As precision machined components manufacturers continue to increase their productivity, customers usually require annual reductions in the price of processed components, which poses a challenge to the profitability of component manufacturers. For their own survival and development, parts manufacturers must spare no effort to reduce production costs.

Improvement methods include: increasing employee productivity, extending tool life, improving consumable management, and reducing energy consumption. After a long period of exploration, our engineers have discovered an effective method that can extend tool life, improve precision machined components quality, and reduce manufacturing costs.

Causes of tool wear

1. Thermoelectric wear

Due to the different materials of the precision machined components, chips and tools, thermoelectric potential will be generated in the contact area during chip cutting. This thermoelectric potential has the effect of promoting diffusion and accelerating tool wear.

2. Oxidative wear

Precision machined components at a certain cutting temperature, certain components of the tool material and the surrounding medium will have a chemical interaction, forming a layer of lower hardness compound on the surface of the tool and being taken away by the chips, accelerating the wear of the tool. This type of wear is called chemical wear. This is also one of the main reasons why diamond tools cannot cut ferrous metals in the air.

3. Hard point wear

Tool surface wear is caused by hard spots (such as carbides, nitrides and oxides) in the precision machined components material and debris from built-up edge. This kind of high-speed steel tool wear is more significant, and cemented carbide tools are relatively rare. At various cutting speeds, the tool has hard point wear, but it is the main reason for low-speed cutting tool wear.

4. Bonding wear

Bonding refers to the phenomenon of “cold welding” between the tool and the precision machined components material under sufficient pressure and high temperature, and is the result of the adsorption between atoms on the fresh surface of the friction surface. The junction of the two friction surfaces will be torn due to relative movement and taken away by the other side. If the joint on the tool side breaks, it will cause tool wear. Cutting temperature is the main factor affecting bond wear. The higher the cutting temperature, the more severe the bond wear.

5. Diffusion wear

Diffusion wear often occurs at the same time as bond wear. The diffusion wear rate is mainly related to the cutting temperature and the chemical composition of the tool.

Ways to extend tool life

Precision machined components tool wear is related to factors such as geometric angle, cutting force, cutting heat, and cutting consumption. The durability and service life of tools can be extended by subjective efforts.

1. Improve tool geometry angle

Tool angle and blade shape affect the change of precision machined components cutting force. With the increase of the rake angle, the chip deformation is small, the cutting is light, and the cutting force and cutting heat are reduced. On the premise of ensuring that the knife has sufficient strength, the rake angle should be as large as possible. When the entering angle decreases, the length of the cutting edge involved in cutting increases, so that the cutting heat is relatively dispersed, and the increase of the nose angle can reduce the precision machined components cutting temperature.

2. Reasonable selection of precision machined components tool materials

The precision machined components material and processing conditions have a great influence on the cutting performance of the tool. To process different materials, you must know how to choose different tools to meet the cutting requirements.

3. Strengthen daily maintenance

The precision machined components production site, especially the tool holding device, work surface, tool storage, etc. should be thoroughly cleaned. Maintain tool accuracy regularly. Make sure that the screws of the tool and clamping device are tightened. When installing and disassembling, clean up the leaked dirt in time.

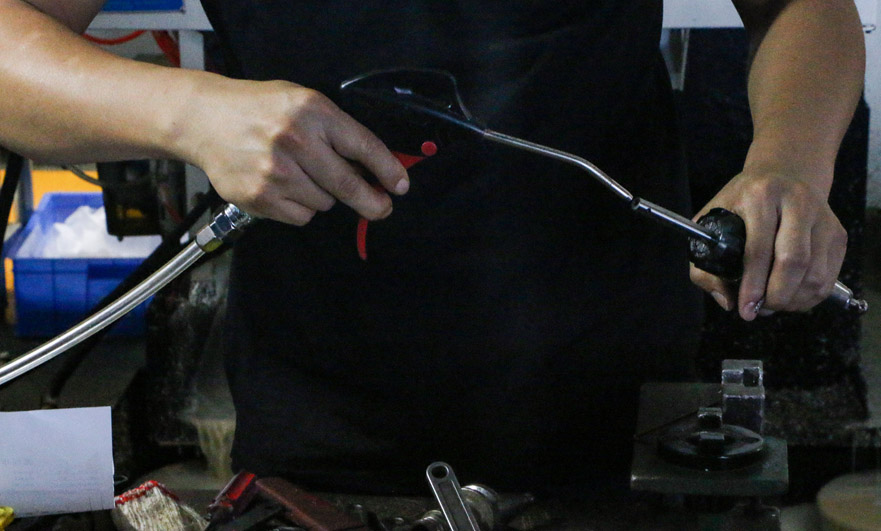

4. Use cooling lubricant

Cooling lubricating fluid can absorb and take away most of the heat in the cutting zone, improve heat dissipation conditions, reduce the cutting temperature of the tool and the precision machined components, reduce tool wear, thereby prolonging the service life of the tool, and preventing the precision machined components from dimensional error due to thermal deformation.

5. Master and adjust the best cutting conditions

Set and maintain good cutting conditions. Understand the cutting status of the accessories through vibration analysis, etc., and adjust them in time, so that the knife has a good working environment. Once the tool is changed, the size must be adjusted to ensure proper fastener conditions and cutting conditions.

6. Reasonably choose the cutting amount

The amount of cutting affects the durability of the tool. If the cutting depth and feed rate are too large, the cutting force will increase, the tool will wear quickly, and the cutting speed will be too high, and the tool and precision machined components will wear out. Therefore, choosing a reasonable cutting amount can also extend the tool life.

TO sum up

In the daily maintenance of tools, the dirt should be cleaned up in time. The different precision machined components materials selected at the beginning of the work must be replaced with corresponding tools, and cooling lubricants must be added to prevent the tools from overheating and chipping. Share it here today, I hope it will be helpful to everyone.

Welcome to visit CNCMF official website for more information. CNCMF will provide you with precision machined components solutions at any time, please feel free to contact us and look forward to your CNC machining projects.