Introduction:

With the rapid advancement of the manufacturing industry, the demand for custom CNC machining is on the rise. Ensuring the stability and reliability of custom CNC machining capabilities is crucial for enhancing product quality, reducing production costs, and maintaining the reputation of businesses. This article explores how to ensure the stability and reliability of custom CNC machining capabilities, along with the key elements of implementing related strategies.

I. Enhancing Equipment Performance and Maintenance:

Equipment Selection and Configuration:

Choose CNC machining equipment with stable performance and high precision based on machining requirements. Configure equipment parameters reasonably to ensure it meets processing requirements.

Regular Maintenance:

Develop a maintenance plan for CNC machining equipment, regularly inspect, clean, lubricate, and adjust the equipment to ensure it remains in good working condition.

Prevention and Handling of Equipment Failures:

Establish a mechanism for preventing and handling equipment failures. Detect and resolve equipment issues promptly to prevent disruptions to machining capabilities.

II. Optimizing Process Workflow and Parameter Settings:

Process Workflow Development:

Develop scientifically rational process workflows based on part characteristics and machining requirements to ensure a smooth machining process.

Parameter Optimization:

Optimize key parameters such as cutting parameters and tool parameters through experimentation and validation to improve machining efficiency and quality.

Standardized Operations:

Develop standardized operating procedures to regulate employee behavior, reducing the impact of human factors on machining capabilities.

III. Strengthening Quality Inspection and Control:

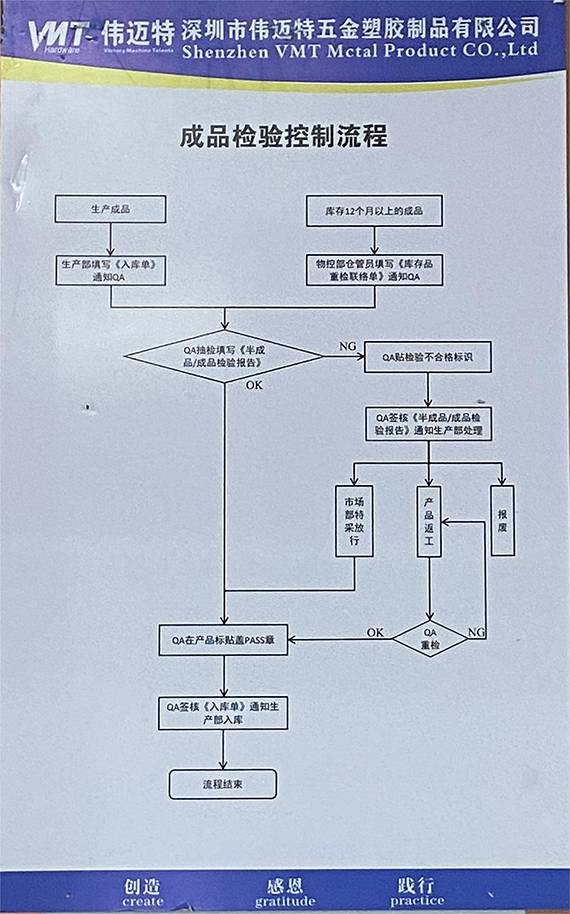

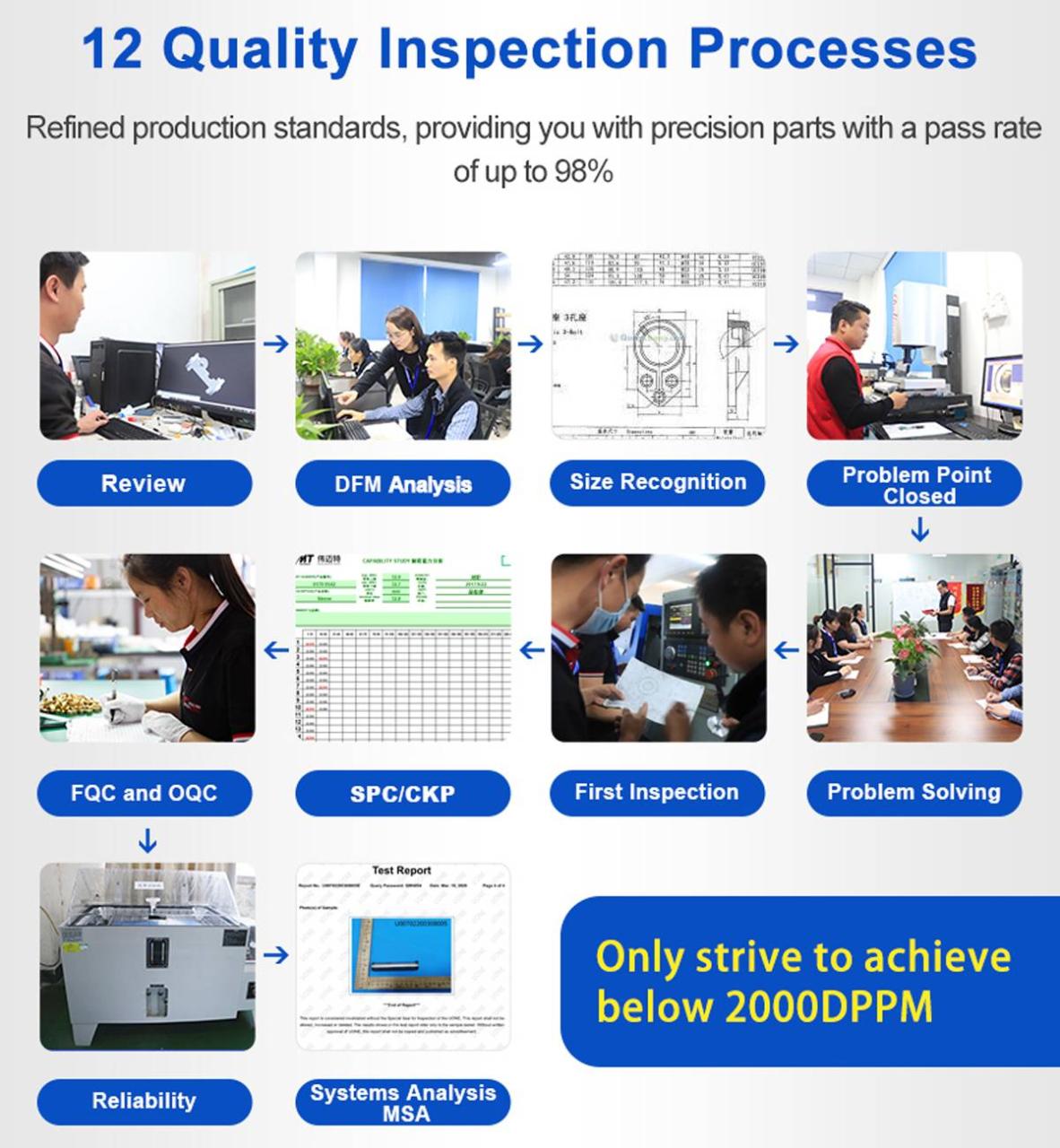

Quality Inspection:

Establish a comprehensive quality inspection system to inspect key points in the machining process, ensuring part quality meets requirements.

Quality Control:

Develop a quality control plan to monitor the machining process, promptly identify and resolve quality issues, preventing the occurrence of batch defects.

Quality Data Analysis:

Regularly collect and analyze quality data to understand the quality status and identify potential issues, providing a basis for further optimizing machining capabilities.

IV. Continuous Training and Talent Development:

Training Plans:

Develop training plans based on employee skill levels and job requirements to enhance employee skills and operational experience.

Skills Competitions:

Organize skills competitions to stimulate employee enthusiasm for learning and improve overall skill levels.

Talent Recruitment and Development:

Actively recruit talent with professional skills and rich experience, strengthen internal talent development, and enhance the overall team’s capabilities.

V. Supply Chain Management and Partner Relationships:

Supplier Selection:

Choose suppliers with good reputations and stable performance to ensure the reliability of raw materials and components.

Supply Chain Monitoring:

Establish a supply chain monitoring system to track and manage supplier delivery quality and timelines, ensuring supply chain stability.

Maintaining Partner Relationships:

Build strong partnerships with suppliers and customers, enhance communication and collaboration, and collectively improve custom CNC machining capabilities.

VI. Innovative Technology and Digital Transformation:

Technology Research and Development:

Increase efforts in technology research and development, stay informed about industry trends, and actively introduce and apply advanced CNC machining technologies.

Digital Transformation:

Utilize digital technologies to achieve the intelligence and informatization of the production process, improving production efficiency and the reliability of machining capabilities.

Innovation Incentive Mechanisms:

Establish incentive mechanisms for innovation, encouraging employees to propose improvement ideas and innovative solutions, continuously optimizing machining capabilities.

Conclusion:

In conclusion, ensuring the stability and reliability of custom CNC machining capabilities requires a multifaceted approach. By implementing comprehensive measures such as enhancing equipment performance and maintenance, optimizing process workflows and parameter settings, strengthening quality inspection and control, providing continuous training and talent development, managing the supply chain, fostering partner relationships, and embracing innovative technologies and digital transformation, the stability and reliability of custom CNC machining capabilities can be effectively enhanced. During the implementation of these strategies, attention to key elements and the adoption of effective measures for improvement and optimization are essential to adapt to evolving market demands and technological advancements.