Custom CNC Watch Case Manufacturing Process: Maximizing Benefits for Your Customers

In the realm of precision engineering, the process of CNC (Computer Numerical Control) machining has revolutionized the manufacturing landscape. This article delves into the intricate world of custom CNC watch case manufacturing and explores how it can bring substantial benefits to your customers.

Table of Contents

Introduction

Understanding CNC Machining

Customization logo

CNC Watch Case Manufacturing Process

- Design and Modeling

- Material Selection

- CNC Machining Setup

- Precision Machining

- Surface Finishing

Advantages of Custom CNC Watch Case Manufacturing

- Uniqueness and Personalization

- Exceptional Quality and Precision

- Faster Turnaround Time

- Cost-Effectiveness

Ensuring Maximum Benefits for Customers

- Collaborative Design

- Material Guidance

- Iterative Prototyping

- Quality Assurance

Empowering Your Brand Through Customization

Conclusion

Introduction

In the world of horology, where intricacy and elegance converge, the advent of CNC machining has redefined the way watch components are crafted. This article sheds light on the art of custom CNC watch case manufacturing and its potential to elevate customer satisfaction to new heights.

Understanding CNC Machining

CNC machining represents a pinnacle of precision manufacturing, where computer-controlled machines meticulously carve out intricate designs from raw materials. This technology surpasses traditional methods in its ability to achieve unparalleled accuracy, consistency, and complexity.

Custom Logo

Customization has become a hallmark of the modern consumer experience. When applied to CNC watch case manufacturing, it allows customers to print their own unique logo on the watch, making it an expression of personal style.

CNC Watch Case Manufacturing Process

Design and Prototyping: From Concept to Reality

CNC watch cases start with a collaborative design process. Work with designers and engineers to bring your vision to life. Through prototyping, which skilled designers turn into a digital model, you can intuitively understand how a case will look and feel before production. We’ll guide you through design choices that optimize form and function, ensuring that every silhouette and size fits perfectly Meet expectations.

Material Selection: Balancing Appearance and Function

The choice of material profoundly affects the aesthetics and durability of the final product. The foundation of your CNC watch case lies in the choice of material. When choosing a material such as stainless steel, titanium or a precious metal such as gold, consider factors such as durability, aesthetics and cost. Our experts will help you select the ideal material to meet your vision while maintaining structural integrity.

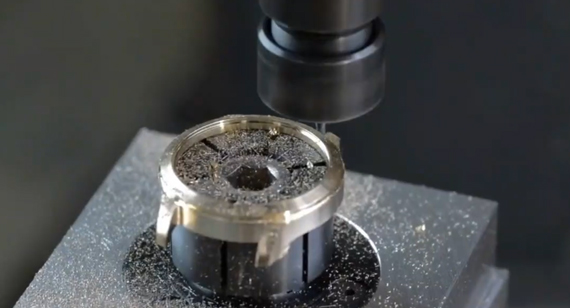

CNC Machining Setup

Once the design and materials were finalized, the CNC machine was installed. The digital model guides the movement of the machine and the preliminary shaping of the case begins.

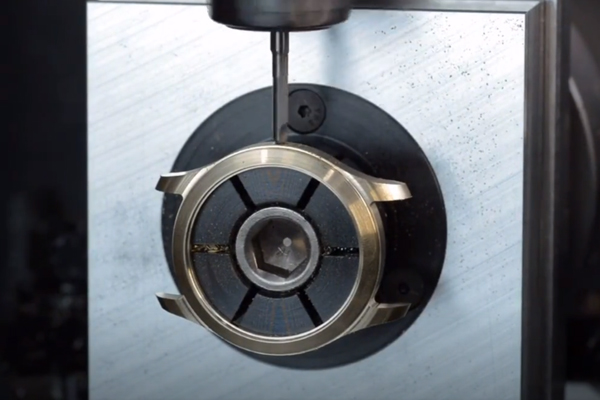

Precision CNC Machining: Turning Ideas into Precision

At this stage, the CNC machine uses its tool arsenal to perform intricate carvings on the exterior and interior of the case. The precision achieved is astonishing, resulting in the perfect fit of the internal components. At the heart of the process lies CNC machining, which ensures the precision of the case. Our experts demystify the machining process, giving you insight into how your designs become tangible reality.

Surface Finishing: enhancing the aesthetic

Surface finish determines the tactile and visual appeal of a case. Various techniques such as polishing, brushing or sandblasting are used to achieve the desired appearance texture and luster. We’ll discuss the possibilities of finishes, enabling you to make a choice that matches the look you want.

Quality Assurance: Ensuring Excellence

Every step has undergone strict quality checks to ensure that the case is flawless. We detail the quality assurance measures taken to ensure your case exceeds expectations.

Advantages of Custom CNC Watch Case Manufacturing

Uniqueness and Personalization

Every individual has a distinct style, and custom CNC watch cases cater to this uniqueness. Customers receive a timepiece that resonates with their personality, setting them apart from mass-produced options.

Exceptional Quality and Precision

CNC machining leaves no room for human error. The watch cases exhibit impeccable craftsmanship and mechanical precision, ensuring flawless functionality and longevity.

Faster Turnaround Time

Traditional manufacturing methods can be time-consuming. CNC machining expedites the process, enabling customers to enjoy their customized timepieces in a shorter timeframe.

Cost-Effectiveness

While the initial perception might lean towards higher costs for customization, CNC machining optimizes resource utilization, making customization surprisingly affordable.

Ensuring Maximum Benefits for Customers

Collaborative Design

Engaging customers in the design phase fosters a sense of ownership. Manufacturers listen to preferences and provide insights, resulting in a design that marries aesthetics with practicality.

Material Guidance

Materials are the building blocks of quality. By guiding customers in material selection, manufacturers ensure the final product aligns with expectations of both aesthetics and durability.

Iterative Prototyping

Prototyping allows customers to visualize the final product. Feedback-driven iterations fine-tune the design, leaving no room for dissatisfaction.

Quality Assurance

Rigorous quality checks guarantee that each watch case leaving the manufacturing facility meets the highest standards, translating to lasting satisfaction for customers.

Empowering Your Brand Through Customization

Custom CNC watch case manufacturing isn’t just about creating timepieces; it’s about crafting an experience. By offering customization, brands establish emotional connections with customers, fostering brand loyalty.

Conclusion

In the world of watch aficionados, the allure of a custom timepiece resonates deeply. Custom CNC watch case manufacturing emerges as a bridge between individuality and precision engineering. As brands embrace this technology, they open avenues for customers to be co-creators of their cherished timekeeping companions.

FAQs

Q: How long does the custom CNC watch case manufacturing process typically take?

A: The duration varies depending on design complexity, materials, and finishing options. However, it’s often faster than traditional methods.

Q: Are there limitations to design possibilities in custom CNC watch cases?

A: The flexibility of CNC machining allows for intricate and diverse designs, but certain structural considerations might apply.

Q: Can I provide my own design for a custom watch case?

A: Absolutely! Manufacturers welcome customer-designed concepts for a truly personalized experience.

Q: Is custom CNC watch case manufacturing environmentally friendly?

A: Yes, CNC machining produces less waste and utilizes materials efficiently, making it a greener option compared to some traditional methods.

Q: How does customization impact the resale value of a watch?

A: Customization can enhance the uniqueness of a watch, potentially increasing its appeal to collectors and enthusiasts.

In conclusion, the journey of custom CNC watch case manufacturing merges artistry with precision, creating timepieces that not only tell time but also stories. This innovative approach empowers customers to define their horological narratives while enjoying the perks of superior craftsmanship and exclusivity. Embrace the era of bespoke watchmaking and craft timepieces that transcend generations.