In the world of CNC machining and manufacturing, it’s essential to stay updated with the latest processes and techniques. One such technique that has gained prominence is hard coating anodizing, specifically focusing on aluminum. This quick guide will provide you with insights into aluminum hard anodization, its benefits, and its applications.

What is Hard Coating Anodizing?

Hard coating anodizing, also known as hard anodization, is an electrochemical process used to thicken the natural oxide layer on the surface of aluminum. This results in a durable and corrosion-resistant coating that enhances the material’s properties. It’s particularly beneficial for industries where aluminum components require increased hardness and wear resistance.

What is the Purpose of Hard Coat Anodizing?

The purpose of hard coating anodization is to enhance the properties of aluminum and other metals for various industrial applications. This process serves several essential purposes:

Increased Hardness: Hard anodization significantly increases the surface hardness of aluminum. This hardness provides resistance to wear, abrasion, and damage, making it suitable for components exposed to harsh conditions.

Corrosion Resistance: Anodizing forms a thick, protective oxide layer on the aluminum’s surface, making it highly resistant to corrosion from environmental factors like moisture and chemicals. This corrosion resistance is vital for outdoor and marine applications.

Improved Lubrication: Anodized surfaces have excellent lubricity, reducing friction between moving parts. This property is essential in machinery and automotive components, where reduced friction can lead to improved efficiency and longevity.

Electrical Insulation: Anodized aluminum is an excellent electrical insulator. This makes it valuable in electronic components, electrical enclosures, and applications where electrical conductivity needs to be minimized.

Aesthetic Appeal: Hard anodization can also be used for decorative purposes. It allows for the incorporation of various colors and finishes, enhancing the visual appeal of aluminum components.

In summary, hard coating anodization aims to make aluminum and other metals more durable, corrosion-resistant, and versatile for a wide range of industrial uses.

What Metal Materials is Hard Coat Oxidation Used For?

Hard coating anodization is primarily used for aluminum and its alloys. While it is most commonly associated with aluminum, the process can also be applied to other non-ferrous metals, including:

Titanium: Anodization enhances titanium’s corrosion resistance and can create colorful surface finishes. This makes it useful in aerospace, medical, and jewelry applications.

Magnesium: Anodized magnesium improves its corrosion resistance, making it suitable for lightweight structural components in aerospace and automotive industries.

Zinc: Zinc anodization is used to provide corrosion protection and improve paint adhesion on zinc-coated steel and zinc-aluminum alloys.

Niobium: Anodizing niobium creates vibrant, long-lasting colors for jewelry and decorative items. It also improves corrosion resistance.

Tantalum: Tantalum anodization enhances corrosion resistance and is used in the medical and electronics industries for its biocompatibility and electrical properties.

Magnesium Alloys: Anodizing can be applied to magnesium alloys to improve their corrosion resistance and surface hardness.

Other Non-Ferrous Alloys: While less common, anodization can be adapted to some other non-ferrous alloys based on their specific compositions and properties.

However, it’s important to note that the process and its effectiveness may vary depending on the specific metal or alloy being anodized. The choice of the metal and the anodization process parameters will determine the final properties and applications of the treated material.

Aluminum CNC Machined Parts Hard Coating Anodizing Process

The hard coating anodization process for aluminum typically follows a specific series of steps. Here’s an overview of the process:

Preparation:

The aluminum part or component is thoroughly cleaned to remove any contaminants, such as grease, oils, or dirt. Cleaning is crucial to ensure a uniform and effective anodized layer.

Etching (Optional):

In some cases, the aluminum surface is etched using an alkaline solution or an acid-based etchant. Etching creates a more textured surface, which can improve the adhesion of the anodized layer.

Rinsing:

After cleaning and, if applicable, etching, the aluminum part is rinsed to remove any residual chemicals.

Anodizing Bath:

The aluminum piece is immersed in an electrolytic solution, typically sulfuric acid. The aluminum part serves as the anode in an electrical circuit.

Anodization:

An electrical current is applied, passing through the aluminum and causing oxidation to occur on the surface. This results in the formation of a porous layer of aluminum oxide.

Dyeing (Optional):

If color is desired, the anodized aluminum can be immersed in a dye bath after anodization. The porous structure of the anodized layer allows it to absorb the dye, creating colored finishes.

Sealing:

The anodized aluminum is then sealed, often in a boiling deionized water bath. This step closes the pores in the anodized layer, further enhancing its corrosion resistance and durability.

Rinsing and Drying:

The sealed aluminum part is thoroughly rinsed to remove any residual chemicals and then dried.

Quality Control:

The anodized part undergoes quality control checks to ensure that the thickness and quality of the anodized layer meet the specified requirements.

Finishing (Optional):

Depending on the application, additional finishing steps such as machining, polishing, or coating may be performed after anodization.

The result is an aluminum component with a hard, durable, and corrosion-resistant surface layer. The thickness of the anodized layer can be controlled by adjusting the anodization time and voltage, allowing for customization based on specific application requirements.

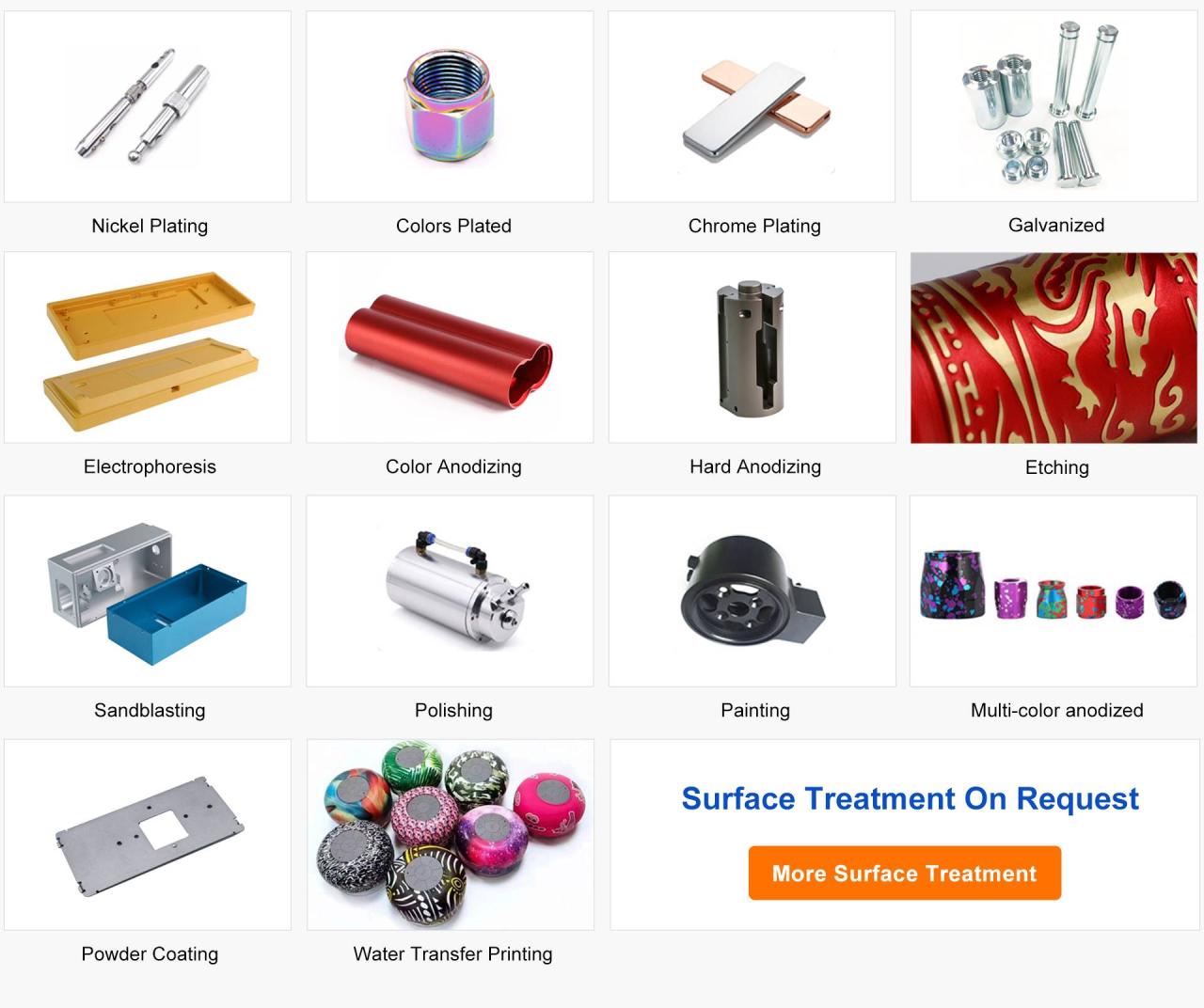

Hard Coat Anodized Appearance: Presented in 8 Categories

Hard coating anodization of aluminum can produce various types of appearances or finishes based on the specific requirements of the application. Here are some common categories of appearances:

Natural Finish:

In its natural state, anodized aluminum has a matte, slightly textured appearance. It typically has a light gray to silver color. This finish is often used when the primary goal is to enhance the metal’s properties without altering its appearance significantly.

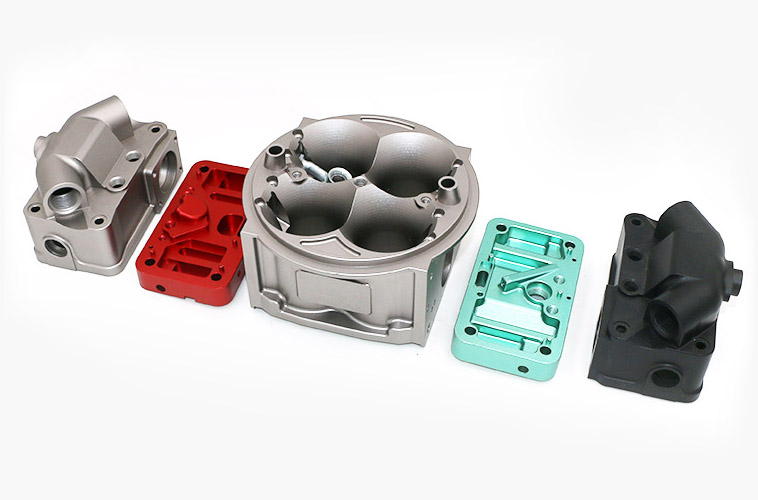

Color Anodizing:

Anodized aluminum can be dyed to achieve a wide range of colors. The porous structure of the anodized layer allows it to absorb dyes effectively. This is commonly used for decorative and aesthetic purposes in various industries, including consumer electronics, automotive, and architecture.

Bright or Mirror Finish:

Through additional polishing or mechanical finishing processes after anodization, aluminum can achieve a bright or mirror-like finish. This finish is highly reflective and is often used in decorative applications, such as architectural elements and automotive trim.

Satin Finish:

A satin finish is achieved by brushing the anodized surface with abrasive materials. This results in a smooth, semi-reflective appearance with fine, parallel lines. Satin finishes are common in architectural and furniture applications.

Textured Finish:

Textured finishes are created by various methods, including bead blasting or chemical etching. These finishes give the aluminum surface a unique texture, which can be both decorative and functional, offering improved grip in certain applications.

Matte Finish:

A matte finish is achieved by carefully controlling the anodization process parameters to produce a uniform, non-reflective surface. This finish is often preferred for industrial and outdoor applications, as it reduces glare and provides a subdued appearance.

Custom or Artistic Finishes:

Anodized aluminum can be further customized with artistic designs or patterns using techniques like laser engraving or masking. This allows for unique and personalized appearances in various products, including jewelry and signage.

Hard Black Anodizing:

A specialized form of anodization can produce a hard, deep black finish on aluminum. This finish is highly durable and is often used in applications where aesthetics and corrosion resistance are essential, such as firearms and sports equipment.

The choice of finish depends on the intended use, aesthetic preferences, and functional requirements of the aluminum component. Each type of finish offers unique benefits and can be tailored to meet specific design and performance criteria.

What is the Thickness of Hard Anodizing?

The thickness of hard coating anodization, also known as hard anodization, can vary depending on the specific application and requirements. However, typically, the hard anodized layer is relatively thick compared to standard anodization processes.

The thickness of a hard anodized layer typically ranges from 25 to 100 microns (µm) or more. This substantial thickness is necessary to achieve the desired level of hardness and wear resistance. In some cases, for extremely demanding applications, the anodized layer may exceed 100 microns in thickness.

It’s important to note that the thickness can be controlled to some extent by adjusting the parameters of the anodization process, including the duration and voltage. The specific thickness chosen will depend on the mechanical and functional requirements of the component being treated.

How hard can hard anodized aluminum be?

Hard coating anodization, also known as hard anodization, can significantly increase the hardness of aluminum surfaces. The hardness achieved through hard anodization depends on various factors, including the specific process parameters and the type of aluminum alloy being treated.

In general, hard anodization can result in a hardness of approximately 40 to 70 on the Rockwell C scale (HRC). However, in some cases, with specialized processes and specific alloys, hardness values can exceed this range.

It’s important to note that the hardness achieved through hard anodization is substantially higher than that of untreated aluminum, which typically falls in the range of 15 to 30 HRC. This increased hardness is one of the primary reasons why hard anodization is chosen for applications where wear resistance and durability are essential, such as in the aerospace, automotive, and industrial machinery industries.

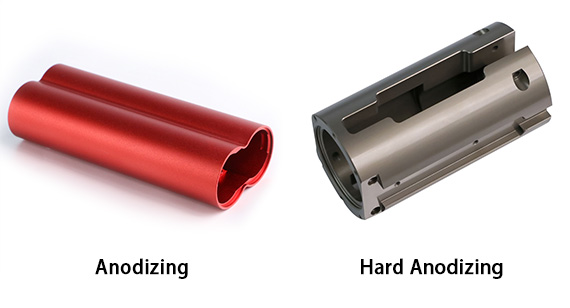

Aluminum Hardcoat Anodizing vs. Anodizing: What’s the Difference?

Certainly, there are differences between hard coating anodization (hard anodization) and conventional anodization processes for aluminum. Additionally, aluminum anodization can be categorized into three main types. Let’s explore these distinctions:

Differences between Hard Coating Anodization and Conventional Anodization:

1. Purpose and Properties:

Aluminum Hard Coating (Hard Anodization):

Purpose: The primary goal of hard coating anodization is to significantly increase the surface hardness and wear resistance of aluminum components.

Properties: It produces a dense, thick, and highly durable oxide layer that enhances hardness and provides excellent resistance to wear and abrasion. This makes it suitable for applications where mechanical durability is essential.

Conventional Anodization (Sulfuric Acid Anodizing):

Purpose: Conventional anodization aims to improve the corrosion resistance of aluminum and, in some cases, provide decorative or colored finishes.

Properties: It results in a thinner and less dense oxide layer compared to hard coating anodization. While it does offer corrosion protection and can achieve various colors through dyeing, its primary focus is not on hardness or wear resistance.

2. Layer Thickness:

Aluminum Hard Coating (Hard Anodization):

The oxide layer formed in hard coating anodization is relatively thick, typically ranging from 25 to 100 microns or more. This substantial thickness is essential for achieving the desired hardness and wear resistance.

Conventional Anodization (Sulfuric Acid Anodizing):

The oxide layer generated through conventional anodization is thinner, generally in the range of 5 to 25 microns. This thickness primarily provides corrosion protection and may not significantly increase hardness.

3. Electrolyte and Voltage:

Aluminum Hard Coating (Hard Anodization):

Hard anodization often uses a more concentrated sulfuric acid electrolyte and higher voltages compared to conventional anodization. These conditions are necessary to achieve the desired thickness and hardness of the oxide layer.

Conventional Anodization (Sulfuric Acid Anodizing):

Conventional anodization typically employs a dilute sulfuric acid electrolyte and lower voltages, suitable for achieving corrosion protection and colored finishes.

4. Sealing:

Aluminum Hard Coating (Hard Anodization):

Sealing: Hard anodization typically involves sealing the anodized layer through methods like boiling in deionized water. This further enhances corrosion resistance and durability.

Conventional Anodization (Sulfuric Acid Anodizing):

Sealing: Conventional anodization also includes sealing, but the emphasis is more on achieving color retention and corrosion resistance. The sealing process may involve hot water sealing or the use of various sealants.

5. Appearance:

Aluminum Hard Coating (Hard Anodization):

Appearance: Hard anodization usually results in a matte or natural finish, although it can be dyed to achieve various colors. The primary focus is on enhancing mechanical properties rather than aesthetics.

Conventional Anodization (Sulfuric Acid Anodizing):

Appearance: Conventional anodization offers more flexibility in achieving decorative finishes and colors. It can create bright, satin, matte, or textured finishes, making it suitable for applications where aesthetics are important.

6. Applications:

Aluminum Hard Coating (Hard Anodization):

Applications: Hard anodization is primarily used in applications where hardness, wear resistance, and durability are critical. It finds use in industries like aerospace, automotive, and industrial machinery for components such as pistons, cylinders, and gears.

Conventional Anodization (Sulfuric Acid Anodizing):

Applications: Conventional anodization is more versatile in terms of appearance and is commonly used in architectural, consumer electronics, and automotive industries. It is suitable for parts where corrosion resistance and aesthetic finishes are desired, such as aluminum window frames, electronic housings, and decorative components.

In summary, the key distinction between aluminum hard coating (hard anodization) and conventional anodization lies in their primary purpose and the resulting properties of the treated aluminum. Hard coating anodization is specifically tailored to enhance hardness and wear resistance, making it ideal for applications requiring mechanical durability. Conventional anodization, on the other hand, focuses more on corrosion protection and aesthetics, with a thinner oxide layer. The choice between these processes depends on the specific requirements of the application and the desired properties of the aluminum surface.

Types of Aluminum Anodization:

Type I – Chromic Acid Anodizing:

Type I anodization uses chromic acid as the electrolyte. It creates a very thin and soft oxide layer primarily used for surface preparation before adhesive bonding or painting. It doesn’t significantly improve hardness or corrosion resistance.

Type II – Sulfuric Acid Anodizing:

Type II anodization employs sulfuric acid as the electrolyte. It is the most common form of anodization used for decorative finishes, corrosion protection, and dyeing to achieve various colors. The resulting oxide layer is relatively thin and porous.

Type III – Hard Anodizing:

Type III anodization, also known as hard anodization, is specifically designed to produce a thick and hard oxide layer. It offers superior hardness, wear resistance, and corrosion resistance. This type is ideal for applications where durability is paramount, such as in the aerospace and automotive industries.

In summary, the key difference between hard coating anodization and conventional anodization lies in their purpose, properties, and the resulting thickness of the oxide layer. Hard anodization is optimized for hardness and wear resistance, while conventional anodization focuses on corrosion protection and aesthetics. The type of anodization used depends on the desired outcome and the specific requirements of the application.

The Importance of Sealing Hard Coat Anodizing

The sealing of hard coating anodization (hard anodization) is of paramount importance in ensuring the effectiveness and longevity of the treated aluminum component. Here’s why sealing is crucial:

Enhanced Corrosion Resistance: Hard anodization creates a dense, thick oxide layer on the aluminum’s surface, which already offers excellent corrosion resistance. However, this layer may still have microscopic pores and openings. Sealing the anodized layer closes these pores, making it impervious to moisture, chemicals, and other corrosive agents. This additional barrier greatly enhances the component’s overall corrosion resistance, making it suitable for outdoor and harsh environments.

Improved Durability: The sealing process not only provides corrosion protection but also enhances the overall durability of the anodized surface. It makes the surface less susceptible to wear, abrasion, and damage, further extending the lifespan of the treated aluminum component.

Maintains Aesthetic Finishes: In applications where appearance matters, such as architectural elements or consumer products, sealing helps retain the desired color and finish achieved through anodization. Without sealing, the anodized layer’s appearance may deteriorate over time due to exposure to environmental factors.

Reduced Porosity: Sealing reduces the porosity of the anodized layer. This reduction in porosity minimizes the chances of any residual chemicals or contaminants being trapped within the pores during the anodization process, ensuring a cleaner and more reliable surface.

Enhanced Insulation Properties: In some applications, particularly in the electronics industry, anodized aluminum is used for its electrical insulation properties. Sealing further improves these properties, making it safer and more reliable for electrical components and enclosures.

Improved Chemical Resistance: Sealing can enhance the resistance of the anodized surface to various chemicals, making it suitable for applications where exposure to aggressive substances is a concern.

In summary, sealing hard coating anodization is vital because it significantly enhances the corrosion resistance, durability, and overall performance of the treated aluminum component. It ensures that the benefits of hard anodization, such as increased hardness and wear resistance, are complemented by robust protection against environmental and chemical factors.

Hard Coat Anodizing Features and Limitations

Hard coating anodization, also known as hard anodization, offers several distinct characteristics and advantages, but it also has some limitations. Here are the key features and limitations of hard anodization:

Characteristics and Advantages:

Enhanced Hardness: Hard anodization significantly increases the surface hardness of aluminum, typically achieving hardness values ranging from 40 to 70 on the Rockwell C scale (HRC). This makes it highly resistant to wear and abrasion.

Improved Wear Resistance: The dense and thick oxide layer formed during hard anodization provides exceptional wear resistance, making it suitable for components subjected to mechanical stress.

Corrosion Resistance: While the primary focus is on hardness, hard anodization also improves the corrosion resistance of aluminum. The sealed anodized layer acts as a barrier against environmental factors.

Electrical Insulation: Hard anodized aluminum exhibits excellent electrical insulation properties, making it suitable for electrical and electronic applications.

Dimensional Stability: The hard anodized layer is stable and does not undergo significant dimensional changes, ensuring consistent performance over time.

Customizable Colors: Although the primary goal is not aesthetics, hard anodization can be dyed to achieve various colors, allowing for some degree of customization.

Limitations:

Thickness Limitation: Achieving the desired hardness requires a relatively thick anodized layer, typically ranging from 25 to 100 microns or more. This thickness may not be suitable for all applications, particularly those with tight tolerances.

Cost: Hard anodization processes can be more complex and time-consuming than standard anodization, leading to higher processing costs.

Limited Aesthetics: Hard anodization primarily focuses on mechanical properties and wear resistance, so it may not be the best choice for applications where aesthetics and decorative finishes are crucial.

Brittleness: While hard anodization enhances hardness, it can make the surface more brittle. This may not be suitable for components subjected to extreme flexing or impact.

Surface Finish: The resulting surface of hard anodized aluminum is typically matte or natural. Achieving mirror-like or highly polished finishes can be challenging.

Material Selection: Not all aluminum alloys are suitable for hard anodization, and the choice of alloy can impact the process’s effectiveness.

In summary, hard coating anodization offers exceptional hardness and wear resistance, making it ideal for specific industrial applications. However, its limitations, such as thickness requirements and limited aesthetics, mean that it may not be the best choice for every situation. Careful consideration of the requirements and characteristics of the component is necessary when deciding whether to use hard anodization.

Hard Coat Anodizing Standard Specification

Hard coating anodization, also known as hard anodization, is subject to various standard specifications and guidelines to ensure quality and consistency in the process. Some of the commonly referenced standards for hard anodization include:

MIL-A-8625F – This is a U.S. military specification that covers the anodic coatings on aluminum and aluminum alloys. Section 3.4.1 specifically addresses hard anodizing, outlining requirements for hardness, thickness, and other properties.

ISO 10074:2010 – This international standard provides guidelines for the selection of pretreatments to be used before the application of paints and related products. It includes recommendations for hard anodizing as a pretreatment.

ASTM B580 – This standard provides a guide for performing microhardness tests on electrodeposited coatings. It can be referenced for evaluating the hardness of hard anodized layers.

AMS 2469 – This specification is specific to hard anodizing of aluminum and aluminum alloys. It covers requirements for hardness, thickness, and appearance.

BS EN 2536:2012 – This European standard outlines the requirements for hard anodizing of aluminum and aluminum alloys. It covers specifications for thickness, hardness, and other relevant properties.

AS 1231:2000 – This Australian standard provides guidelines for anodic oxidation coatings on aluminum and aluminum alloys. It includes requirements for hard anodizing.

JIS H 8625 – This Japanese Industrial Standard specifies the hard anodizing process for aluminum and aluminum alloys. It includes requirements for thickness, hardness, and testing methods.

It’s important to note that the specific standards and specifications applicable to hard anodization may vary depending on the region, industry, and application. When performing hard anodization or seeking compliance with specific standards, it is crucial to consult the relevant standard documents to ensure that all requirements are met. These standards typically address parameters such as layer thickness, hardness, corrosion resistance, and appearance to ensure the quality and reliability of hard anodized coatings.

Hard Coating Anodizing Problems and Solutions

Hard coating anodization, like any industrial process, can encounter common issues or challenges. Here are some of the typical problems that may arise during hard anodization and possible solutions:

Inadequate Hardness:

Problem: The resulting hardness of the anodized layer does not meet the desired specifications.

Solution: Check and optimize the anodization process parameters, including voltage, current density, and temperature, to ensure proper oxide layer formation. Ensure the aluminum alloy used is suitable for hard anodization.

Uneven Coating:

Problem: Variations in the anodized layer’s thickness or appearance on the same part.

Solution: Address issues with electrical contact, racking, or agitation within the anodization bath to ensure uniformity. Adjust process parameters to maintain consistency.

Pitting or Defects:

Problem: Small pits or defects on the anodized surface.

Solution: Improve pre-anodization cleaning and etching processes to remove contaminants and imperfections. Ensure proper rinsing between process stages to prevent contamination.

Color Inconsistency:

Problem: Inconsistent or uneven coloring when dyeing the anodized layer.

Solution: Follow precise dyeing procedures, including temperature and dye concentration control, to achieve uniform coloration. Properly rinse parts before and after dyeing to avoid contamination.

Sealing Issues:

Problem: Inadequate sealing, leading to reduced corrosion resistance.

Solution: Verify that the sealing process is carried out correctly, including using the appropriate sealing solution and temperature. Extend the sealing time if needed to ensure complete closure of pores.

Peeling or Flaking:

Problem: The anodized layer may peel or flake off after some use.

Solution: Check for inadequate cleaning or preparation before anodization. Ensure that the aluminum surface is free from oils, greases, or contaminants. Properly bond the anodized layer with the substrate during the sealing process.

Rough or Textured Finish:

Problem: The anodized surface may exhibit an unintended rough or textured finish.

Solution: Adjust the etching process, and consider using a more controlled and precise etching method. Properly agitate and maintain the anodization bath for consistent results.

Excessive Energy Consumption:

Problem: High energy consumption during the anodization process.

Solution: Optimize process parameters to reduce energy usage while maintaining the desired results. Ensure that rectifiers and equipment are functioning efficiently.

Material Compatibility:

Problem: Some aluminum alloys may not be suitable for hard anodization.

Solution: Verify that the chosen aluminum alloy is compatible with the hard anodization process. Consult material specifications or experts for guidance.

Quality Control:

Problem: Inadequate quality control measures can lead to variations in the anodized layer’s properties.

Solution: Implement rigorous quality control procedures, including thickness and hardness testing, to monitor and ensure the consistency and quality of the anodized coatings.

Addressing these common issues through careful process control, material selection, and quality assurance measures can help ensure successful hard anodization and the desired properties of the treated aluminum components.

Hard Coating Anodizing Application

Hard coating anodization, often referred to as hard anodization, finds a wide range of applications across various industries due to its exceptional hardness, wear resistance, and durability. Here are some key applications where hard anodization is commonly used:

Aerospace Industry:

Hard anodization is widely employed in the aerospace sector for components such as pistons, cylinders, landing gear parts, and aircraft engine components. The increased hardness and wear resistance enhance the performance and longevity of these critical parts.

Automotive Industry:

Automotive applications for hard anodization include the treatment of components like pistons, cylinders, and suspension parts. The hardness and wear resistance of hard anodized surfaces improve the durability of these parts, contributing to longer service life.

Industrial Machinery:

Hard anodization is used in the manufacturing of machinery components subjected to high levels of friction and wear. Examples include gears, couplings, and bearings. The increased wear resistance helps extend the life of these components.

Firearms and Defense:

Firearms manufacturers often apply hard anodization to gun components like receivers, barrels, and slides. The added hardness and corrosion resistance contribute to improved firearm performance and longevity. It is also used in various defense applications for wear-resistant parts.

Medical Devices:

Certain medical devices and surgical instruments benefit from hard anodization to increase their wear resistance and corrosion resistance. This is particularly important for devices that require frequent sterilization and extended use.

Electronics and Semiconductors:

Hard anodized aluminum is used in electronic components and semiconductor manufacturing due to its excellent electrical insulation properties. It provides a protective, non-conductive layer for sensitive electronic parts and equipment.

Sporting Goods:

Hard anodization is employed in the production of sporting goods, such as bicycle components, fishing reels, and climbing gear. The increased wear resistance and durability enhance the performance and longevity of these products.

Architectural and Construction:

In architectural applications, hard anodized aluminum is used for elements like window frames, door hardware, and facade cladding. The corrosion resistance and durability make it suitable for outdoor and high-traffic environments.

Marine Industry:

Components exposed to the harsh marine environment, such as boat fittings, fasteners, and deck hardware, are often hard anodized to protect against corrosion and wear.

General Engineering:

Hard anodization is utilized in various engineering applications where increased hardness, wear resistance, and corrosion resistance are required, including in the manufacturing of tooling and mechanical components.

These are just a few examples of the diverse range of applications where hard anodization plays a crucial role in improving the performance, durability, and reliability of aluminum components. Its ability to enhance surface properties makes it valuable in industries where wear and corrosion resistance are essential.

Conclusion

Hard coat anodizing, commonly known as hard anodizing, is a surface treatment process for aluminum that provides exceptional hardness, wear resistance and durability. This versatile technology is used in a wide variety of industries including aerospace, automotive, industrial machinery, firearms, medical devices, electronics, sporting goods, construction, marine and general engineering.

Hard anodizing does have limitations, including the need for relatively thick anodized layers, increased processing costs, limited aesthetic options, brittleness, and specific material requirements.

Hard anodizing is a valuable process that enhances the performance, life and reliability of aluminum CNC machined parts in a variety of critical applications. Its unique combination of properties makes it indispensable in industries where resistance to wear and corrosion is critical to success.

CNCMF offers professional hard coat anodizing and aluminum anodizing services to bring you the best value. With our high-quality workmanship and cutting-edge equipment, we ensure high-quality, precise and affordable coated parts. Contact us for immediate one-on-one support and a quote.

Hard Coat Anodizing FAQs

Certainly, here are answers to common questions about hard coating anodization:

1. How does hard coating anodization affect the dimensions of parts?

Answer: Hard coating anodization typically adds a relatively thin layer to the surface of parts, resulting in minimal changes to their dimensions. The impact on dimensions is generally negligible.

2. Can aluminum hard coating be dyed or colored?

Answer: Yes, aluminum hard coating can be dyed or colored to achieve various shades. This allows for customization of the appearance while retaining the benefits of increased hardness and wear resistance.

3. What types of seals can be used for aluminum hard coating?

Answer: Common sealing methods for aluminum hard coating include hot water sealing and various proprietary sealing solutions. The choice of sealant depends on specific requirements for corrosion resistance and appearance.

4. How can maximum adhesion be achieved on aluminum hard coating?

Answer: To maximize adhesion on aluminum hard coating, proper surface preparation is crucial. Ensure thorough cleaning and etching of the aluminum surface before anodization. Following industry-standard practices for surface preparation is essential.

5. How can aluminum hard coating be easily removed?

Answer: Aluminum hard coating is challenging to remove due to its hardness and durability. It typically requires abrasive methods such as sandblasting or chemical stripping using strong alkaline solutions.

6. What is the maximum coating thickness for high-pressure aluminum hard coating?

Answer: The maximum coating thickness for high-pressure aluminum hard coating can vary but often ranges from 25 to 100 microns (µm) or more. The thickness depends on the specific requirements of the application.

7. How long does hard coating anodization last?

Answer: The durability of hard coating anodization depends on factors such as the application, environmental conditions, and maintenance. In many applications, it can last for many years, providing long-term protection and wear resistance.

8. How long does it take to perform hard coating anodization?

Answer: The time required for hard coating anodization depends on factors like part size, desired thickness, and process parameters. It can range from several hours to a few days for larger or complex parts.

9. Is aluminum hard coating prone to corrosion?

Answer: Aluminum hard coating significantly improves corrosion resistance compared to untreated aluminum. However, it may not provide absolute protection in highly corrosive environments, and the specific alloy and sealing method used can affect its corrosion resistance.

10. Is hard coating anodization a permanent process?

Answer: Hard coating anodization is a permanent alteration of the aluminum surface, resulting in increased hardness and wear resistance. However, its appearance and properties can be affected by extreme conditions or prolonged exposure to harsh environments.

11. Is aluminum hard coating anodization conductive?

Answer: Aluminum hard coating anodization is not inherently conductive. The anodized layer is typically non-conductive. However, subsequent processes, such as sealing or surface treatments, can be applied to achieve desired electrical conductivity if necessary.

These answers provide insights into common questions about hard coating anodization and its effects on aluminum CNC parts.