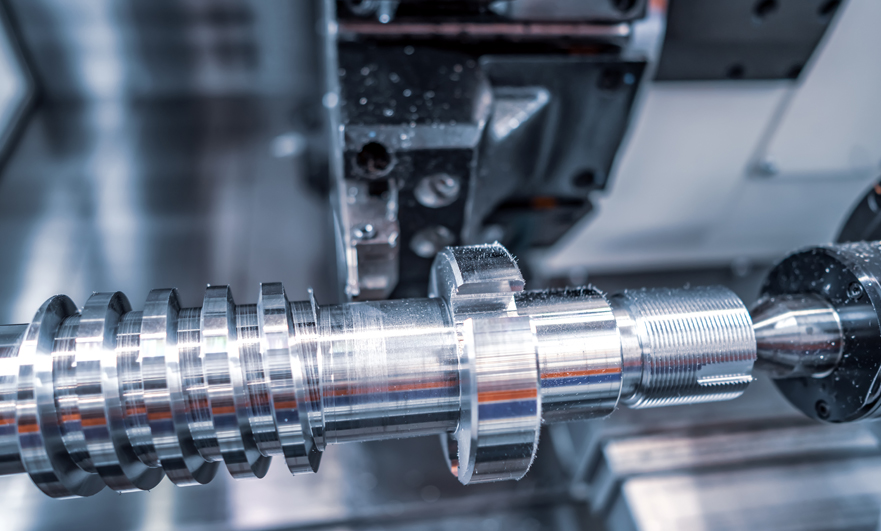

Steel is a common material in CNC machining, but steel is also distinguished, such as stainless steel, carbon steel, and alloy steel.This article introduces what are CNC stainless steel, alloy steel and carbon steel materials? The performance, difference and price of stainless steel, alloy steel and carbon steel.

What are CNC stainless steel, carbon steel, and alloy steel processing materials?

CNC stainless steel: stainless steel is a kind of alloy steel, with rust and corrosion resistance as the main characteristics, and the chromium content is ≥ 10.5%, and the carbon content is ≤ 1.2%. (Note: Mainly used for production pipe lining, onshore and offshore piping systems and heat exchangers.)

Carbon steel: Steel with a carbon content of 0.0218% to 2.11%. Generally, the higher the carbon content of carbon steel, the greater the hardness and strength, but the lower the plasticity. (Note: Widely used in construction, bridges, railways, vehicles, ships, various machinery manufacturing industries, modern petrochemical industry, marine development, etc.)

Alloy steel: An alloying element is usually from 1% to 50%, and the strength, hardness, toughness, corrosion resistance and more characteristics can be enhanced. Alloy steel is generally divided into low alloy steel and high alloy steel. (Note: Alloy steel has become the main force of the industry due to its high cost, multiple applications, and strong mechanical properties. Alloy steel is widely used in applications with significant strength, toughness and corrosion resistance, such as construction and construction, and it is also used in Production of kitchenware, household goods and jewelry.)

Properties of CNC stainless steel, alloy steel and carbon steel

CNC stainless steel: It has good corrosion resistance and high temperature resistance. For example, 304 stainless steel is a very common CNC stainless steel, which is also called 18/8 stainless steel in the industry. Its corrosion resistance is better than 430 stainless iron, corrosion resistance and high temperature resistance, good processing performance, so it is widely used in industry and furniture decoration industry and food and medical industry.

Alloy steel: Manganese, nickel, chromium, cobalt, silicon and other elements can be added, with high hardness, high wear resistance, high toughness, and corrosion resistance. For example, 4140 alloy steel (CR-MO) has tight strength, good wear resistance, good toughness and ductility, and high temperature and wear resistance.

Carbon steel: The performance of carbon steel mainly depends on the carbon content. As the carbon content increases, the strength and hardness of the steel increase, and the ductility, toughness and weldability decrease. For example: #45 steel No. 45 steel is a high-quality carbon structural steel, its strength is 61, with good processing performance and multi-directional processing technology, it has become the most commonly used CNC machining material in steel.

The difference between CNC stainless steel, alloy steel and carbon steel

Corrosion resistance: Both carbon steel and CNC stainless steel contain iron elements. Iron will be oxidized when exposed to the air and rust easily. The addition of other elements to alloy steel greatly improves corrosion resistance, so alloy steel has high corrosion resistance.

Weldability: Carbon steel has low weldability, followed by CNC stainless steel. The highest is alloy steel.

In terms of price: it can be said that the price difference between ordinary carbon steel and ordinary CNC stainless steel. Ordinary carbon steel is about 4,100 per ton, and general stainless steel is about 8,000 per ton. The price ratio is almost 1:2. The price of alloy steel depends on precious metals. Although the price of alloy steel is not fixed, it is still relatively expensive.

Summarize

Considering the price of the material alone, carbon steel is the best, but in terms of practicability and cost, it is still necessary to rely on the use environment to select the required CNC stainless steel material.