prototype Machining?

Industrial product prototypes often need to be CNC prototypes. CNC prototypes are the first step to verify the feasibility of products. It is the most direct and effective way to find out the defects, deficiencies, and drawbacks of designed products, so as to improve the defects in a targeted manner, eliminating the need for Expensive mold opening costs reduce R&D risks and speed up R&D efficiency. So, what are the CNC prototyping machining methods commonly used in industrial products? The following CNCMF will introduce it to you.

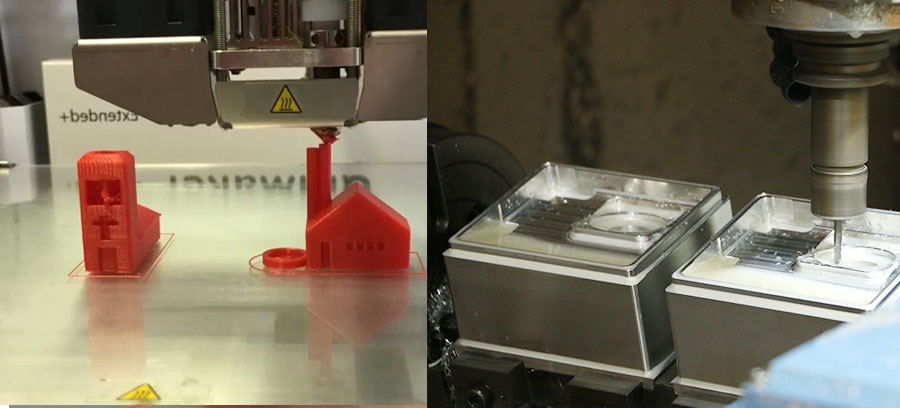

1. 3D Printing

3D printing is now often used for unit price and small batch CNC prototyping machining, which can be used for appearance, structure and performance testing prototypes.

The photosensitive resin selective curing rapid prototyping technology is suitable for the production of small and medium-sized CNC prototype machining parts, and can directly obtain resin or similar engineering plastic products. Photosensitive resin rapid prototyping processing has good surface quality, high system resolution, and high molding accuracy, and is often used for appearance and structural prototypes.

Nylon material has high printing strength and toughness, but the surface has a frosted powder feel. Generally, it is not used for proofing of appearance parts. It is often used to make functional prototypes. Metal materials can also be used for printing, metal CNC prototype machining, and metal printing. The surface is also frosted and powdery.

For a more comprehensive understanding of 3D printing, check out these two articles:

CNC Machining: What is the Difference Between CNC Machining and 3D Printing?

CNC Machining: 7 Benefits of CNC Machining and 3D Printing

2. CNC Machining

CNC machining is widely used in the machining industry, and the technology is relatively mature. For CNC prototyping machining. The effect and accuracy are also very good. The CNC prototype machining method is the first consideration, but the cost is high. There are many materials suitable for CNC prototyping machining, metal parts and plastic parts other than silicone and soft rubber.

3. Vacuum Complex Mold

Duplicate molding refers to using the original template to make a silicone mold in a vacuum state, and pouring it with PU material in a vacuum state, so as to clone a replica that is the same as the original template. It is mainly used for the production of plastic prototypes, and can also be made of silicone or soft rubber prototypes. It is characterized by no mold opening, fast molding speed, and low production cost. One silicone mold can make about 20 plastic parts, which is suitable for small batch customized processing.

How does the CNC Prototype Machining Factory Carry out CNC Prototype Machining?

After handing over the drawings to the CNC prototype machining factory, many customers want to know how the CNC prototype machining factory processes the CNC prototype, so that they can follow up on the CNC prototype model. Let’s talk about the whole process of CNC prototype machining in CNC prototype machining factory.

Consider the industry and prototype data for CNC prototype machining applications

1. Common applications are: digital products, household appliances, medical equipment, aviation models, auto parts, etc.

2. Commonly used CNC prototype machining materials are.

a. Plastic: ABS, PC, acrylic, PMMA, nylon PA, POM, PP, etc.;

b. Metal: aluminum alloy, stainless steel, iron, copper, etc.

The main process of CNC prototype machining in CNC prototype machining factory

1. Drawing review: After receiving the customer’s drawings, conduct a preliminary review of the processed graphics;

2. Disassembly drawing: disassembling the assembly drawing, disassembling and disassembling;

3. Programming: The programming language of CNC is carried out according to the cnc machining technology;

4. CNC machining, machine processing, and removing the excess on the material to obtain the prototype of the product;

5. Manual machining: The hand board just processed from the machine needs some manual processing, because the surface has a sharp edge, etc.;

6. Surface treatment: grinding, painting, polishing, silk screen printing, electroplating, laser engraving, etc.;

7. Finished product assembly;

8. Quality inspection: After the QC department has detected no problems, it can be packaged and shipped;

9. Packing and shipping.

The above is an introduction to the entire process of manufacturing CNC prototype parts in a CNC prototype machining factory. I hope it will be helpful to everyone. CNC prototype machining quality is stable, CNC machining precision is high, and the efficiency of mass production is very high. It is one of the most common processes for making prototype models.