To control CNC machining part quality within a tolerance of 0.01mm (10 microns) and maintain consistency, you need to implement a precise and well-structured approach in your manufacturing process. Here are steps and strategies to achieve this:

Design for Manufacturability (DFM): Start with a well-optimized design that considers the manufacturability of the part. Simplify complex features and minimize tight tolerances where possible.

Material Selection: Choose high-quality materials with consistent properties. Material variations can affect part dimensions. Ensure material certifications and traceability.

Advanced CNC Machines: Invest in high-precision CNC machining equipment with tight repeatability and accuracy. Modern machines often have built-in features for improved precision.

Tooling and Cutting Tools: Use high-quality cutting tools made from appropriate materials. Regularly inspect and replace tools to maintain sharpness. Proper tool selection is critical.

Fixturing and Workholding: Ensure secure and stable workholding methods to prevent part movement during machining. Precision fixtures and clamping systems are essential.

Calibration and Maintenance: Regularly calibrate and maintain your CNC machines and measurement equipment. This ensures accuracy over time.

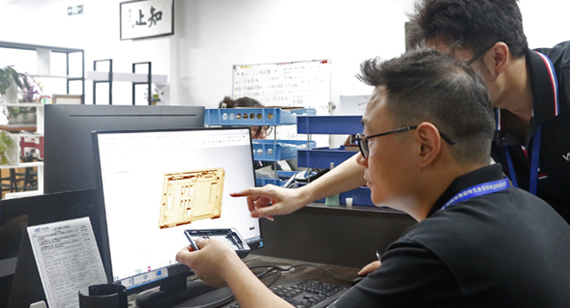

Toolpath Optimization: Use CAM (Computer-Aided Manufacturing) software to generate toolpaths that optimize tool engagement and minimize tool deflection.

Coolant and Lubrication: Use the appropriate coolants and lubricants to reduce friction and heat during machining. This can help maintain tight tolerances.

In-Process Inspection: Implement in-process inspection using precision measuring instruments such as micrometers, calipers, and coordinate measuring machines (CMMs) to monitor part dimensions as they are being machined.

Statistical Process Control (SPC): Use SPC techniques to monitor and control the machining process. Collect data on critical dimensions and analyze it to identify trends and variations.

Quality Control Plan: Develop a comprehensive quality control plan that includes inspection points, measurement methods, and acceptable tolerances. Train operators and inspectors on the plan.

Documentation and Traceability: Maintain detailed records of part specifications, manufacturing processes, and inspection results. Traceability helps identify issues and maintain consistency.

Feedback Loop: Establish a feedback loop where any deviations from the specified tolerances trigger corrective actions. Investigate the root causes of variations and make necessary adjustments.

Operator Training: Provide thorough training to machine operators and inspectors on the importance of precision and the specific quality standards for the parts they are working on.

Continuous Improvement: Continuously review your processes and quality control measures. Seek opportunities for improvement and apply lessons learned to enhance consistency.

By following these steps and adopting a holistic approach to precision machining, you can maintain tight tolerances of 0.01mm and ensure consistent part quality. Consistency is achieved through a combination of design considerations, equipment, processes, and quality control measures.