Collaborating with CNC machining service manufacturers effectively is crucial to achieving the best results for your projects. Here are some key strategies to ensure a successful partnership:

Clear Communication:

Establish open and clear communication channels with the CNC machining service provider. Clearly communicate your project requirements, specifications, and expectations.

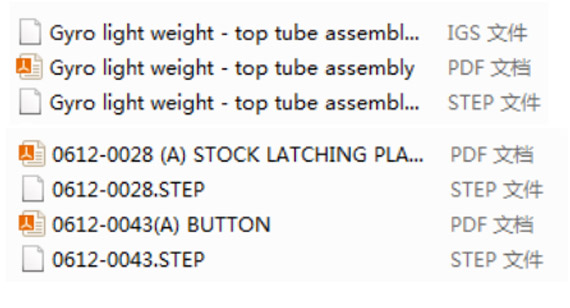

Detailed Project Documentation:

Provide comprehensive project documentation, including detailed engineering drawings, 3D models, and any specific requirements. Clarity in documentation helps avoid misunderstandings and ensures accurate production.

Define Quality Standards:

Clearly define your quality standards and expectations for the finished products. Discuss tolerances, surface finishes, and any other critical parameters to ensure alignment between your expectations and the capabilities of the CNC machining service.

Material Specifications:

Clearly specify the materials you require for your project. Discuss material properties, grades, and any special considerations related to the application of the finished parts.

CNC Prototype and Sample Approval:

Request CNC prototype or sample parts before full-scale production. This allows you to assess the quality and functionality of the machined parts and provides an opportunity for adjustments if needed.

Visit the Facility:

If possible, visit the CNC machining facility to assess their capabilities firsthand. This helps build a better understanding of their processes, equipment, and overall production environment.

Discuss Lead Times:

Clearly communicate your project timelines and deadlines. Discuss lead times for both prototyping and full-scale production to ensure that the CNC machining service provider can meet your schedule.

Quality Assurance and Inspection Procedures:

Inquire about the CNC machining service provider’s quality assurance and inspection procedures. Understand how they ensure the quality of finished parts, including the use of inspection equipment and adherence to industry standards.

Flexibility and Customization:

Discuss the flexibility of the CNC machining service provider to accommodate custom requirements or design changes during the production process. A flexible partner can better adapt to your evolving needs.

CNC Machining Cost Transparency:

Seek transparency in cost structures. Understand how the CNC machining service provider calculates costs, including material costs, CNC machining costs, and any additional fees. This ensures there are no surprises in the final invoice.

Continuous Communication:

Maintain ongoing communication throughout the project. Regular updates and feedback exchanges help address any issues promptly and ensure that the project stays on track.

Intellectual Property Protection:

Discuss and establish agreements regarding intellectual property protection. Ensure that your designs and project details are treated with confidentiality and that the CNC machining service provider respects your proprietary information.

Post-Production Support:

Inquire about post-production support, including warranty, maintenance, or any other services offered after the completion of the project.

By implementing these strategies and fostering a collaborative and transparent relationship, you can maximize the effectiveness of your collaboration with CNC machining service manufacturers, leading to successful and high-quality outcomes for your projects.