Improving the yield and addressing sand hole issues in the polishing and PVD mirror surface treatment of die-cast CNC machined parts involves a combination of process optimization, quality control measures, and proactive problem-solving. Here are some strategies to enhance the yield and resolve sand hole issues:

1. Optimize Die-Casting Parameters:

Fine-tune die-casting parameters, including temperature, pressure, and cooling rates, to minimize defects in the initial casting process.

2. Quality Die-Casting Materials:

Source high-quality die-casting materials with minimal impurities. The quality of the base material significantly influences the final surface finish.

3. Advanced Mold Design:

Invest in advanced mold designs with efficient gating and venting systems. Proper mold design helps reduce defects like porosity, which can affect the polishing and coating processes.

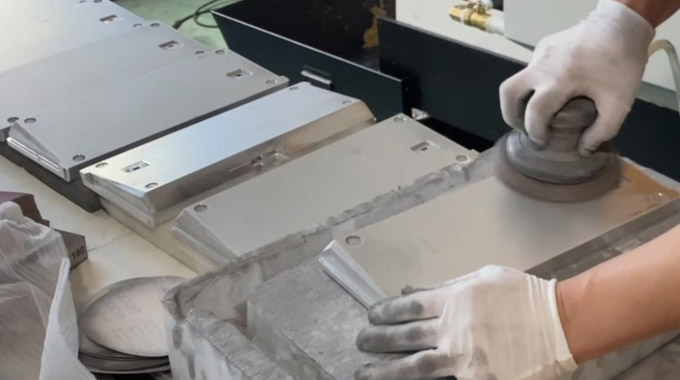

4. Thorough Surface Treatment Preparation:

Implement rigorous surface preparation methods before polishing. This includes sanding, grinding, and other preparatory steps to ensure a smooth starting surface.

5. Precision Polishing Techniques:

Use precision polishing techniques with high-quality abrasives and compounds. Pay attention to the details, including pressure, speed, and tooling, to achieve a consistent and defect-free surface.

6. Automated Polishing Systems:

Consider the use of automated polishing systems for consistency and precision. Automated systems can reduce variability in the polishing process.

7. Robust Quality Control Checks:

Implement robust quality control checks at various stages, including after die-casting, after polishing, and before PVD coating. This ensures that any defects are identified early in the process.

8. Advanced PVD Coating Technologies:

Invest in advanced PVD coating technologies that provide better control over deposition rates, temperatures, and coating uniformity.

9. Strict Environmental Control:

Control the environment during PVD coating to minimize dust, contaminants, and temperature variations that could impact coating quality.

10. Skilled Workforce:

Train and equip the workforce with the necessary skills for polishing and PVD coating. Skilled operators can ensure that processes are executed accurately.

11. Continuous Process Monitoring:

Implement real-time monitoring of key parameters during both polishing and PVD coating. This enables early detection of deviations and allows for prompt corrective actions.

12. Collaborate with Suppliers:

Work closely with material suppliers, polishing abrasive suppliers, and PVD coating service providers. Establish clear communication and quality standards to ensure consistency in the supplied materials and services.

13. Root Cause Analysis:

Conduct thorough root cause analysis whenever defects are identified. Understanding the root causes allows for targeted corrective actions.

14. Implement Lean Manufacturing Practices:

Integrate lean manufacturing practices to streamline processes, reduce waste, and enhance overall efficiency.

15. Regular Process Audits:

Conduct regular process audits to identify areas for improvement and ensure adherence to quality standards.

By implementing these strategies and maintaining a commitment to quality throughout the entire CNC machining production process, you can enhance the yield and overall quality of die-cast CNC machined parts in both polishing and PVD mirror surface treatment.