CNC machining is the most important process for making prototype models. With the diversification of prototype processing methods, no one can change the position of CNC in the process of prototype processing.

CNC prototyping parts are generally used to process large prototyping parts with high precision requirements and high appearance requirements.

Why do we often choose CNC prototypes machining ?

Today, I will analyze the characteristics of cnc prototype machining materials, application fields, and the advantages of CNC prototype models.

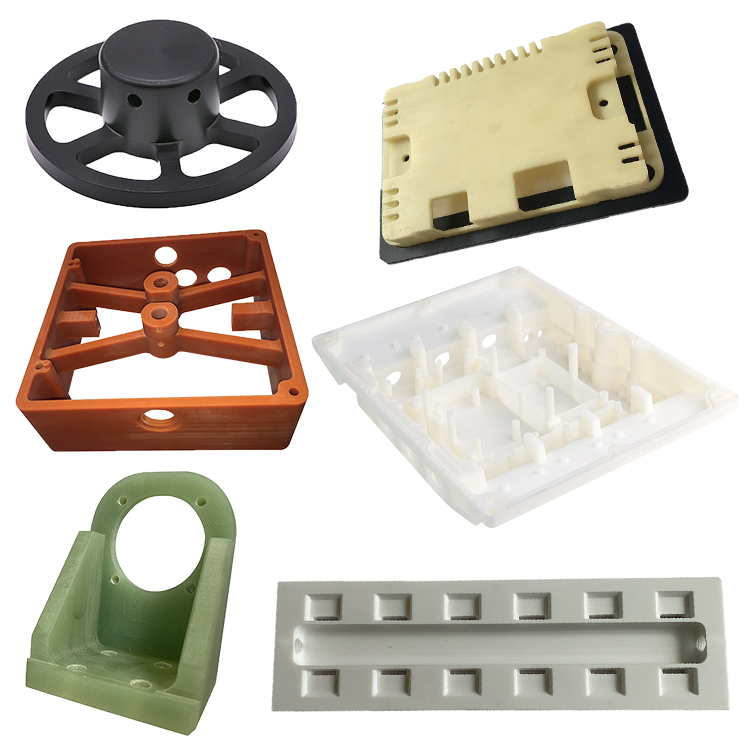

A wide range of cnc prototype machining materials

Machinable materials are ABS, POM, PC, acrylic (transparent material) fiberglass board, PO, Teflon, nylon, bakelite, gray nylon, stainless steel, aluminum alloy, H62 brass, Q235 iron, etc.

The following are some common materials, let’s understand their physical properties and application range together.

1. Nylon CNC prototype machining

Temperature resistance: 60-90℃

Features: Excellent toughness, lubricity, wear resistance, chemical resistance, gas permeability, and oil resistance, non-toxic and easy to color, etc.

It is widely used in medical, aviation, electrical equipment, mechanical equipment, shipbuilding, automobile manufacturing, household appliances, digital products, textile equipment, daily necessities, construction equipment, toys and other fields.

2.Acrylic CNC prototype machining

Temperature resistance: 60-80℃

Features: high transparency

Mostly used in electrical liquid crystal shell prototypes

3. Fiberboard CNC prototype machining

Temperature resistance: 300-500℃

Features: high temperature resistance, non-combustible, anti-corrosion, good heat insulation, sound insulation, high tensile strength, corrosion resistance, aging resistance, good electrical insulation and other outstanding advantages.

Widely used in the electronics industry, electrical (electrical) equipment insulation partitions, insulation pads, transformer insulation parts, motor insulation parts, deflection coil terminal boards, electronic switch insulation boards, etc.

4. Aluminum cnc prototype machining

Temperature resistance: 500-800℃

Features: light metal, low melting point, easy to oxidize, stable chemical properties, good strength

Scope of application: electronic, medical, industrial product shells, etc.

For the physical property analysis of other metal materials, you can enter our website: https://www.machining-custom.com/ and contact us.

CNC prototype machining has a wide range of applications

CNC prototype machining is often used in prototypes for cars, robots, medical, aerospace, design, small household appliances and computer peripheral products, and can also produce functional test standard parts for large complex products, such as air conditioners, monitors, audio, medical equipment, motorcycles, car accessories and other products.

CNC prototyping also has many advantages

1. CNC prototype machining is moderate in cost, extensive in processing materials and in a wide range of applications, which can meet the requirements of different customers for strength, temperature resistance, durability, transparency, etc.

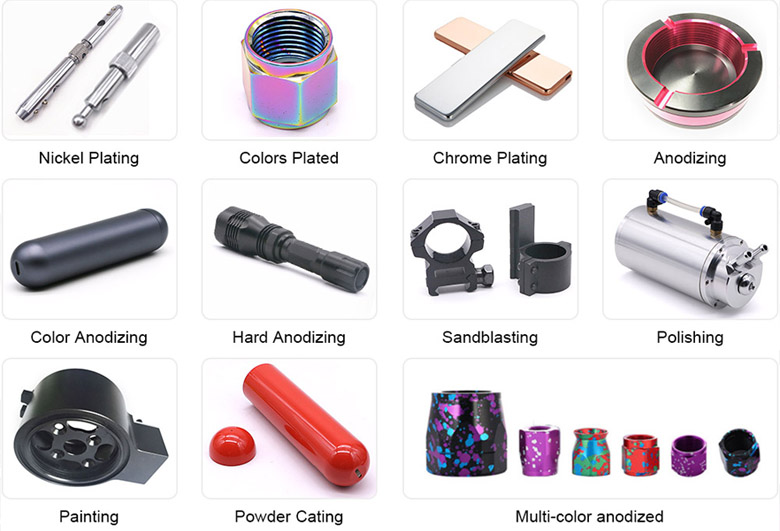

2. The surface treatment methods of cnc prototype machining are diversified, such as grinding, sandblasting, painting, polishing, silk screen printing, electroplating, oxidation, laser engraving, bluing, pvd, etc. The effect can even be compared with the products produced by the mold.

If you don’t know what surface treatment is suitable for your parts, you can click this link to check: https://www.machining-custom.com/aluminum-surface-finishing/, or contact us directly.

、

3. In terms of appearance, assembly and functional verification, it can achieve the purpose of customer planning and verification, and CNC machining can make a workpiece that can truly reflect your planning purposes.

Due to its many advantages, cnc prototype machining has always been the mainstream processing method of modern prototype processing. It is not only suitable for various fields, but also allows customers to achieve the best results for verification purposes.