CNC Machining Service

Want to shorten the production cycle and reduce the cost of CNC machining parts? CNC machining services combined with a number of advanced technologies can simplify the manufacturing process, speed up the mass production of CNC machined parts, and achieve higher precision. CNCMF can provide fast online CNC machining services according to customer requirements. Send us your CAD files or inquiries, and we will provide a fast, free CNC machining quotation for the required CNC machining parts. Let your CNC machined parts enter the processing state in the shortest time.

China Custom CNC Machining Parts Manufacturer—Precision CNC Machining Service

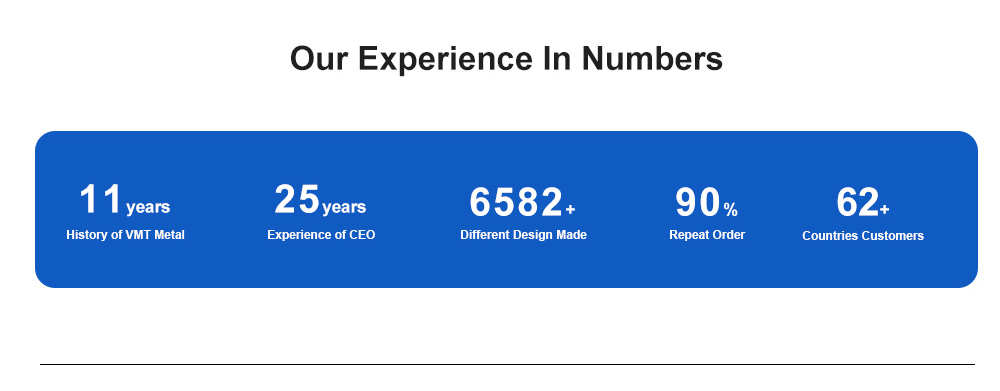

As a successful CNC machining manufacturer, CNCMF has been focusing on OEM metal CNC machining and manufacturing services, customized CNC machining parts production and fast CNC machining services for more than 11 years in China, and has always maintained the highest standards of precision CNC machining parts manufacturing and delivery speed And reliable quality. With high-level technology and efficient equipment, as well as a rigorous attitude, we have passed the ISO9001:2015 quality certification.

CNCMF CNC milling services, CNC turning services, CNC turning and milling combined machining, 3/4/5 axis machining, gear machining services, China customized CNC machining parts services, small parts machining, etc. CNCMF can process more than 40 materials, and CNC machined parts are widely used in various industries.

CNCMF CNC Machining Service Capability

As one of the fastest-growing precision CNC machining service providers in China, CNCMF’s CNC machining capabilities can meet your needs for CNC machining parts, from rapid prototyping to precision CNC machining of parts and mold processing, and end-use production.

CNC Milling Service: generally considered as the most common machining process, it refers to the use of a CNC milling cutter to make circular motions to machine a milled part with a certain shape and detail on a stationary CNC machined part, including slots, holes, and notches , Grooves, etc.

CNC Turning Services: mainly use turning tools to turn CNC machining parts. Lathes are mainly used for machining shafts, discs, sleeves and other CNC machining parts with rotating surfaces. They are the most widely used type of machine tool processing in machinery manufacturing and repair factories.

CNC Drilling Service: the cutting process of fixing the workpiece, aligning the center of the tool with the center of the hole and rotating to produce a round hole, can be completed on a lathe and a milling machine.

CNC Turning and Milling Compound Machining Service: a composite processing technology in which the tool and the workpiece rotate at the same time, through the design of multiple tasks to produce complex curves or special-shaped parts.

Wire Cutting: EDM CNC machined parts from prototype to full-scale production, with strict tolerances and complex structures.

CNCMF CNC Machining Service Materials

CNCMF CNC machining service manufacturer, in order to deliver in time, we have stocked some common metals, plastics and other types of materials, such as steel, aluminum, stainless steel, copper, bronze and brass.

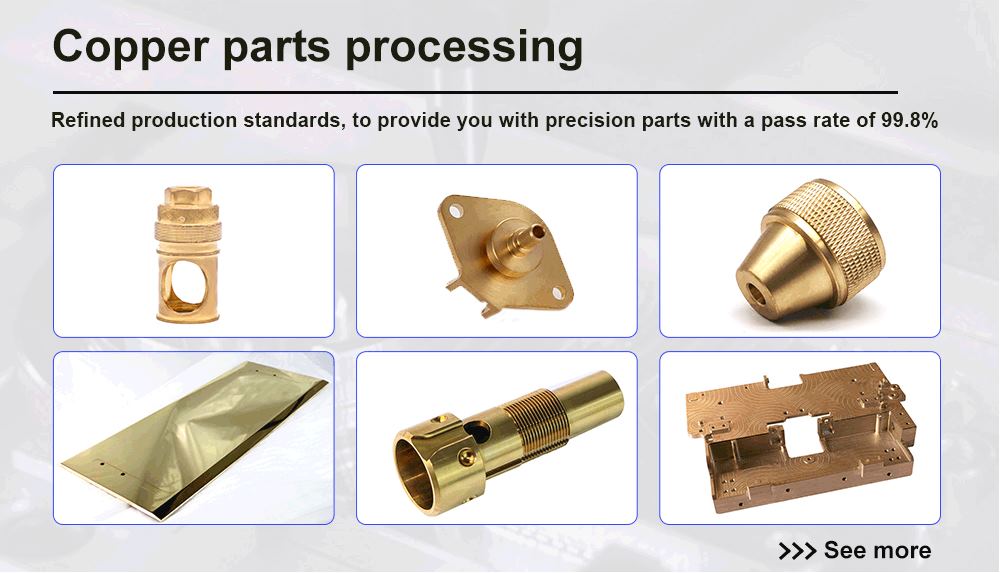

Copper: brass 360, 101 copper, 110 copper, 932 bronze, etc.

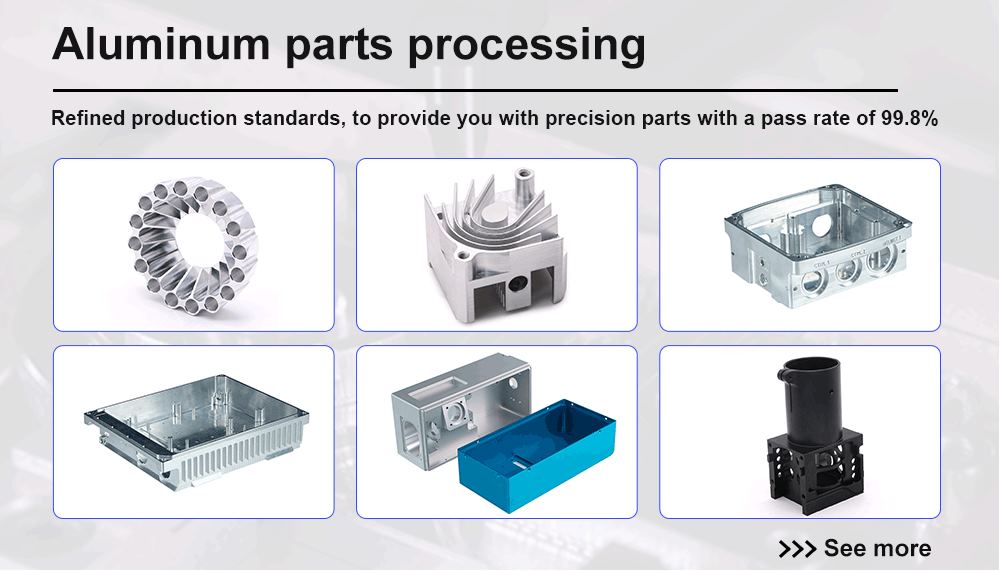

Aluminum: 2024, 5083, 6061, 6063, 7050, 7075, etc.

Stainless steel: 303, 304, 410, 17-4, 2205 duplex, 440C, 420, 316, 904L, etc.

Steel: 4140, 4130, A36, 1018, etc.

Titanium: Grade 2, Grade 5, etc.

CNCMF CNC Machining Surface Treatment

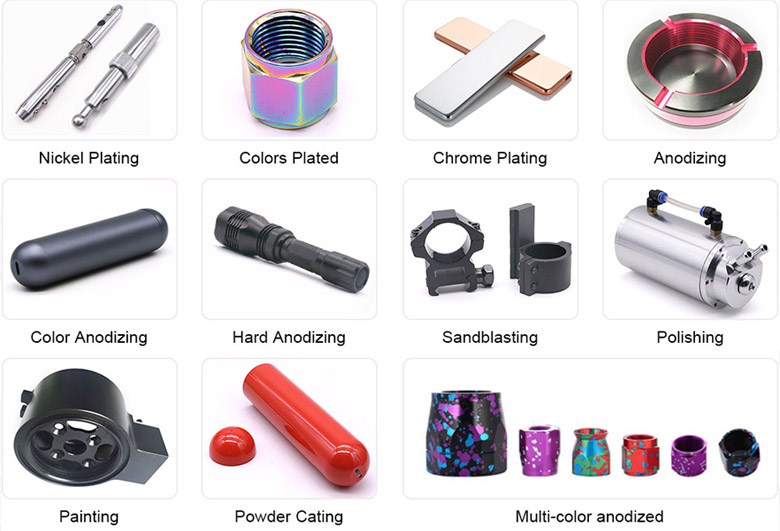

CNCMF CNC machining parts service manufacturers have a variety of metal surface treatment services to improve the appearance, surface finish, corrosion resistance and other properties of CNC machining parts.

Anodizing: An electrolytic passivation process that forms a thin oxide film on the outside of the CNC machined parts to increase the thickness of the natural oxide layer and protect the metal. It has higher corrosion resistance and wear resistance.

Electroplating: The process of using electric current to reduce the dissolved metal cations so that they form a thin coherent metal coating on the electrode to change the characteristics of the processed metal surface or increase the thickness of parts that are too small.

Powder coating: a functional and decorative finish, applied in the form of a free-flowing dry powder, electrostatically, and then heated and cured to form a harder finish that is stronger than traditional coatings. Main applications include household appliances, aluminum profiles, drum hardware, automotive, motorcycle and bicycle parts.

Polishing: also known as polishing, is a process of rubbing the surface of a part or using chemical action to produce a smooth and shiny surface, so that the surface can obtain significant specular reflection or reduce the diffuse reflection of certain materials.

Black oxidation: also known as blackening, gun bluing or thermal blackening, a chemical process that forms black conversion coatings on stainless steel, copper and copper-based alloys, zinc, powdered metals, silver solders, and ferrous metal materials. Improve corrosion resistance and minimize light reflection.

Conversion coating: Also known as chromate conversion coating, it is used to convert metal into a protective layer through a chemical or electrochemical process. It is mainly used as a corrosion inhibitor, decorative finish or to maintain conductivity.

Bead spraying: The process of removing deposits on the surface of CNC machined parts by applying fine glass beads under high pressure without damaging the surface.

Sandblasting: The process or operation of using sandblasting equipment (such as a pneumatic system) to push the abrasive stream composed of high-speed sand particles to the metal surface under high pressure to remove surface contaminants, clean the metal or increase the texture, and then change the CNC machining The smoothness or roughness of the surface of the part.

In addition, we have more surface treatment processes, such as PVD, etching and dozens of surface treatment processes for you to choose from.

CNCMF’s CNC Machining Service Advantages

With efficient CNC machining services, mass production, and fast proofing services, simple parts can be proofed in one day, and complex parts can be proofed in as fast as 3 days. 99.65% on-time delivery rate.

A variety of machining materials are selected to meet specific attributes. Quick and free CNC machining service quotation within 24 hours after inquiry.

DFM manufacturing experience, are you looking for a high-quality CNC machining service manufacturer? Our low-cost custom CNC machining service will review the design, establish your quotation, evaluate the cost and put your non-metal or metal manufactured parts into production in an orderly and efficient manner.

Application of CNCMF CNC Machining Service

CNC machined parts are everywhere, they may be an important part of your car, or they can play an important role in your electrical equipment. CNCMF is a precision metal parts CNC machining service manufacturer. It has been engaged in the hardware industry for 11 years. Our business covers 62 countries around the world, covering military, medical, semiconductor, automotive and other fields.

Electronics industry: electronic connectors, metal mobile phone frames, Bluetooth headset shells, etc.

Medical industry: precision rotating shafts, medical stents, precision medical metal aluminum parts, etc.

Automobile industry: AN oil-cooled joints, aluminum metal auto parts, etc.

Industrial industry: industrial connectors, titanium alloy manufacturing parts, etc.

Military industry: military application components, precision communication accessories, etc.

Aerospace industry: UAV rotating shaft, UAV panel, etc.