Achieving complex curved surfaces and multi-axis machining in aluminum CNC machining involves advanced techniques and specialized equipment. Here’s how to do it:

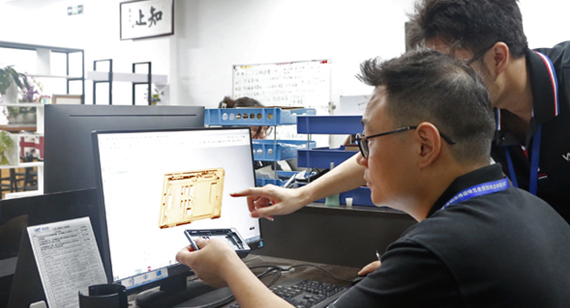

1. CAD/CAM Software:

Start with a detailed 3D CAD (Computer-Aided Design) model of the part. Use CAD software to create a precise representation of the complex surface. Then, use CAM (Computer-Aided Manufacturing) software to generate toolpaths for the CNC machine.

2. Multi-Axis CNC Machine:

Utilize a CNC machine with multi-axis capabilities. While traditional 3-axis machines are suitable for simpler parts, complex curved surfaces often require 4-axis, 5-axis, or even 6-axis machines. These machines can move the tool in multiple directions simultaneously, allowing for intricate contours.

3. Tool Selection:

Choose specialized cutting tools designed for multi-axis machining. These tools are often shorter and more rigid to minimize vibrations and ensure precise cutting.

4. Fixturing and Workholding:

Develop custom fixtures that securely hold the aluminum workpiece while allowing access to multiple angles. The workholding setup should be robust and adaptable to different orientations.

5. Toolpath Generation:

Use CAM software to generate toolpaths that follow the complex surface. 5-axis toolpaths, for example, can tilt and rotate the tool to approach the workpiece from various angles. This flexibility is crucial for achieving complex contours.

6. Simulation and Verification:

Before actual machining, simulate the toolpath to identify any collisions or issues. Verify that the tool can access all required areas of the part without interference.

7. Cutting Parameters:

Optimize cutting parameters such as spindle speed, feed rate, and tool engagement based on the specific requirements of the part and material. These parameters may vary for different areas of the complex surface.

8. Coolant and Lubrication:

Ensure effective coolant and lubrication systems to dissipate heat, reduce friction, and improve chip evacuation. This is essential for maintaining tool life and surface quality.

9. Quality Control:

Implement in-process quality checks and inspections to monitor the part’s accuracy and surface finish during machining. Make necessary adjustments as needed.

10. Programming Expertise:

Skilled CNC programmers with experience in multi-axis machining are essential. They can optimize toolpaths, manage tool changes, and fine-tune machining parameters to achieve the desired results.

11. Post-Processing:

After machining, consider post-processing steps like deburring, surface finishing, or heat treatment if required to meet the final part specifications.

12. Continuous Lmprovement:

Maintain a continuous improvement mindset, collecting data and feedback to refine the process for efficiency and quality.

Achieving complex curved surfaces and multi-axis machining in aluminum CNC machining demands a combination of advanced equipment, software, tooling, and expertise. It’s essential to collaborate closely with CNC programmers and machinists to ensure the successful production of parts with intricate contours and high precision.