What is aluminum alloy die casting?

Aluminum alloy die casting refers to the method in which liquid aluminum alloy flows from the pressure chamber into the mold cavity at an extremely fast speed under high temperature and high pressure, and forms a casting after cooling. Due to the advantages of high dimensional accuracy, good mechanical properties, and high production efficiency, die castings have broad application prospects in the fields of automobiles, motorcycles, internal combustion engines, electronics, instruments, and aerospace. The liquid metal flows from the pressure chamber into the mold cavity at an extremely fast speed under high temperature and high pressure. The molten metal is easily involved in gas during the flow process and the temperature distribution is unbalanced during the casting process, resulting in castings. Defects such as air holes, shrinkage cavities, burns, and cold shuts, etc., this paper discusses solutions to the defects caused by die-casting production.

The technology of aluminum alloy die-casting is a special casting method with less and no cutting, which is developing rapidly in modern metal processing technology. It is the process of filling the mold with molten metal at high pressure and high speed, and crystallizing and solidifying under high pressure to form a casting.

This process is formed under high temperature and pressure, which is prone to defects. Now we analyze the common defects in die casting and discuss the solutions.

1. Cold insulation problem

Appearance characteristics: The appearance of die castings has obvious and irregular sunken linear texture (there are two kinds of penetration and non-penetration). The shape is small and narrow, and sometimes the edges are smooth, which may develop under the action of external force.

Reason: The temperature of two or more strands of molten soup is too low, and there are traces when they are stacked. Metal bonding is weak. Pouring temperature or mold temperature is too low. The fluidity of molten soup is poor. The sprue is in the wrong position or the flow line is too long. Low filling speed and poor venting. The injection ratio is lower than the pressure. The molten metal does not flow smoothly in the cavity.

Solution: Properly increase the pouring temperature, control it at 640°-680°C (can be adjusted according to the product and aluminum material), and appropriately increase the mold temperature. Increase the injection specific pressure and shorten the filling time. During the debugging process of the die-casting machine, the speed of the punch should be appropriately increased, and the cross-sectional area of the inner gate should be increased at the same time. Improve exhaust filling conditions. Choose a suitable alloy to improve the fluidity of the molten metal. Improve the smooth flow of molten metal in the cavity. Check whether the wall thickness is too thin (design or manufacture), the thinner area should be directly filled. Check that the shape is not easy to fill. If the distance is too far, closed areas (such as fins, protrusions), blocked areas, and fillets are too small, it is not easy to fill. If this happens, you can change and increase the runner to supplement the cold barrier area. And watch for rib spots or cold spots. Increase the slag bag in the cold insulation area. Increased exhaust or vacuum may help.

2. Crack problem

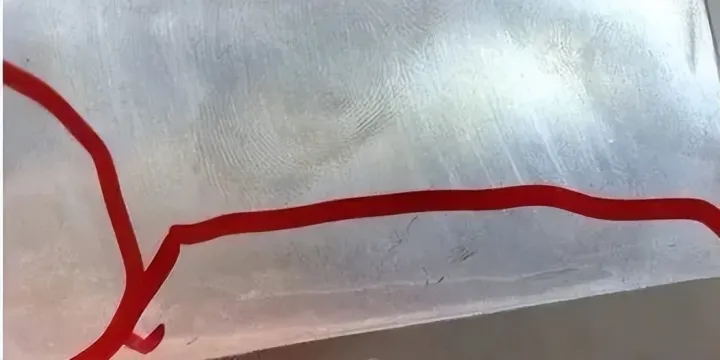

Appearance features: The appearance of die castings has linear or irregular narrow textures, which tend to develop under the action of external forces. Cracks include: cold cracks and hot cracks. Cold cracking: The metal at the crack is not oxidized. Hot cracking: The metal is oxidized at the crack.

Reason: There is a problem with the alloy composition, which reduces the plasticity of the alloy. Mold temperature is too low. Where there is a drastic change in the wall thickness of the casting, the shrinkage is hindered and the shrinkage stress occurs. The mold stay time is too long and the stress is large. The force is uneven when ejecting.

Solution: Correctly control the alloy composition. Change the casting layout, increase the fillet, increase the demoulding slope, reduce the wall thickness difference, change or increase the ejector pin, so that the ejection force is even. Check whether the mold is dislocated or deformed, and shorten the time of mold opening or core pulling. Control mold temperature (mold working temperature 130°C-200°C). Increase or decrease mold clamping time.

3. Pore problem

Appearance features: pinhole-shaped or slightly larger pores occur in the casting, and the casting is exposed after CNC machining; or the pores are in places where the sealing requirements are high. After the leak tester is pressurized, leakage often occurs. The surface of the pores is generally smooth, and they are round or oval. Sometimes they exist in isolation, and sometimes they are clustered together. They can be divided into hydrogen pores and entrained pores.

Reasons: (1) Formation of hydrogen pores: The hydrogen pores are tiny, needle-shaped, and evenly distributed, and can only be observed after the surface of the part is processed. Due to the thin wall of die castings and the rapid solidification of molten metal, hydrogen pores are sometimes difficult to observe with the naked eye. Water vapor is the most important source of hydrogen, which may come from torch gas, smelting tools, aluminum ingots/recycled parts, oil-contaminated machining shavings and wet refining agents, etc.

(2) Formation of air-entrained pores: air-entrained pores are round, clean inside, smooth and shiny on the surface, sometimes the entrained air exists alone, and sometimes clustered together. Air entrainment generally occurs in the punch system, runner system and cavity.

Solutions: (1) Solutions to the formation of hydrogen pores: use GBF degassing and slag removal device for refining; check whether the release agent is sprayed too much and whether the concentration of the release agent is in an appropriate range.

(2) The solution to the formation of air-entrapped pores: choose an appropriate slow speed during the debugging of the die-casting machine, and check whether the turning of the runner is smooth and whether the cross-sectional area is gradually decreasing. Check whether the exhaust area is large enough, whether it is blocked, whether the position is located at the last filling place, and improve the exhaust. Whether the mold temperature is too low. The method of vacuuming can effectively exhaust the gas entering the cavity.

4. The problem of shrinkage cavity

Appearance features: There are sunken pores visible to the naked eye at the lower part of the casting surface.

Reason: After the metal melt is filled, the liquid phase is transformed into a solid phase, and shrinkage will occur. Die castings are cooled from the filling to the inside. When the temperature is high and the local wall thickness of the casting is large, the internal cooling is slow, and shrinkage cavity problems will inevitably occur at this time.

Solution: Properly reduce the wall thickness and increase the pressure during the debugging process of the die-casting machine. Control the temperature of the mold to help the department cool down. If the shrinkage cavity is in the direction of the sprue, direct feeding can be performed through a new method. The extrusion process is used to forcibly squeeze and feed the shrinkage cavity in the semi-solid state.

5. Deformation problem

Appearance features: The geometric shape of the die-casting parts does not match the drawings, and the overall or partial deformation causes the dimensional tolerances of key parts of the product to fail to meet the requirements of the drawings.

Reason: poor casting layout design, causing uneven shrinkage. If the mold is opened too early, the casting will not be rigid. Buckle mold deformation. The setting of the ejector rod is unreasonable, and the force is uneven when ejecting. The method of removing the gate is not appropriate. The product will be deformed under the action of external force, such as surface shot blasting, sandblasting, or careless beating, knocking will cause deformation.

Solution: Improve casting layout. Adjust the mold opening time. Reasonably set the position and quantity of ejector pins. Choose a reasonable way to remove the gate. Increase the draft angle to eliminate the position of the strain. Check whether the surface is deformed due to surface shot blasting, sandblasting, or accidental beating and knocking.

6. Burr problem

Appearance characteristics: The appearance of the product produces thin flake excess material. Reason: Insufficient clamping force. The mold is poorly closed. The strength of the mold is insufficient, resulting in subsidence, and the temperature of the molten soup is too high. The mold is not blown clean, and the mold is depressed by the remaining material during the mold closing process.

Solution: Check the clamping force of the machine. Check the clamping condition of the mold and whether the mold is pressed trap. Check whether the mold material meets the requirements. Check whether the casting pressure is too high during the debugging of the die-casting machine. The temperature of the molten soup is controlled at 740·C-780·Co.

7. Mold erosion and cracking problems

Appearance features: Mold burns, serious erosion, and the product has traces of raised or sunken hairlines, which cannot expand and extend as the number of die-casting increases.

Reason: The filling speed is too high, impacting the mold, causing mold damage and cracking.

Solution: check the injection ratio, the cross-sectional area of the punch and the cross-sectional area of the ingate are generally controlled at 13-16 times, if it is too high, the width and thickness of the ingate must be increased. Check whether the mold material is in compliance with the regulations. Check whether the mold has reached the design life. If it arrives, the mold will be replaced. In addition, the coating process can be used to make special treatment for the severely eroded parts of the mold. During the debugging process of the die casting machine, the high speed of the punch should be appropriately reduced.

8. Ripple problem

Appearance features: The local structure of the product is different and there are obvious ripples.

Reason: The first layer of melting heat is rapidly cooled on the surface, and the second layer of molten soup cannot melt the first layer.However, there is enough integration to make the organization different.

Solution: Improve the filling mode and shorten the filling time.

9. Sticky mold problem

Appearance features: The whole or part of the product sticks in the mold cavity and cannot be released, which is divided into sticky movable mold and sticky fixed mold.

Reasons: The slope of the product is not enough, there is a problem with the ejection, and the local temperature of the mold is too high.

Solution: increase the draft angle of the product. The mold is newly increased cooling, and the local cooling is increased during the die-casting process.

Add water by spraying to reduce mold temperature. Add ejector pins to the mold. For sticky molds, consider adding a fixed mold ejector mechanism. You can also add undercuts to the moving mold.

10. Carbon accumulation problem

Appearance features: The appearance of die castings shows spots different from the color of the base metal.

Reason: Release agent or other impurities accumulate on the mold.

Solution: reduce the amount of release agent sprayed, increase the mold temperature, choose a suitable release agent, use soft water to dilute the release agent.

11. Peeling problem

Appearance features: Die-casting parts are blackened and peeled off.

Reasons: poor filling mode, resulting in molten soup overlapping, mold deformation, inclusion of oxide layer.

Solution: Switch to high speed early, shorten filling, change filling mode, gate position, gate speed, check whether the mold strength is sufficient. Check for inclusions of oxidation.

12. Under-casting problem

Appearance features: Die castings have insufficient filling or unclear outlines on the surface.

Reasons: Metal liquid absorbs gas, oxidizes inclusions, has high iron content, makes it poor in quality and reduces fluidity. The pouring temperature is low or the mold temperature is low. Injection specific pressure is too low. Too much gas is involved, the back pressure of the cavity becomes high, the filling is hindered, the operation is poor, the paint is sprayed, the injection oil is too much, the paint and the injection oil are accumulated, and the gas cannot be volatilized.

Solution: improve the quality of molten metal, increase the pouring temperature or mold temperature, increase the specific pressure and filling speed of die casting, improve the diversion method of molten metal in the gating system, and add overflow grooves and exhaust grooves in the undercast parts. Correct Die casting operations.

Summarize

Aluminum alloy die-casting is one of the elements of die-casting production. To produce excellent die-casting parts, in addition to reasonable part structure, well-designed die-casting mold and die-casting machine with superior process performance, alloys with good performance are also required.