Understanding the Culprits: Burrs and Scratches

Burrs and scratches are common issues that can arise during the CNC machining process, and addressing them effectively is crucial to delivering high-quality aluminum CNC components.

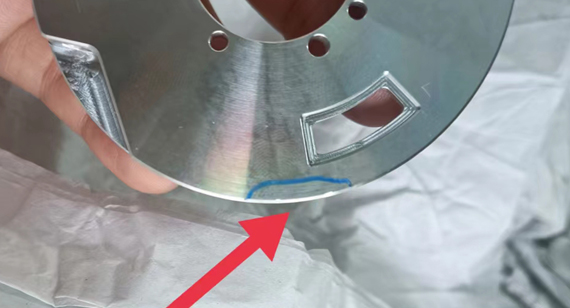

Burrs are raised edges or rough areas on the machined surface. They can be quite small but are still visible and can compromise the aesthetics and functionality of the part. Burrs are typically the result of cutting tools that are not properly maintained or when the cutting parameters are not optimized.

Scratches, on the other hand, are linear marks on the surface of the part. These can be caused by a variety of factors, including debris on the tool or material, improper toolpath strategies, or inadequate lubrication. Scratches are not just unsightly; they can also weaken the structural integrity of the part.

Addressing Burrs and Scratches

Even with preventive measures, burrs and scratches can sometimes occur. In such cases, it’s essential to know how to address these issues without compromising the part’s integrity.

1. Deburring: Use deburring tools or techniques to remove burrs. These tools are designed to safely shave off raised edges without causing additional damage. Deburring should be done with precision to avoid overcutting.

2. Polishing: For scratches or light surface imperfections, polishing may be effective. Various abrasives and compounds are available for aluminum parts that can help restore a smooth finish.

3. Re-Machining: In some instances, re-machining the affected area may be necessary. This can be done using a finer tool and adjusted parameters to eliminate surface defects.

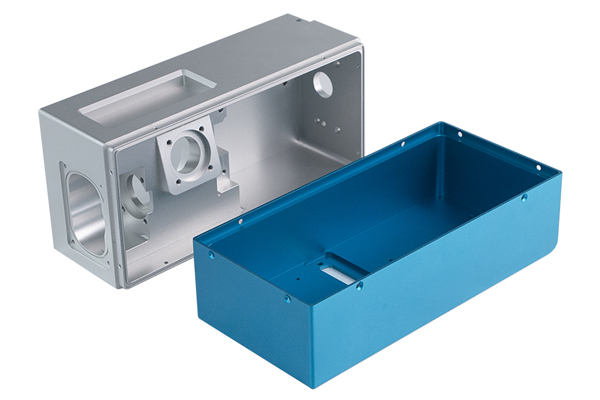

4. Anodizing or Coating: Anodizing or applying protective coatings not only enhances the appearance of aluminum parts but can also help hide minor imperfections.

Preventing Burrs and Scratches

Burr and scratch issues in CNC machined aluminum parts can be both a nuisance and a hindrance to product quality. Fortunately, there are several steps and strategies you can employ to address and prevent these imperfections, ensuring your aluminum CNC machined parts are of the highest quality.

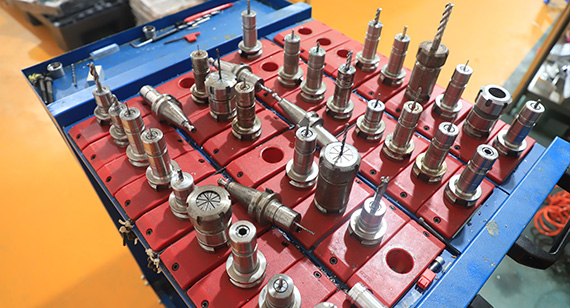

Tool Selection: The choice of cutting tools plays a significant role in minimizing burrs and scratches. Opt for high-quality tools that are sharp and well-maintained. Dull or damaged tools are more likely to cause these issues.

Proper Speeds and Feeds: Ensuring the correct cutting speeds and feeds is crucial. Too high a speed or too slow a feed can lead to burrs and scratches. Consult the tool manufacturer’s recommendations and, if possible, perform test cuts to find the optimal settings.

Clamping and Fixturing: Securely clamping the workpiece is essential. Any movement or vibration during machining can result in unwanted marks. Well-designed fixtures and proper clamping techniques can help prevent this.

Chip Control: Effective chip control can help prevent burrs. Clearing away chips promptly can reduce the likelihood of them being pressed against the workpiece, causing scratches.

Tool Path Optimization: Consider the tool path and the order of operations. A well-planned tool path can minimize the chances of re-cutting chips or dragging them across the workpiece surface.

Coolant and Lubrication: Proper coolant and lubrication can reduce friction and heat generation during machining, which can lead to burrs and scratches. Make sure the coolant is compatible with the material being machined.

Inspection and Quality Control: Implement a rigorous inspection process. Check parts for burrs and scratches immediately after machining. Identifying and addressing these issues early can save time and resources.

Deburring and Polishing: If burrs and scratches are present, invest in post-machining deburring and polishing processes. Various methods, including manual and automated techniques, can be used to remove imperfections.

Material Quality: Sometimes, the material quality itself can contribute to burrs and scratches. Ensure you’re using high-quality aluminum stock that’s free from defects.

Operator Training: Well-trained operators are more likely to produce high-quality parts. Ensure your CNC machine operators are skilled in the art of minimizing burrs and scratches.

Continuous Improvement: Establish a culture of continuous improvement. Analyze any reoccurring issues and take steps to prevent them in the future. This might involve adjusting tooling, altering feeds and speeds, or improving fixturing.

Communication: Effective communication between design, engineering, and machining teams is essential. Discuss any known issues or challenges and work collaboratively to find solutions.

In summary, achieving a high-quality finish in aluminum CNC machined parts requires attention to detail, from tool selection and feeds and speeds to clamping, chip control, and post-machining inspection. By implementing these strategies and maintaining a commitment to excellence, you can ensure your CNC machined aluminum components meet the highest standards of quality.

Conclusion

Handling burrs and scratches in aluminum CNC machined parts is a critical aspect of delivering high-quality components. By implementing preventive measures and knowing how to address these issues when they arise, you can ensure that your CNC machining projects meet the highest standards of quality and aesthetics.

In the competitive world of CNC machining, the ability to consistently produce pristine parts sets you apart from the rest. Whether you’re a professional machinist or a project CNC machining manufacturer seeking reliable manufacturing partners, understanding and implementing these strategies is key to achieving exceptional results.