In the world of CNC machining, precision and consistency are paramount, especially when working with aluminum, a material known for its versatility and wide range of applications. However, dealing with process variations and deviations can be a challenge. This article will provide you with insights and strategies to overcome these hurdles and consistently produce high-quality aluminum CNC parts.

Understanding Process Variations and Deviations

Process variations and deviations can be caused by various factors in the CNC machining process. These factors include tool wear, machine calibration, material inconsistencies, and operator errors. The key to managing these issues is a combination of preventive measures, monitoring, and corrective actions.

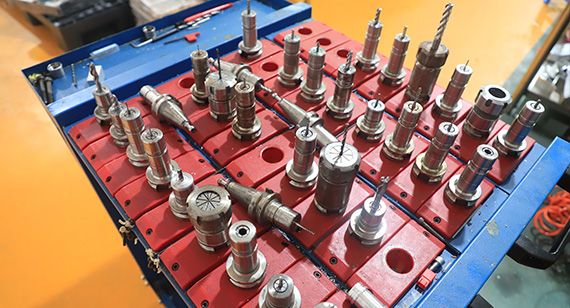

1. Tool Management

One of the primary sources of process variations in CNC machining is tool wear. Over time, cutting tools can become dull, leading to inaccuracies and deviations in the final product. To address this issue:

Regular Tool Inspection: Implement a routine tool inspection schedule to identify signs of wear or damage. This will allow for timely tool replacement or reconditioning.

Tool Life Management: Utilize software and tool life management systems to keep track of tool usage. These systems can provide alerts for tool replacement based on actual usage rather than time-based estimates.

2. Machine Calibration

Machine tools can also contribute to variations in the manufacturing process. Proper machine calibration and maintenance are essential:

Scheduled Maintenance: Maintain a regular maintenance schedule to ensure that machines are always in optimal working condition.

Calibration Checks: Periodically calibrate your CNC machines to account for any deviations. Calibration ensures that the machine’s positioning and movement are accurate.

3. Material Consistency

Aluminum materials, while widely used, can still have variations in properties. Understanding these material differences is crucial for consistent results:

Material Testing: Consider testing and verifying the material properties before production. This can include tensile strength, hardness, and thermal conductivity.

Material Sourcing: Ensure that you source materials from reputable suppliers with consistent quality standards.

4. Operator Training

The skill and knowledge of the machine operators play a significant role in minimizing process variations:

Operator Training: Invest in training and continuous education for your machine operators. Well-trained operators are more likely to detect and address deviations during the machining process.

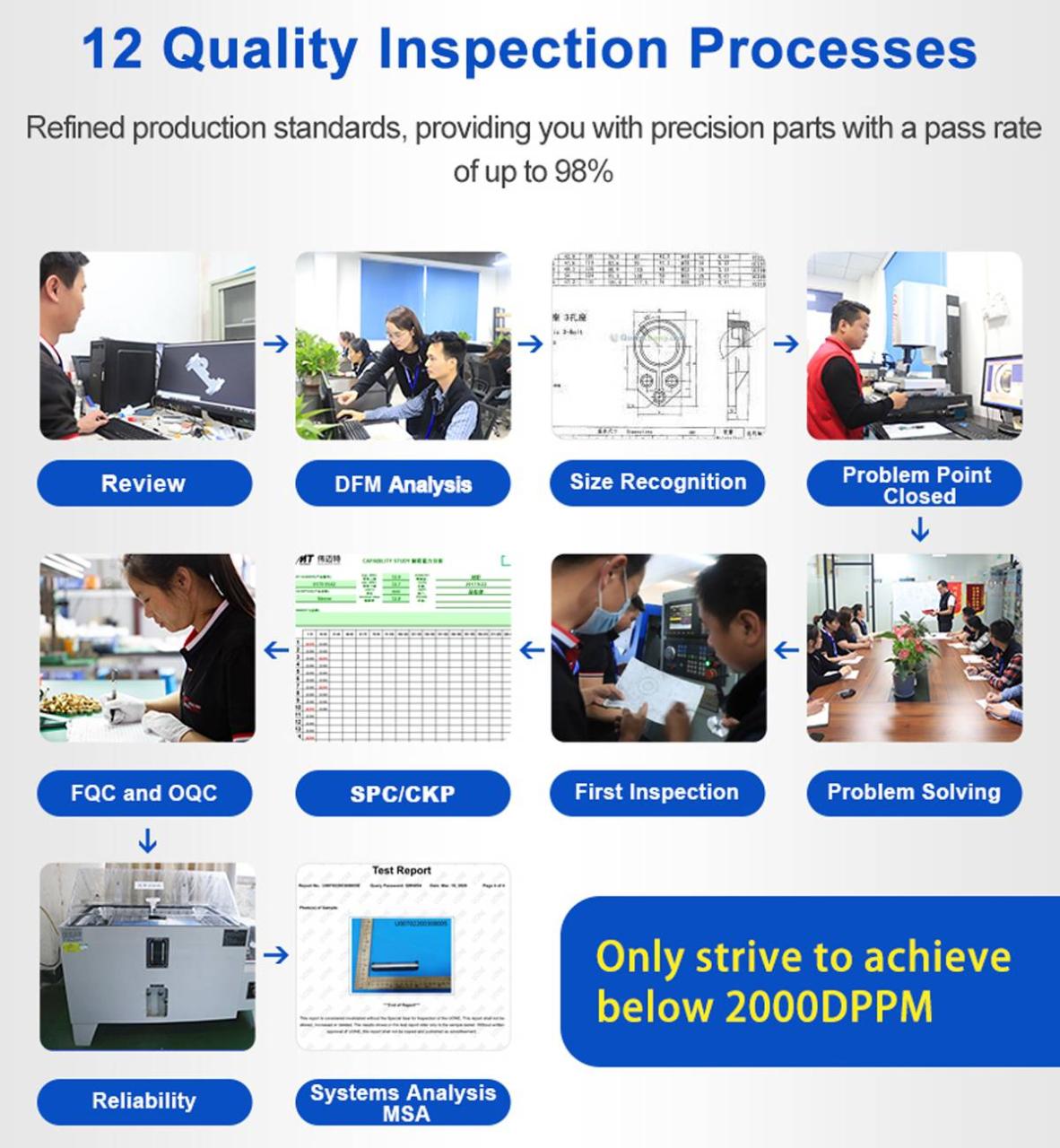

Monitoring and Quality Control

Implementing monitoring and quality control measures is vital to detect and address variations in real-time:

In-Process Inspection: Incorporate in-process inspections to verify the dimensions and quality of parts as they are being machined. This allows for immediate corrective actions.

Quality Control Software: Implement quality control software that can monitor and analyze the machining process, providing real-time data and alerts if any variations or deviations are detected.

Corrective Actions

When process variations or deviations are detected, it’s essential to have clear protocols for corrective actions:

Root Cause Analysis: Determine the underlying causes of variations. Was it a tool issue, machine problem, or material inconsistency?

Adjustments and Corrections: Based on the root cause analysis, make the necessary adjustments, whether it’s changing the tool, recalibrating the machine, or addressing material issues.

By addressing process variations and deviations in aluminum CNC machining, you can consistently deliver high-quality parts that meet your specifications. Implementing a comprehensive quality control system and providing ongoing training to your team will further enhance your ability to manage and optimize the production process.

1. Data-Driven Decision Making

In the world of CNC machining, data is a powerful ally. By collecting and analyzing data throughout the machining process, you can gain valuable insights into the sources of variations and deviations. This data-driven approach can help you make informed decisions to improve the process:

Data Collection: Implement data collection systems to record information such as tool wear, machine performance, and material characteristics.

Data Analysis: Use statistical analysis and data visualization tools to identify trends and patterns that can lead to process improvements.

Continuous Improvement: Regularly review the data and use it to drive continuous improvement initiatives. This might involve adjusting tooling strategies, fine-tuning machine parameters, or optimizing material selection.

2. Communication and Collaboration

Effective communication within your CNC machining team is essential to address process variations and deviations. Encourage collaboration and open dialogue between operators, programmers, and quality control personnel:

Team Meetings: Schedule regular meetings to discuss ongoing projects, challenges, and opportunities for process improvement.

Feedback Loop: Create a feedback loop where operators can report issues and deviations in real-time, allowing for swift corrective actions.

3. Lean Manufacturing Principles

Implementing lean manufacturing principles can significantly reduce process variations and enhance efficiency in CNC machining:

Waste Reduction: Identify and eliminate waste in the manufacturing process, whether it’s through excessive tool changes, inefficient material handling, or unnecessary machine downtime.

Standard Work: Develop and follow standardized work procedures to ensure consistency in operations.

Kaizen Philosophy: Embrace the Kaizen philosophy of continuous improvement, encouraging all team members to suggest and implement small but impactful changes.

Preventive Strategies for Consistency

In addition to monitoring and corrective actions, a proactive approach to preventing process variations and deviations is crucial for maintaining a high level of consistency in aluminum CNC machining. Here are some preventive strategies to consider:

1. Design for Manufacturability (DFM)

Begin the process by optimizing your part designs for CNC machining. DFM principles can help reduce complexities that might introduce variations. Work closely with your design team to ensure that the part’s geometry, tolerances, and features are manufacturable with minimal deviations.

2. Material Selection

Choosing the right aluminum alloy is vital. Different alloys have varying machining characteristics. Understand the properties of the chosen material and select one that aligns with your project’s requirements. A consistent material will lead to more predictable machining outcomes.

3. Standardized Work Instructions

Develop standardized work instructions for your machining processes. These instructions should cover tool selection, feeds, speeds, and other critical parameters. Ensure that all machine operators follow these instructions meticulously.

4. Quality Control Systems

Implement a comprehensive quality control system that includes regular audits and checks at different stages of production. Inspections can help catch any deviations early in the process, preventing further waste and rework.

5. Machine Tool Maintenance

Regular machine maintenance is fundamental to consistent machining. Ensure that all machines are serviced and calibrated on schedule. Proper machine maintenance extends the lifespan of the equipment and improves its accuracy.

6. Statistical Process Control (SPC)

SPC tools can help monitor and analyze machining processes statistically. By collecting and analyzing data, you can identify trends and patterns, allowing you to take proactive measures before variations become significant.

Continuous Improvement

Consistency is an ongoing pursuit. Continuous improvement is the key to long-term success in managing process variations and deviations. Regularly review your processes, gather feedback from your team, and look for opportunities to enhance your CNC machining capabilities.

In conclusion, managing process variations and deviations in aluminum CNC machining is an important aspect of consistently delivering high-quality parts. Ensure you consistently provide your customers with high-quality aluminum CNC parts by focusing on prevention strategies, implementing robust monitoring and quality control measures, and continually seeking improvements.