Many people will say that our machining cost is 60 RMB ( 9.8 USD) an hour, and some people say that we only quote 35 RMB (5.75 USD) an hour, but we find that the customer still says that our quotation is too high,but I think it is a loss. Why? One minute help you sort out how much the CNC machining factory costs for one hour of processing without losing money?

Here are the factors that affect the cost:

1. The structure of the product, whether we have reasonably planned the production processing of the parts when reviewing the drawings. If the plan is unreasonable, one operator will operate 3 machines, and we use multi-station processing, that is, one mold to process multiple parts , The processing time is long, one person can open more than 6 machines.

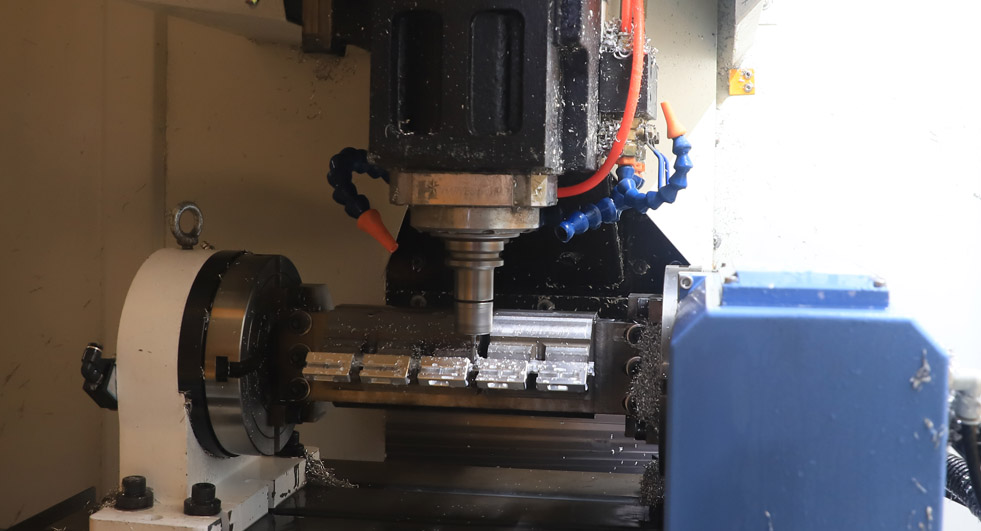

2. The selection of the machine is very important. It is also very important whether you use a 3-axis machine for production or 5-axis production to save time, and we usually use a 3+2-axis machine, which is often referred to as a 4-axis machine. The advantage of processing is that many parts can be processed and arranged on the bridge board at one time, which saves a lot of clamping time and makes full use of the machine’s operating rate.

3. Reasonable selection of the reference level for parts processing, the wrong selection of the second sequence and the third sequence processing is unstable, the machine is transferred back and forth, and the quality of the site and the technicians are busy, but the production capacity is found to be unsatisfied.

4. The fixed cost is too high, and there is no way to reflect the advantage of the weaving cost. What is the weaving cost, that is to say, when we plan a new factory, we have to design it, how many people we have, and how many machines are needed. In order to make full use of the personnel, it is not just as much equipment as the operator wants to buy. In the end, it is found that because there is less one person for the equipment, there are more than two people. When renting a workshop, the unit cost is the machine, personnel, and technology. Ultimately, this will reduce the cost of weaving.

5. Technical ability, all technologies are not constrained by the cost standard, they are self-righteous, the most common fault for technicians, and the most fundamental reason for the impact of cost. For example, the quality of the same parts is stable and efficient. , This is the real technology, but many CNC machining factories do not understand this, or understand but lack of data to show it, so that technicians know their own situation, but lack the ability to optimize and innovate, this is The most critical impact cost.

If you want to know more about the cost of CNC machining factory, please pay attention to our explanation! Thank you.