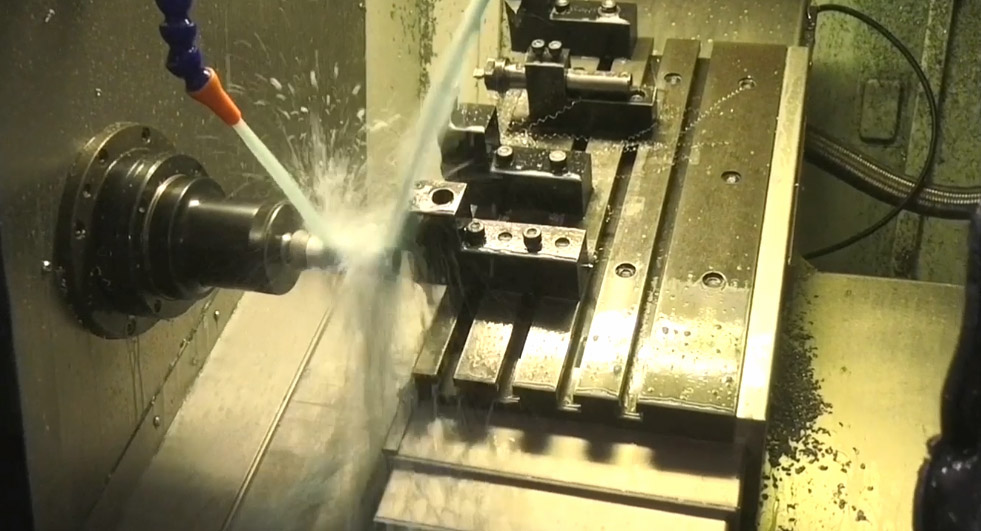

(1) Analysis of OEM custom CNC machining milling parts process

What do we want to machining? ——Analyze the CNC machining milling object.

How to process?-Determine the processing plan.

What tool to choose to complete the CNC machining milling? -Determine the process equipment.

1. Analyze the sample drawing of the part and determine the blank

2. Determine the OEM custom CNC machining milling plan

(a) Determine the machining method.

(b) Determine the machining process and formulate the procedure.

3. Determine the process equipment

(a) Selection of tools.

(b) Design clamping and positioning methods.

4. Determine the machining process parameters and tool path

5. Develop process regulations

(2) CNC milling machining to compile CNC programs

Manual programming: The entire CNC programming process is completed manually. The requirements for programmers are high (not only must be familiar with CNC codes and programming rules, but also have processing technology knowledge and numerical calculation capabilities).

Computer-aided programming: The programmer only needs to send the processing information of the part to the computer in a simpler way according to the requirements of the OEM custom CNC milling machining part drawing and the provisions of the automatic programming system. The computer will automatically write the program, and the programming system can automatically print out the program list and prepare the control medium.

(3) OEM custom CNC machining milling parts, input the program into the CNC system

The compiled numerical control program should be saved in the numerical control system in the form of a text file (ASCⅡ code) so that it can be called during processing. Generally, the editing function provided by the numerical control system can be used to input and store the program, and the communication function of the numerical control system can also be used to directly transfer the numerical control program file to the numerical control system.

(4) CNC milling machining verification and first piece trial cutting

Generally, the program must be checked before the formal machining. The machining center can check the correctness of the machine tool and the motion trajectory by idling, so as to generate the correctness of the program.

(5) Principles of CNC milling machining

CNC machining (drilling and milling machining center) is to first determine the processing technology and process parameters of the part according to the requirements of the drawing, and then write the CNC machining program of the part according to the programming manual, and then manually input or computer input to the CNC system of the CNC machine tool. In order to control the relative movement of the CNC machine tool and the workpiece, so as to complete the machining of the part.

(6) OEM custom CNC milling machining parts

First determine the processing technology of the part according to the requirements of the drawing, formulate the process card, and then write the CNC machining program of the part according to the programming requirements, and then enter the CNC system to verify the correctness and perform the tool setting operation, and perform the first piece of trial cutting. According to the results of the trial cutting, the processing technology of the parts is determined, and the finished parts are finally machined.

Essential skills for CNC milling (turning and milling machining center):

1. Correctly identify pictures

Able to understand three views and design the required fixtures, tools and processing technology according to the drawings.

2. Familiar with the basic knowledge of machining

Familiar with the processing materials and the materials of the tools used.

3. Familiar with CNC technology, able to operate machining center machine tools proficiently

Different systems used by OEM custom CNC machining milling machine tools have different operating functions and operating panel designs.